Antibacterial medical fabric

A kind of fabric and medical technology, applied in the field of new medical fabrics, can solve the problems of increasing the burden of medical workers, reducing the breathability of fabrics, reducing flexibility and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, and to make the above-mentioned objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail with reference to the embodiments and the accompanying drawings. .

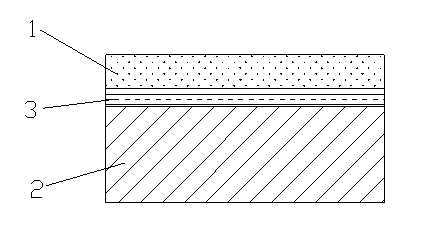

[0017] Such as figure 1 Shown is a schematic structural diagram of an antibacterial medical fabric according to an embodiment of the present invention; the fabric is composed of a surface layer 1 and an inner layer 2. The surface layer 1 is a waterproof antibacterial film layer, and the inner layer 2 is a fabric layer , The adhesive 3 is coated between the surface layer 1 and the inner layer 2 to achieve close adhesion.

[0018] The main raw material of the surface layer 1 of the antibacterial medical fabric mentioned in the present invention is thermoplastic polyurethane, which contains quantitative nano silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com