Reduction device

A technology of reduction gear and eccentric circle, which is applied in the direction of transmission, gear transmission, shaft installation, etc., can solve the problem of longer axial length of the reduction gear, and achieve the effect of reducing resistance and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

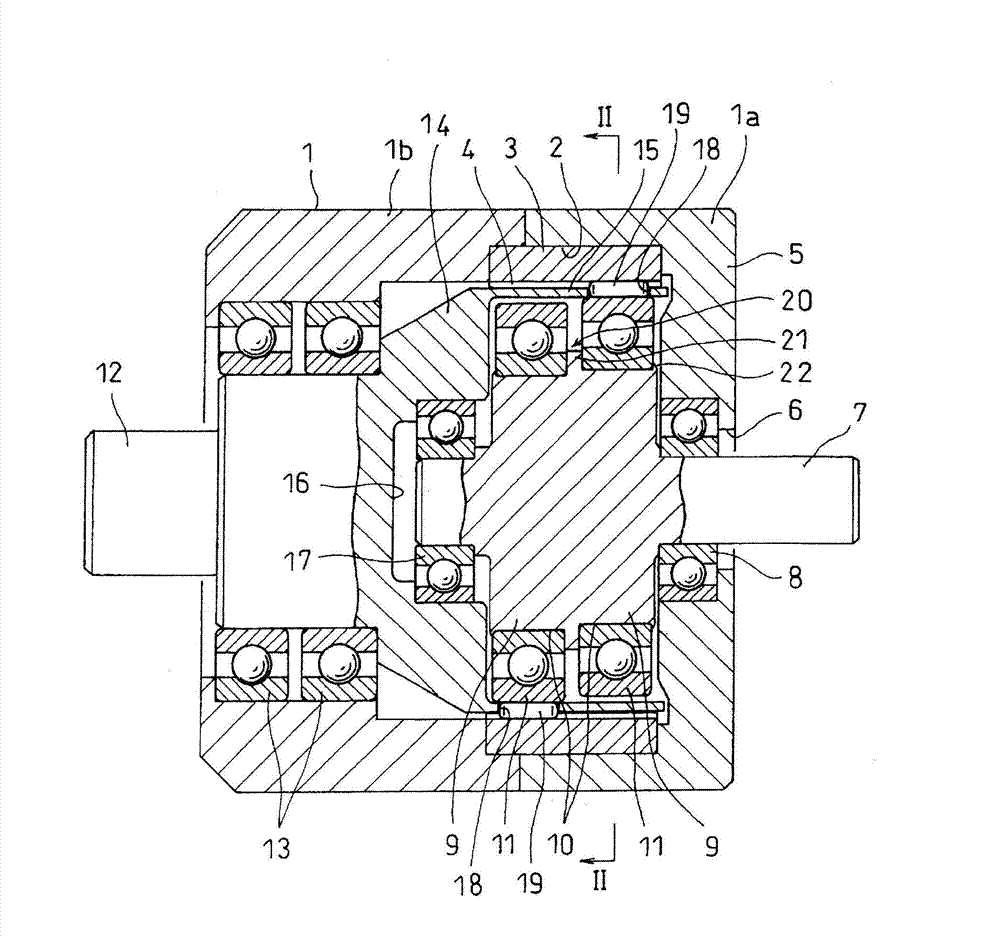

[0074] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 As shown, the housing 1 is cylindrical. The housing 1 is divided into two parts in the axial direction, and a first divided housing 1a and a second divided housing 1b are provided.

[0075] The first split case 1a and the second split case 1b are integrally fastened by bolts (not shown), and formed so as to straddle the first split case 1a and the second split case 1b on the inner diameter surface of the end portion on the abutting side. There is a large-diameter concave portion 2 .

