Elevator guide rail automatic machining production line and production technology thereof

An elevator guide rail and automatic processing technology, applied in the field of CNC machine tools, can solve the problems of long production line length, etc., and achieve the effects of saving installation space, compact structure, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

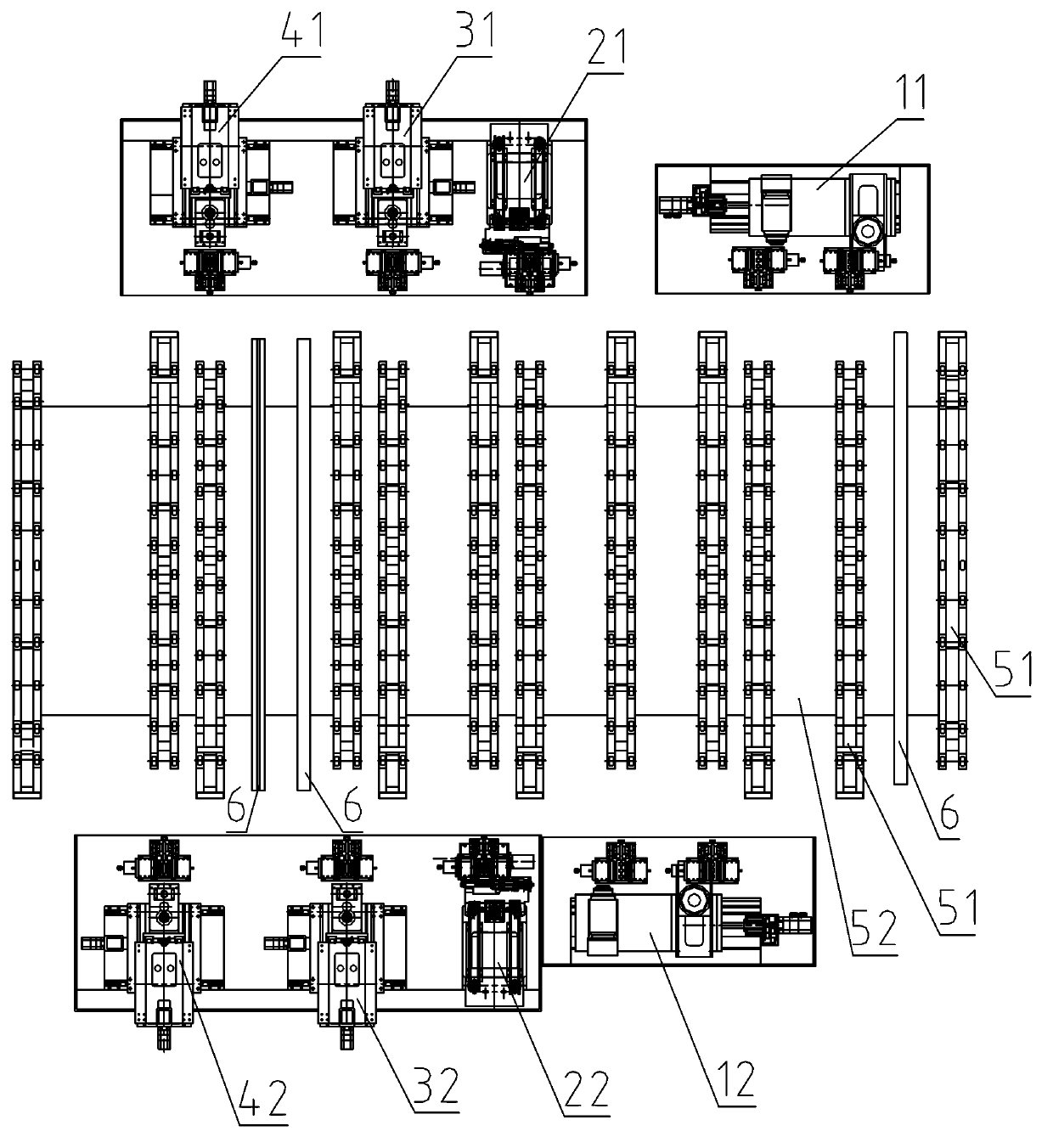

[0024] Such as figure 1 As shown, an elevator guide rail automatic processing production line includes an elevator guide rail milling processing unit, an elevator guide rail male and female tenon processing unit, an elevator guide rail mounting hole processing unit, an elevator guide rail countersinking processing unit, and a conveying and feeding system.

[0025] The elevator guide rail milling processing unit, the elevator guide rail male and female tenon processing unit, the elevator guide rail mounting hole processing unit and the elevator guide rail countersinking processing unit are horizontally arranged side by side.

[0026] The elevator guide rail milling processing unit comprises a first elevator guide rail milling processing device 11 and a second elevator guide rail milling processing device 12, and the two elevator guide rail milling processing devices face to face are arranged on both sides of the conveying and loading device 5, and are vertically staggered by one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com