Valve core forming and cutting process and integrated mold

A molding die and spool technology, applied in metal processing, etc., can solve problems such as non-standard spool cuts, complicated process, and low production efficiency, and achieve the effects of improving product qualification rate, reducing professionals, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

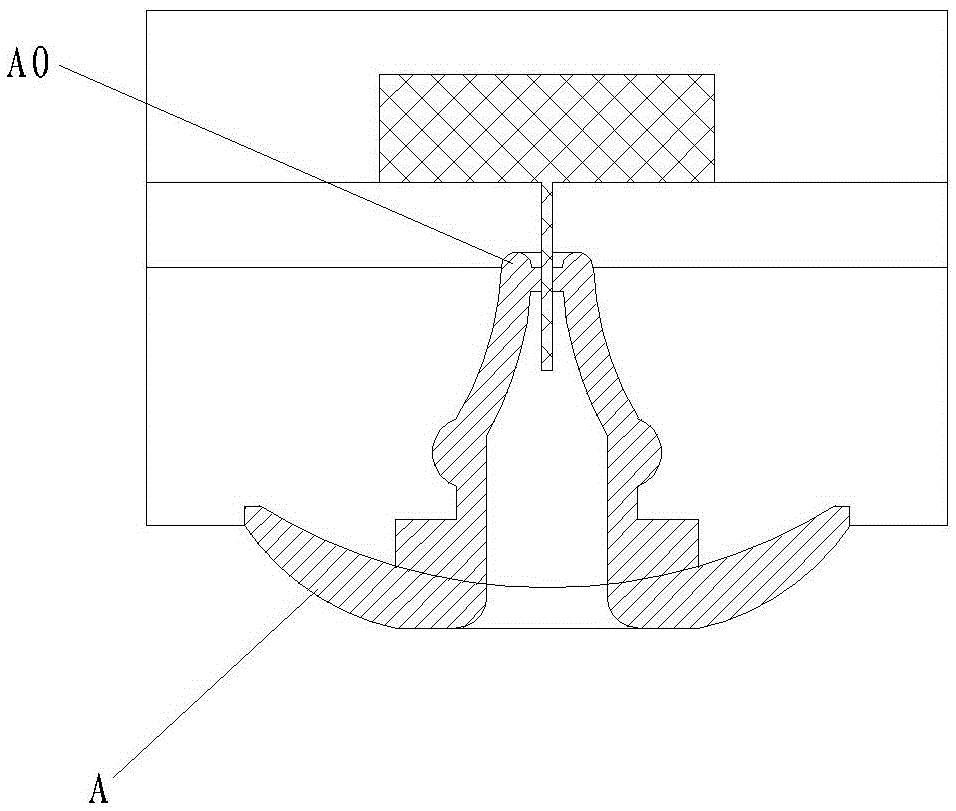

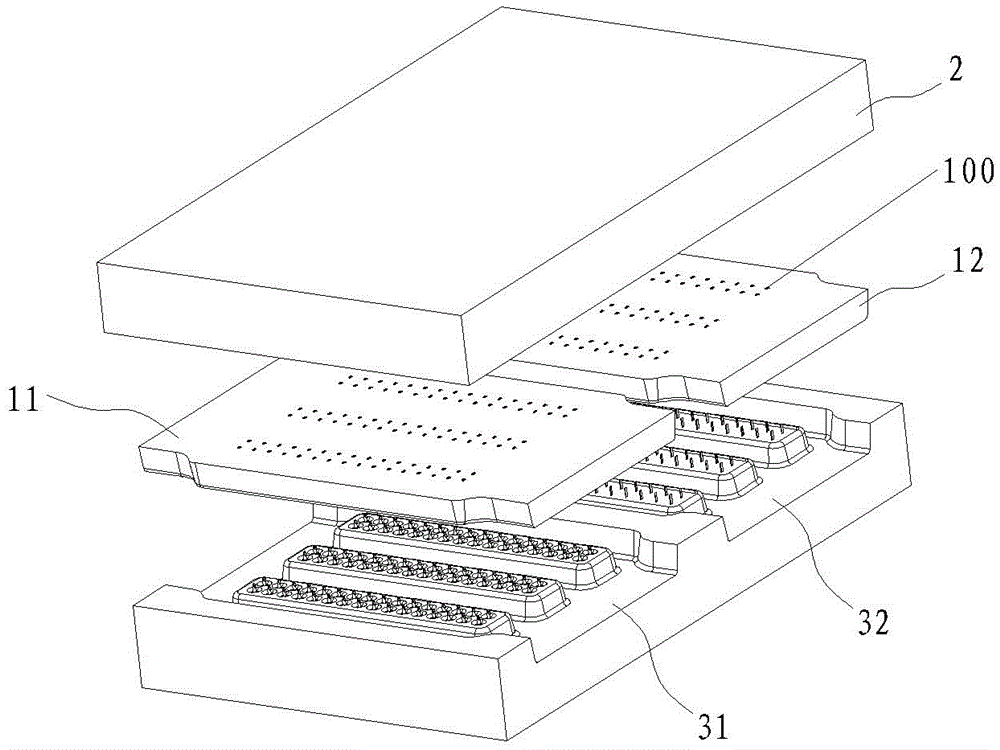

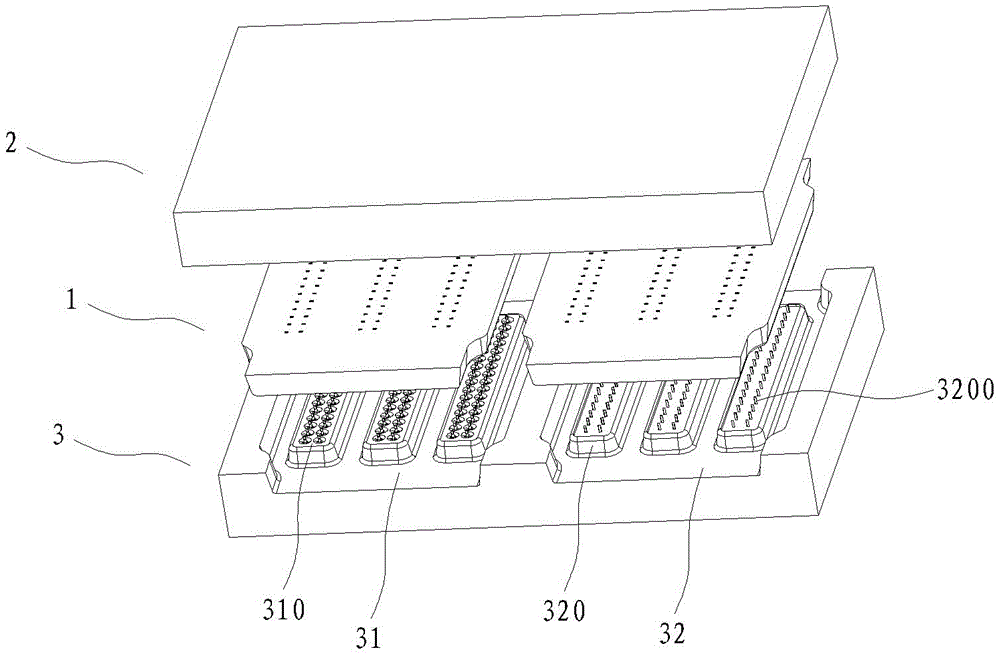

[0024] Example: see Figure 2 to Figure 4 , a valve core forming and cutting integrated mold, including an upper die 1, an upper template 2 and a lower die 3, wherein the upper die 1 is composed of two independent forming dies 11 and a notch die 12, the forming die 11 and the notch The mold 12 is movably installed on the upper template 2 through the positioning guide pillars; the lower mold 3 is provided with a molding area 31 and a notch area 32, and cooperates with the forming mold 11 and the notch mold 12 of the upper mold to form several valve core cavities and notches Cavities are provided with through holes 100 on the top surface of each cavity of the forming die 11 and the notch die 12, and the notch area 32 of the lower die is provided with a cutter 3200 that cooperates with each notch cavity, and each cutter 3200 is cut from the spool The inner hole at the big end penetrates and extends to the upper template. The molding area of the lower mold 3 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com