Photosynthetic cultivation fermentation device

A fermentation device and lighting device technology, applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermenter combinations, etc., can solve the problem of insufficient lighting energy, prolong the fermentation cycle, and limit the light intensity of the fermenter, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

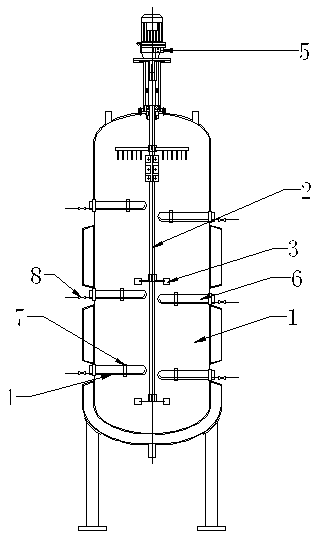

[0013] Such as figure 1 As shown, the photosynthetic culture fermentation device of the present invention comprises a tank body 1 with a jacket, a stirring device 5, and an illumination device 6, the stirring device 5 is fixedly arranged on the upper side of the tank body 1, and the stirring device 5 The stirring shaft 2 extends into the tank body 1, and the stirring shaft 2 is provided with more than one stirring blade 3 along the axial direction; the illuminating device 6 is arranged on the tank body 1, and the illuminating device 6 of this embodiment is staggered along the axial direction of the tank body 1 at intervals Arrangement, the lighting device 6 is radially and uniformly arranged from the radial center of the tank body 1, so that the lighting device 6 can evenly irradiate the tank body without leaving any dead angle, and the fermentation efficiency can be improved. The lighting device is also provided with a cooling pipe 4; when the temperature needs to be precisel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com