Fluffy fiber cotton roll packaging machine

A fiber and cotton lap technology, applied in the field of fluffy fiber cotton lap balers, can solve problems such as damage to fiber elasticity, and achieve the effects of reducing operating strength, facilitating transportation, and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

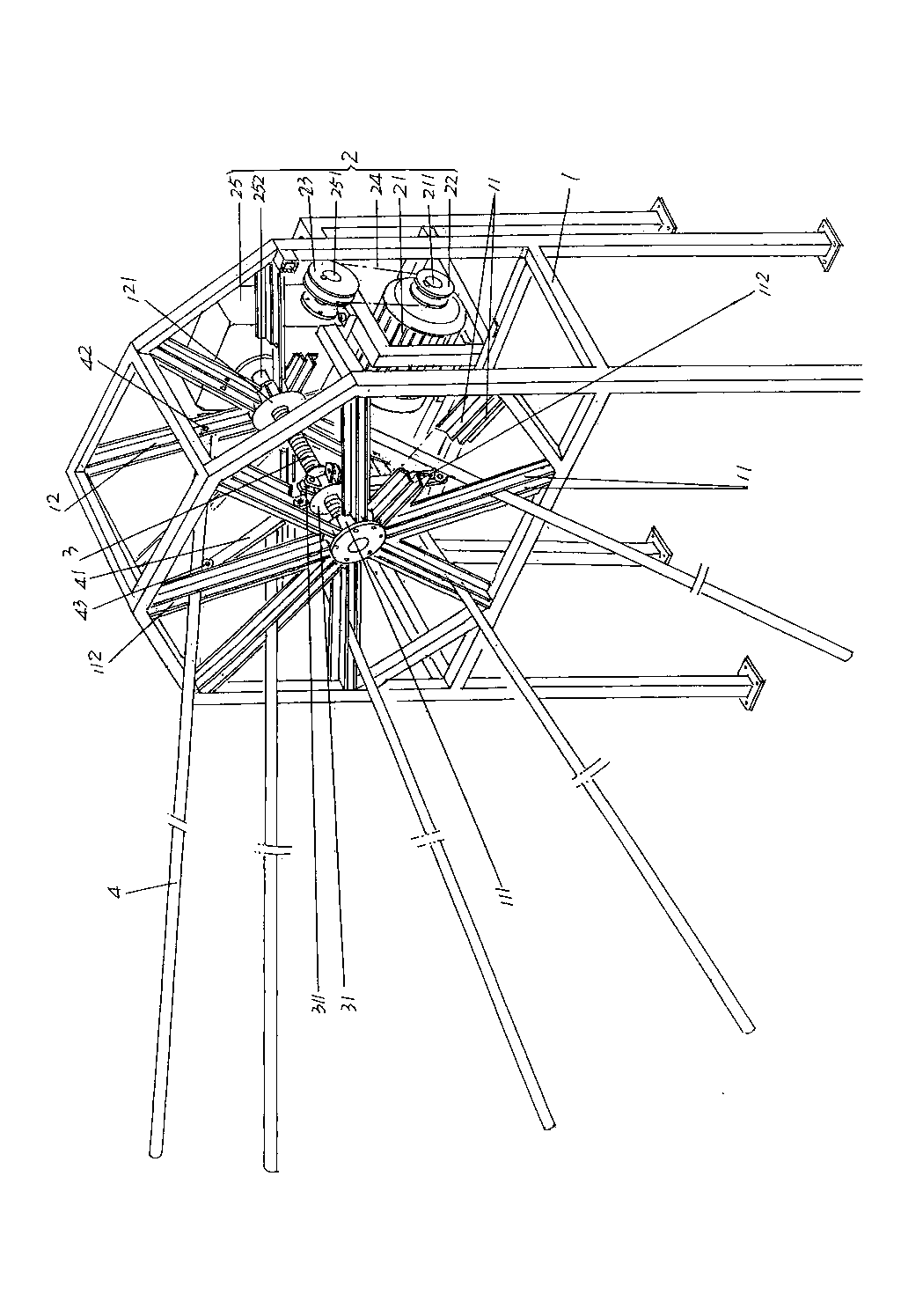

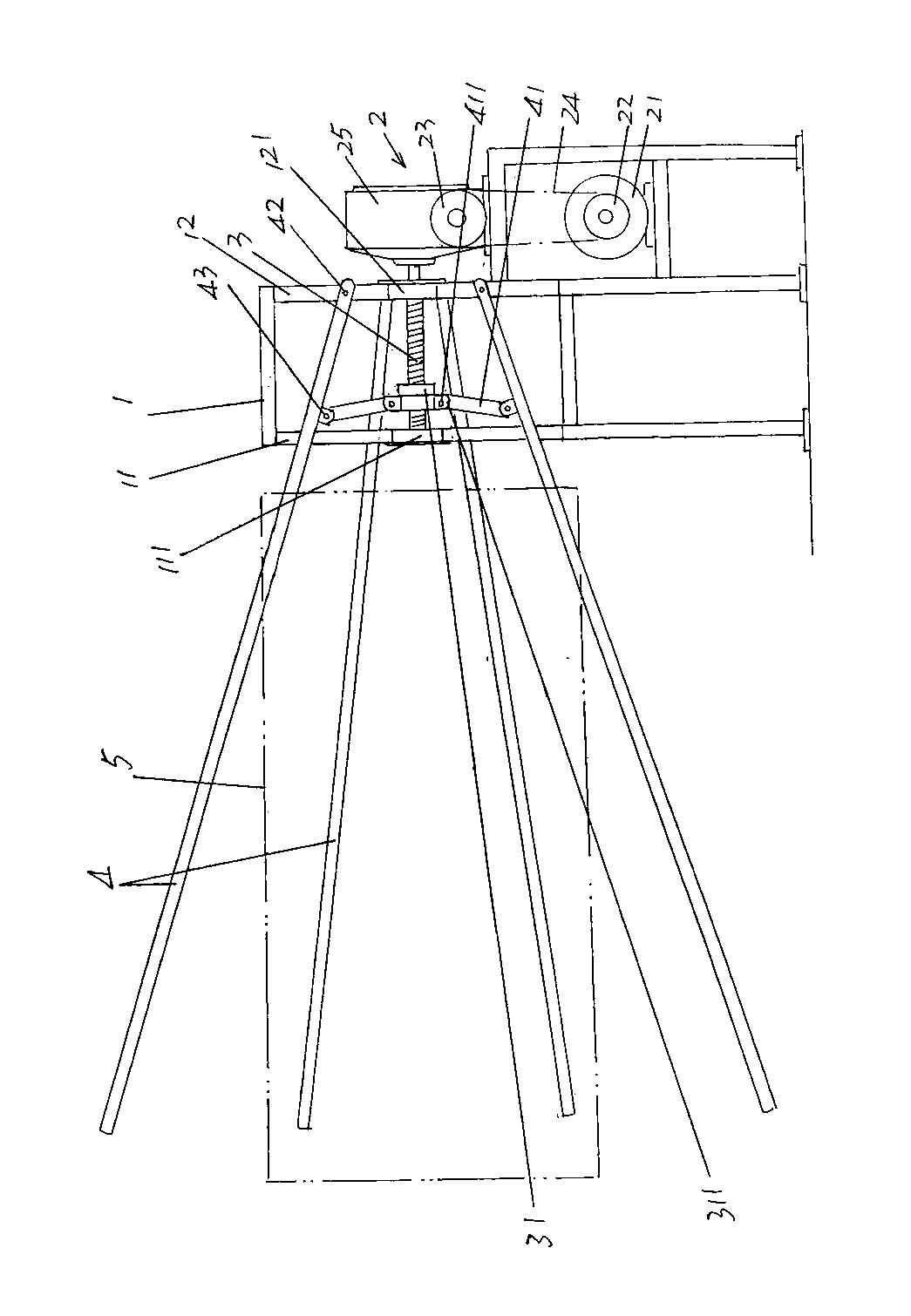

[0017] See figure 1 , a frame 1 preferably formed by welding rectangular pipes with a rectangular cross-sectional shape is provided, and currently consists of figure 1 The shown position state is taken as an example. On one side of the upper part of the frame 1, that is, the front side, a group of first pressing claw rod guide rails 11 are fixed in a radial form (radiation state). In this embodiment, a group of first pressing claws The number of rod guide rails 11 is eight of the same length, and the spacing between adjacent first claw rod guide rails 11 is equal, but the quantity of the first pressure claw rod guide rails 11 should not be limited by the number shown in the figure, for example both It can be as few as three at least, and can be as many as more than eight. In view of this, the technical solution of the present invention should not be limited by the increase or decrease in the number of the first claw bar guide rails 11 . There is a front bearing seat 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com