Automated liquid supply mechanism and coater provided with same

A technology of automatic supply and coating device, which is applied to the device for coating liquid on the surface, liquid degassing, coating and other directions, which can solve the problem of mixing air bubbles or foreign matter, reducing productivity and work efficiency, and increasing the amount of liquid crystal used. It can prevent the generation and mixing of particles, eliminate the deterioration of the liquid supply channel, and prevent the inflow of air bubbles into the discharge device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

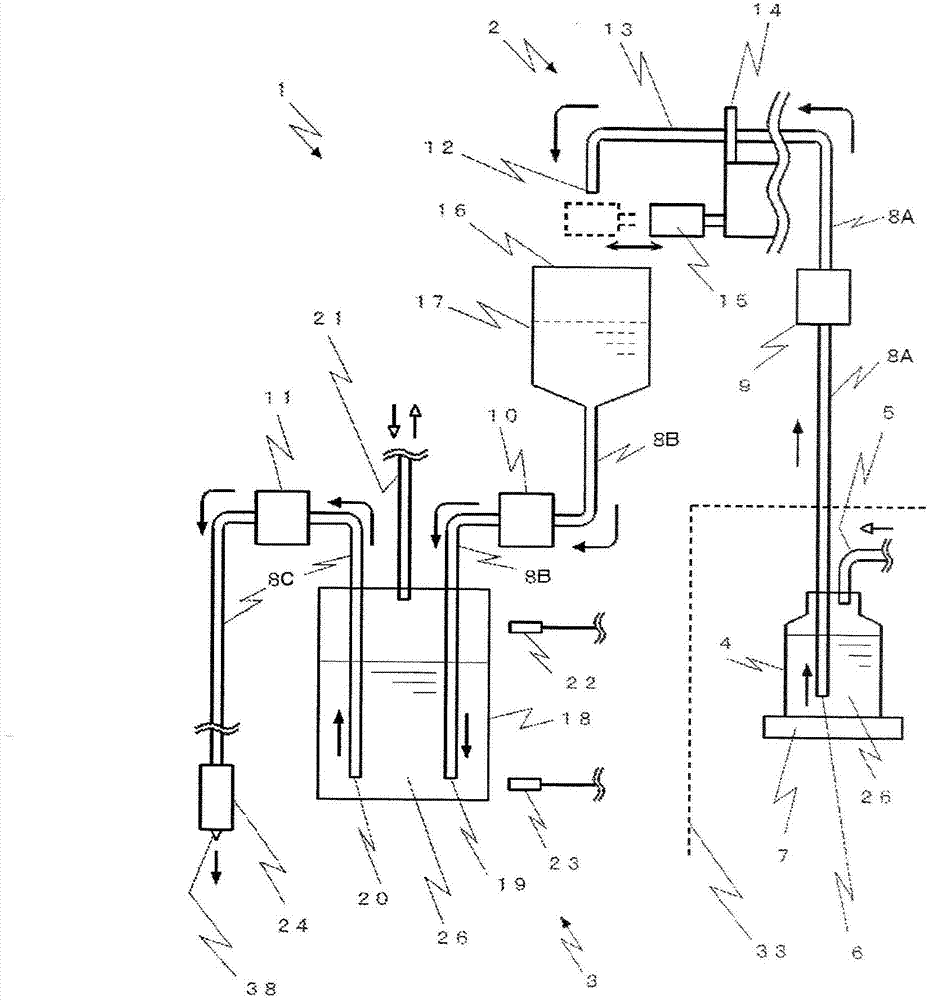

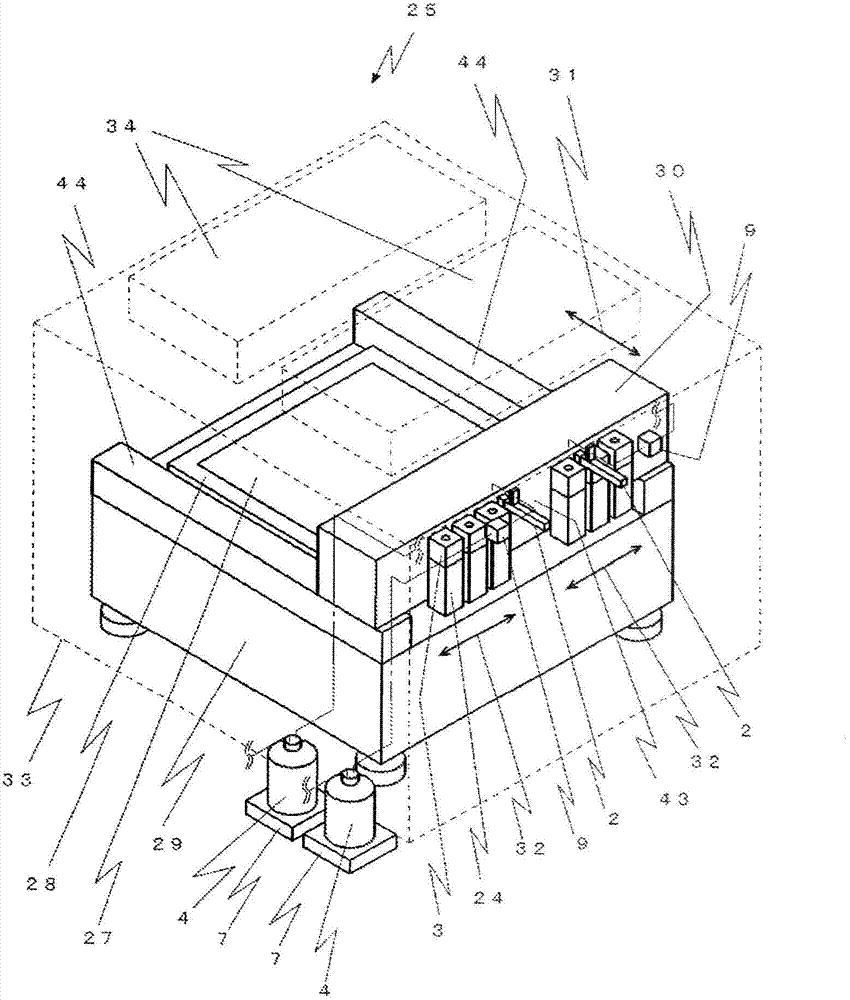

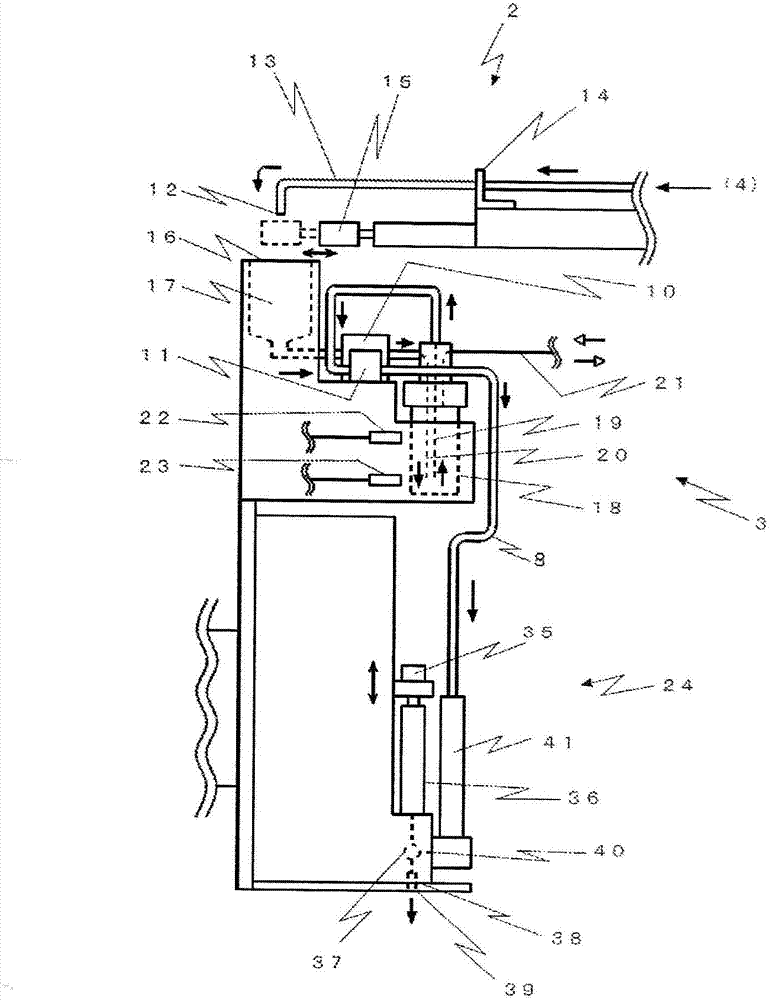

[0054] The embodiment relates to a coating device, which is a coating device that applies liquid crystal to a workpiece while relatively moving a discharge device and a table holding a workpiece, and is called a so-called gantry type in which a beam moves on a table. .

[0055] figure 2 A schematic perspective view showing a coating device equipped with an automatic liquid supply mechanism according to an embodiment, image 3 It shows an enlarged view of main parts of the automatic feeding mechanism according to the embodiment. Below, explain figure 2 Sometimes, the side where the tank 4 is installed is called "left", the opposite side (symbol 9 side) is called "right", the side where the discharge device 24 is installed is called "front", and the opposite side is called "front". The side is called "rear". In addition, the left-right direction is referred to as "X direction", and the front-rear direction is referred to as "Y direction".

[0056] like figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com