Second generation small-wave support vector machine assessment method for damage and remaining life of metal structure

A technology of support vector machines and metal structures, which is applied in the testing, measuring devices, instruments and other directions of machines/structural components, and can solve the problems of over-learning of support vector machines, affecting the promotion performance, and under-learning, etc.

Active Publication Date: 2013-05-22

北京南洋思源智能科技有限公司

View PDF5 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical applications, the selection of kernel function parameters makes the support vector machine prone to over-learning or under-learning, which directly affects its generalization performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

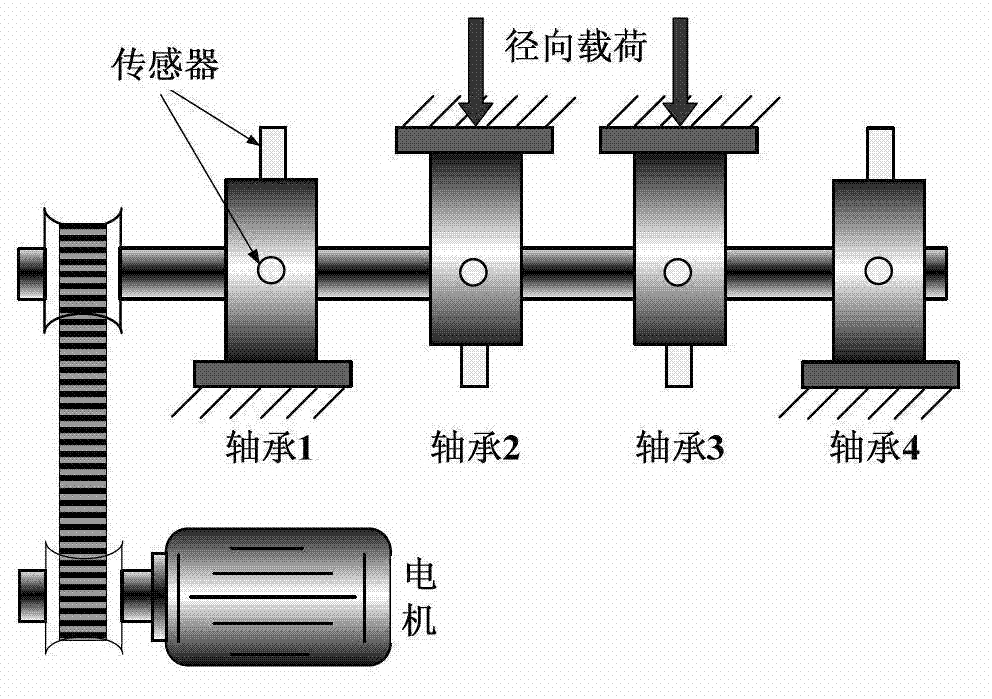

[0071] This embodiment has given the specific implementation process of the present invention in the aviation equipment test, and has verified the validity of the present invention simultaneously.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

