Novel structure and new welding method of oil inlet and outlet of hydraulic cylinder

A technology of oil inlet and outlet and hydraulic cylinder, which is applied in welding equipment, fluid pressure actuating devices, workpiece edge parts, etc., can solve the problems of long process and unfavorable cylinder productivity, and achieve small current, lower requirements, and reduced internal Effects of Stress and Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

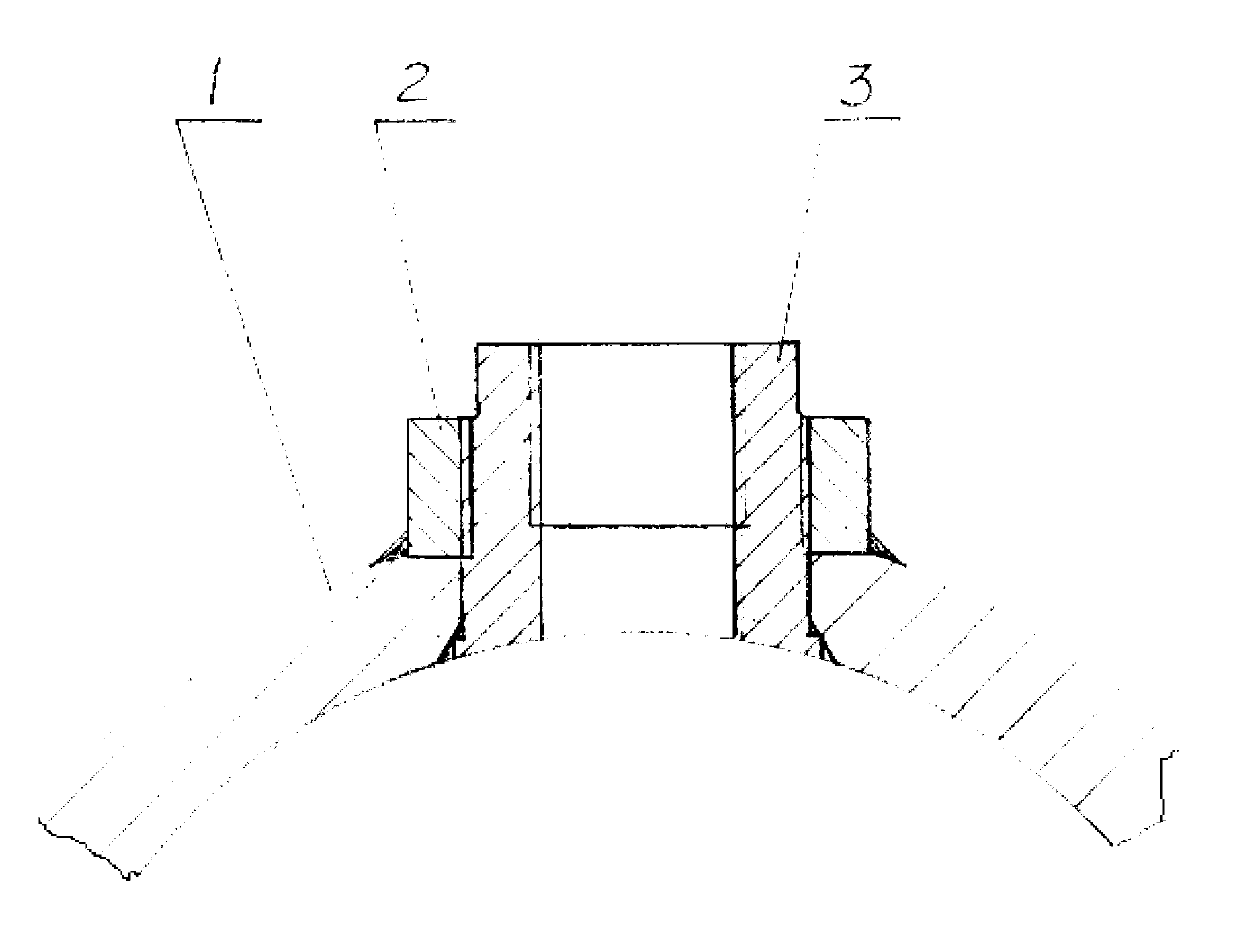

[0012] The specific embodiment of the present invention is: first, the upper part of the cylinder body 1 is a cylindrical hole and the lower part is an inner tapered hole larger than the upper cylindrical hole. The installation hole of the joint body 2 and the matching step-shaped oil inlet and outlet joint After the body 2 is processed, the joint body 2 is assembled from the inside of the cylinder body 1 from the inside to the outside, and then the joint body 2 is tightened upward with the nut 3, so that the outer circle of the larger step is at right angles to the cylinder body 1. After the mechanical seal pair composed of the inner cone surface is locked and sealed, the outer circle of the nut 3 is welded to the cylinder body 1, the joint body 2 and the nut 3 with a small welding current and welding seam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com