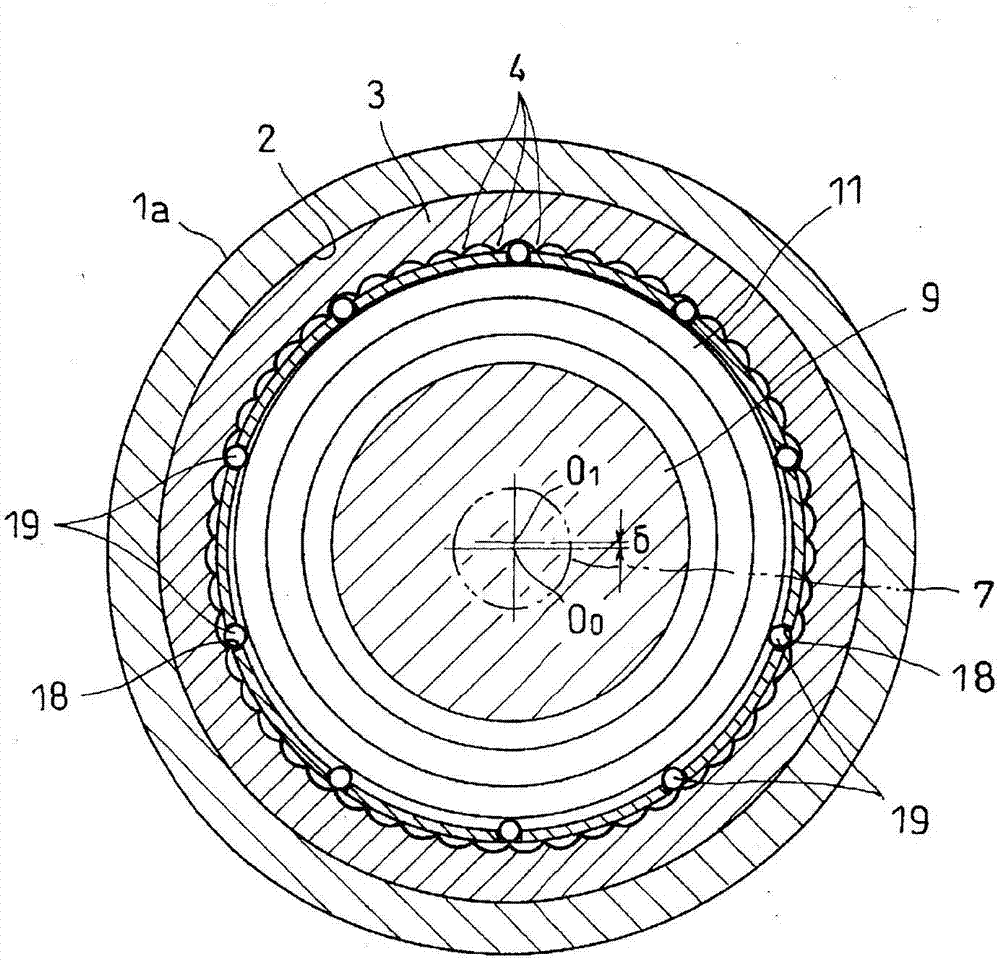

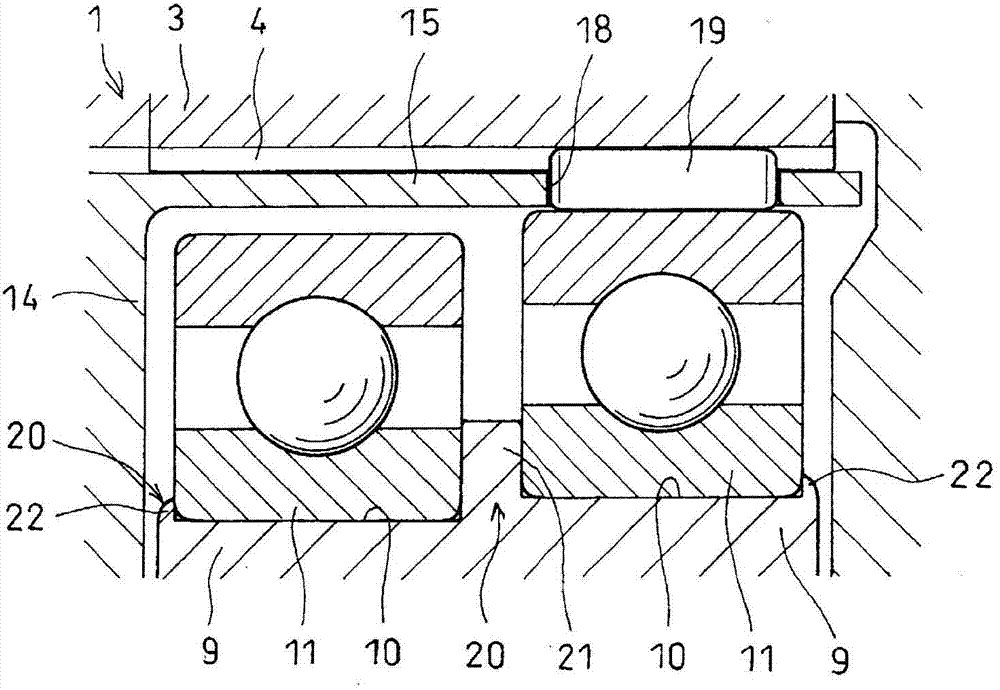

[0076] Such as figure 1 and figure 2 As shown, an internal gear 3 is pressed into the large-diameter concave portion 2 , and a plurality of internal teeth 4 are provided on the inner periphery of the internal gear 3 .

[0077] Such as figure 1 As shown, an end plate 5 is provided at an opening end portion of the first divided case 1a, and an input shaft 7 is inserted into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com