Rotary buncher

A concentrator and rotary technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing the tension of the original fiber tow, generating filaments, and wearing the concentrator wheel, so as to prolong the service life, reduce the splitting, avoid the The effect of local wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

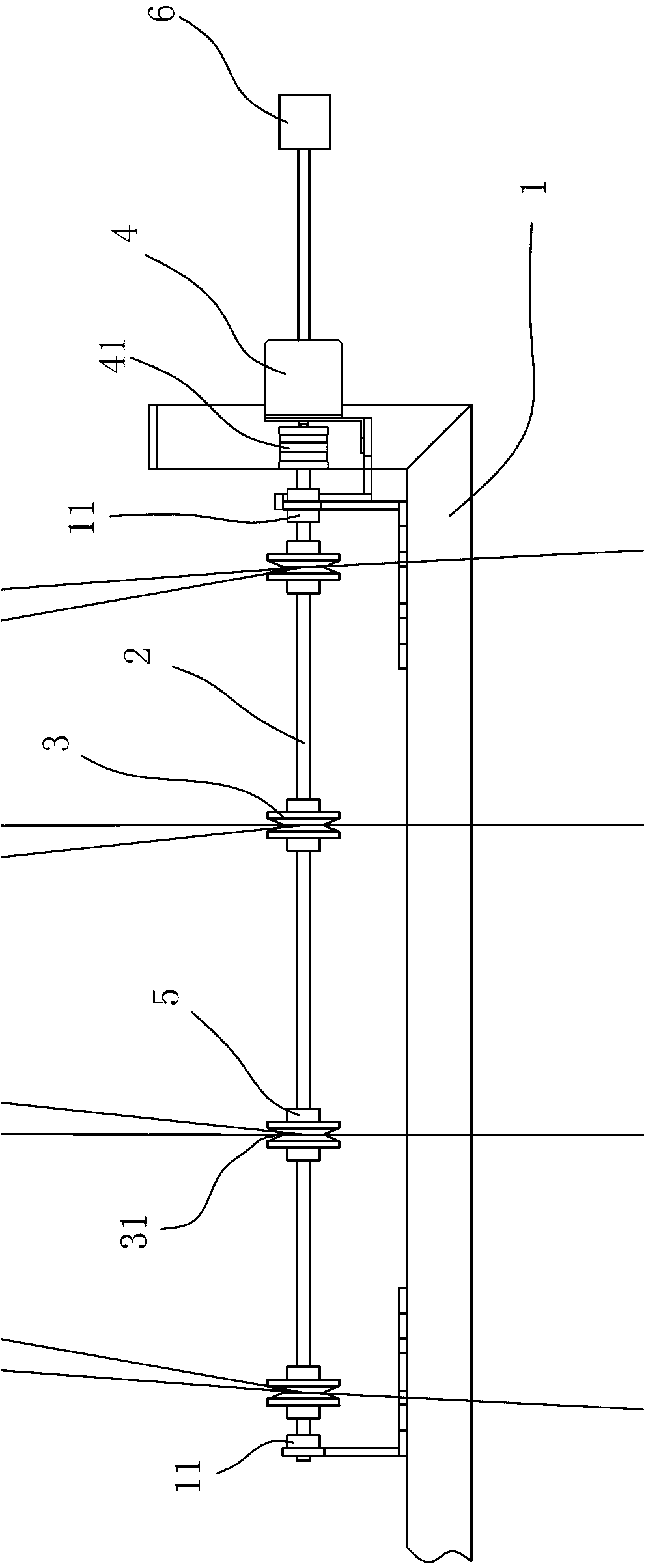

[0012] refer to figure 1 , a kind of rotary buncher of the present invention, comprises support 1, the bunching shaft 2 that is arranged on the bracket 1, and several bunching wheels 3 that are arranged on the bunching shaft 2, is also provided with motor 4 on the bracket 1, and motor 4 and bunching The shaft 2 is connected by transmission, and the motor 4 is also connected with an intermediate relay 6 .

[0013] The rotary clusterer is provided with a motor 4 and an intermediate relay 6 connected to the cluster shaft 2, and the control signal is connected to the intermediate relay 6 to control the rotation of the motor 4, so that the cluster wheel 3 on the cluster shaft 2 is driven by the motor 4 Rotate slowly and periodically. During the periodical rotation of the cluster wheel 3, the part where the tow is in contact with the cluster wheel 3 is not limited to one place on the cluster wheel 3, but multiple places are in contact with the cluster wheel 3 periodically. , so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com