Mobile suction device

A technology of attraction device and detection circuit, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of inconvenient maintenance, complicated circuit structure, and high failure rate, so as to reduce the failure rate, increase computing functions, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

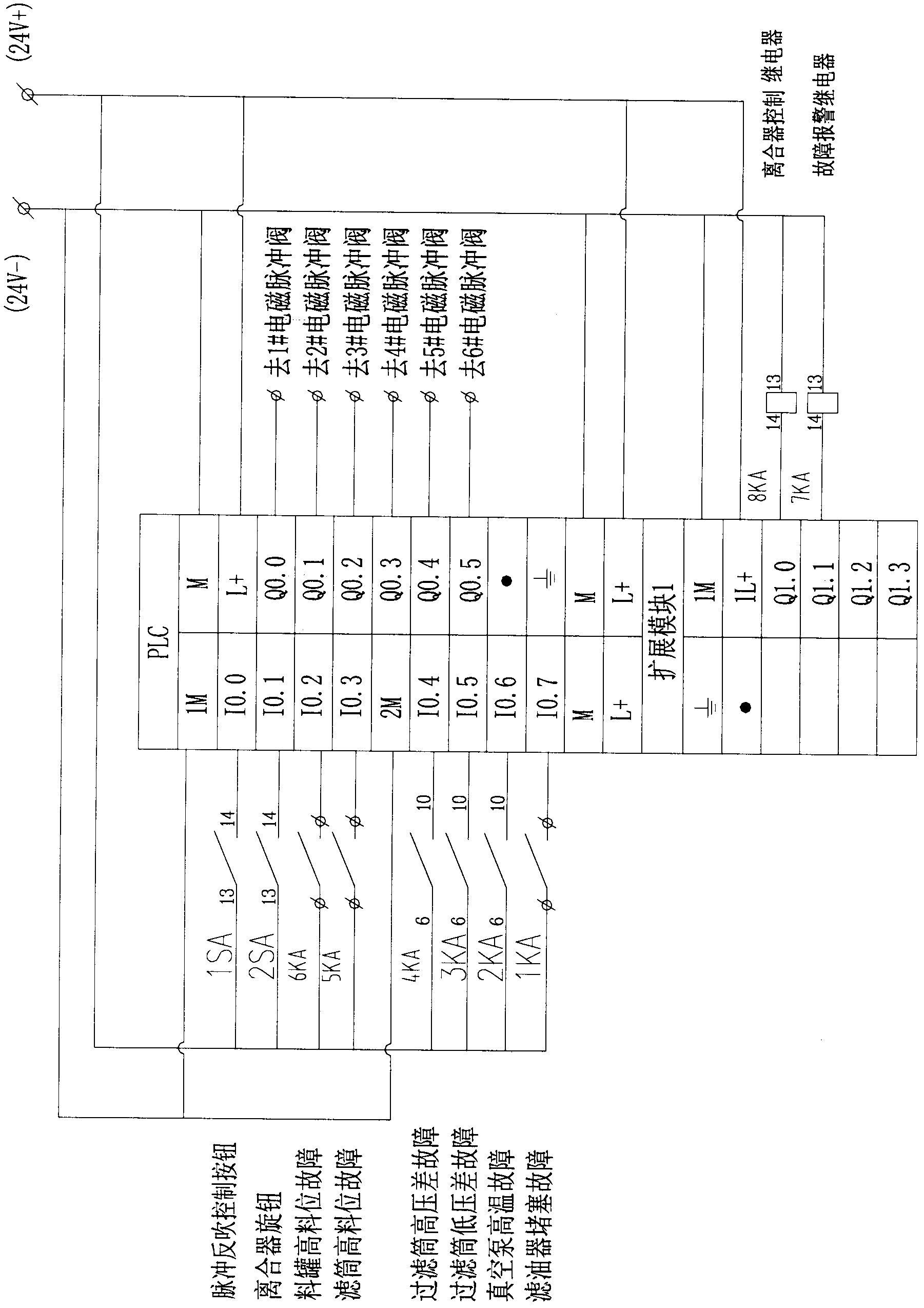

[0009] like figure 1 As shown, the control circuit of the mobile suction device of the present invention includes a programmable logic controller PLC, a pulse blowback control button, a clutch knob, a high material level detection circuit for a material tank, a high material level detection circuit for a filter cartridge, and a differential pressure detection circuit for a filter cartridge , Vacuum pump high temperature detection circuit, oil filter blockage fault detection circuit, electromagnetic pulse valve, clutch control relay, fault alarm relay. The pulse blowback control button, the clutch knob, the high material level detection circuit of the material tank, the high material level detection circuit of the filter cartridge, the differential pressure detection circuit of the filter cartridge, the high temperature detection circuit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com