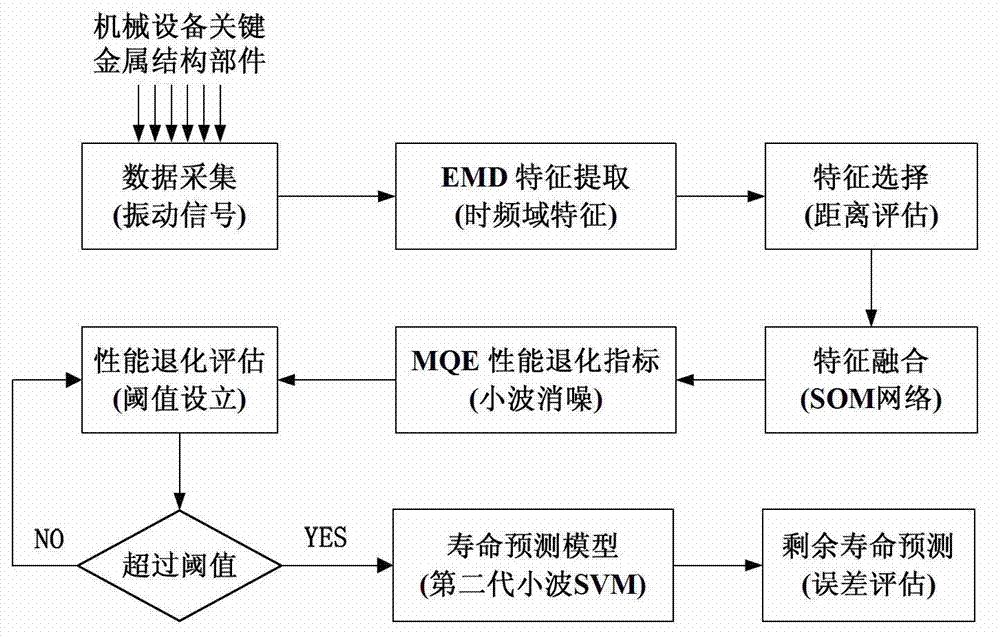

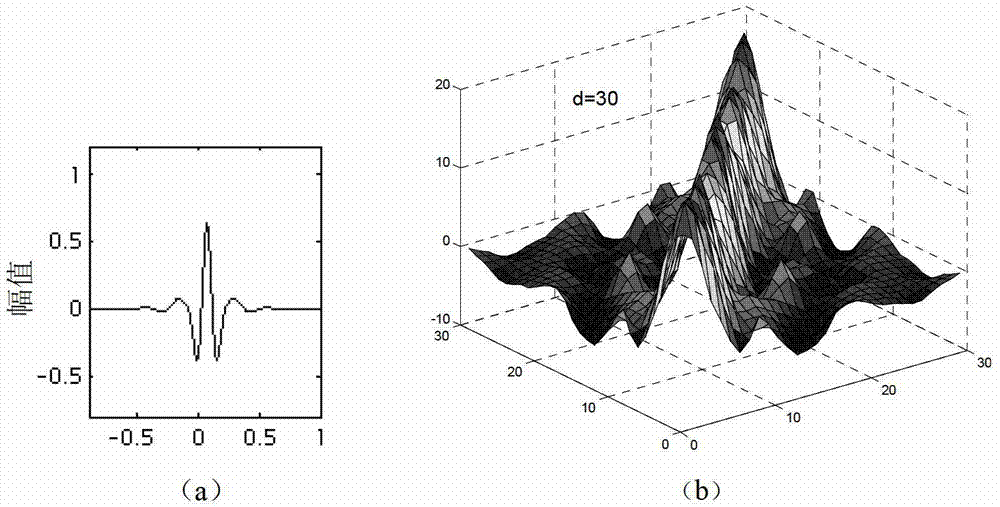

The invention discloses a second generation small-wave support vector machine assessment method for damage and remaining life of a metal structure. According to the method, an intrinsic mode function is obtained through decomposition of an experience mode, a time-frequency domain statistic characteristic of the intrinsic mode function is extracted, a most sensitive characteristic is chosen according to a distance accessment principle to construct a best characteristic set, a minimum quantization error indicator which has an obvious performance degradation trend along with time changes is constructed by means of self-organization neural network characteristic fusion techniques, a biorthogonal small-wave support vector machine kernel function of second generation small-wave transform is provided, a service life prediction model of the second generation small-wave support vector machine is constructed, the minimum quantization error indicator serves as a prediction characteristic, and quantitative assessment for the damage and the remainig service life of a metal structural component of mechanical equipment under a small subsample is achieved.

Description

technical field [0001] The invention belongs to the field of failure prediction of mechanical equipment, and in particular relates to a method for quantitative evaluation of damage failure detection and remaining life of key metal structural components. Background technique [0002] With the increasing requirements of modern warfare on the attendance rate and combat readiness rate of weapons and equipment, and the rapid development of material science, testing technology, signal analysis and artificial intelligence technology, a large number of weapons and equipment currently use failure prediction and state management technology (Prognostic and Health Management, PHM) to achieve "condition-based maintenance", that is, preventive maintenance based on conditions. This technology detects the state of the system to predict the failure of the system and its components, and determines its remaining life; it uses multi-sensor information fusion technology to diagnose system failur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M99/00

Inventor 陈雪峰刘治汶申中杰何正嘉孙闯

Owner 北京南洋思源智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com