Evaluation and design machining methods of double-faced free-form surface lens

An evaluation method and lens technology, applied in the fields of glasses/goggles, optics, instruments, etc., can solve the problems of waste, long design cycle, and no consideration of the optical system of the lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

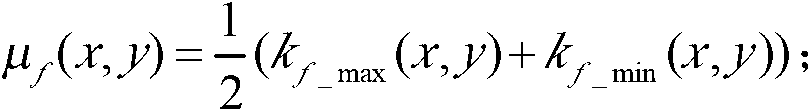

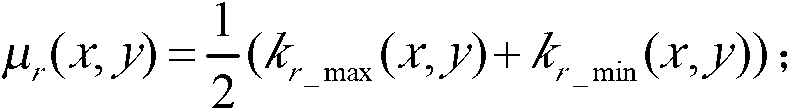

[0059] In this embodiment, the parameters of the lens to be processed are obtained by optometry: the power of the lens in the far vision area is 0 diopters, and the amount of light added between the far vision point and the near vision point is 2 diopters. The design parameters of the front surface are: the power of the far point lens is 3 diopters, and the amount of light added between the far point and the near point is 1 diopter. The design parameters of the rear surface are: the power of the far point lens is 3 diopters, and the light reduction between the far point and the near point is 1 diopter.

[0060] The lens parameters of the lens to be processed: the diameter is 72mm, the refractive index is 1.523, the distance from the pupil to the lens is 14mm, and the center thickness of the lens is 3mm.

[0061] See attached figure 1 , which is a schematic diagram of the divisions of progressive multifocal ophthalmic lenses.

[0062] See attached figure 2 , which is a sche...

Embodiment 2

[0092] In this embodiment, the parameters of the lens to be processed are obtained by optometry: the power of the lens at the far point of vision is -2 diopters, and the amount of light added between the far point of vision and the near point of vision is 2 diopters. The design parameters of the front surface are: the diopter of the far point lens is 1.5 diopters, and the amount of light added between the far point of vision and the near point of vision is 0.75 diopters. The design parameters of the rear surface are: the diopter of the far point lens is 3.5 diopters, and the light reduction amount between the far point of view and the near point of vision is 1.25 diopters.

[0093] The lens parameters of the lens to be added: the diameter is 72mm, the refractive index is 1.6, the distance from the pupil to the lens is 14mm, and the center thickness of the lens is 3mm.

[0094] The implementation steps are as in Embodiment 1, and the following drawings are obtained:

[0095] s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com