Magnetic liquid damp shock absorber

A technology of magnetic liquid and shock absorber, which is applied in the direction of spring/shock absorber, magnetic spring, spring, etc., can solve the problems of reduced service life of shock absorber, high quality of permanent magnet, and poor processing technology, so as to reduce quality, The effect of reducing launch cost and increasing vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with accompanying drawing:

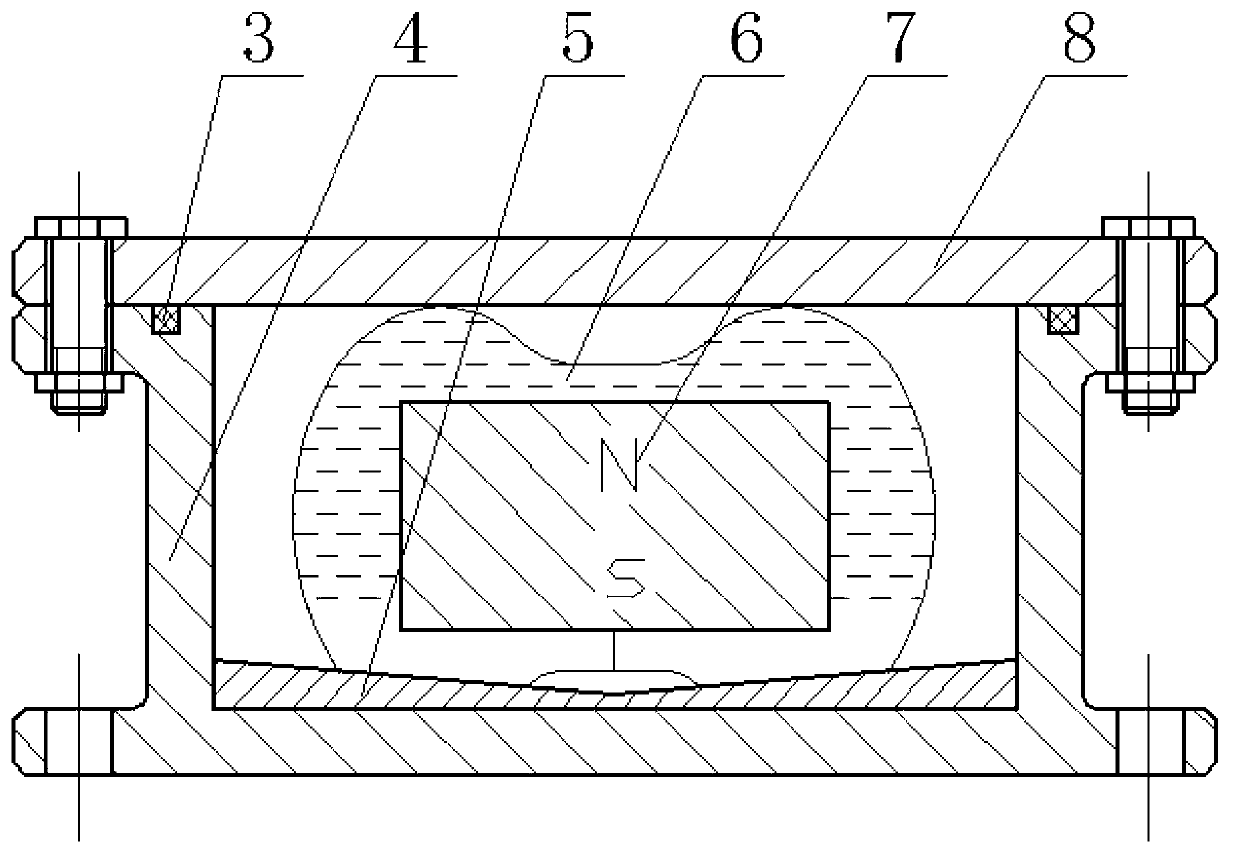

[0014] A magnetic liquid damping shock absorber, such as figure 1 , the damping device includes: O-shaped rubber sealing ring 3, housing 4, magnetic liquid 6, rubber cylindrical magnet 7, end cover 8; O-shaped rubber sealing ring 3 is embedded in the groove on the open end surface of the housing 4, and the magnetic The liquid is adsorbed on the rubber cylindrical magnet 7, and the end cover 8 and the housing 4 are tightly connected together by bolts and nuts.

[0015] The wedge-angle gasket 5 is placed on the bottom of the housing 4 , and its V-shaped included angle is upward, and the rubber cylindrical magnet 7 adsorbing the magnetic liquid 6 is placed in the housing 4 .

[0016] The rubber cylindrical magnet 7 is axially magnetized, and the axis is placed perpendicular to the horizontal plane.

[0017] The V-shaped included angle of the wedge-angle gasket 5 is 60-170 degrees,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| V-shaped angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com