Assembly Structure of Automobile Pedal Lock

An automobile pedal and assembly technology, which is applied to vehicle parts, anti-theft vehicle accessories, transportation and packaging, etc., can solve the problems of heavy weight, unsuitability, and high cost, simplify production and assembly procedures, reduce production and processing costs, The effect of reducing production and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

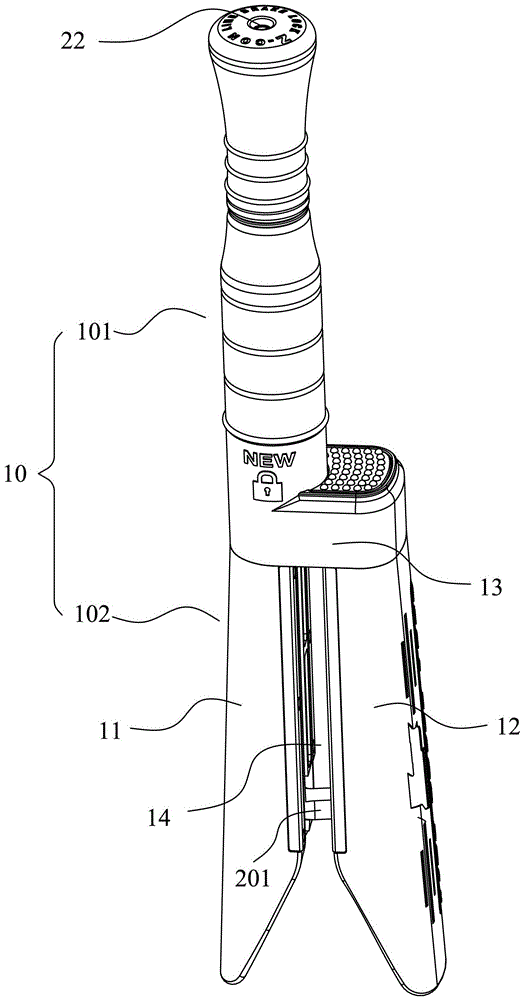

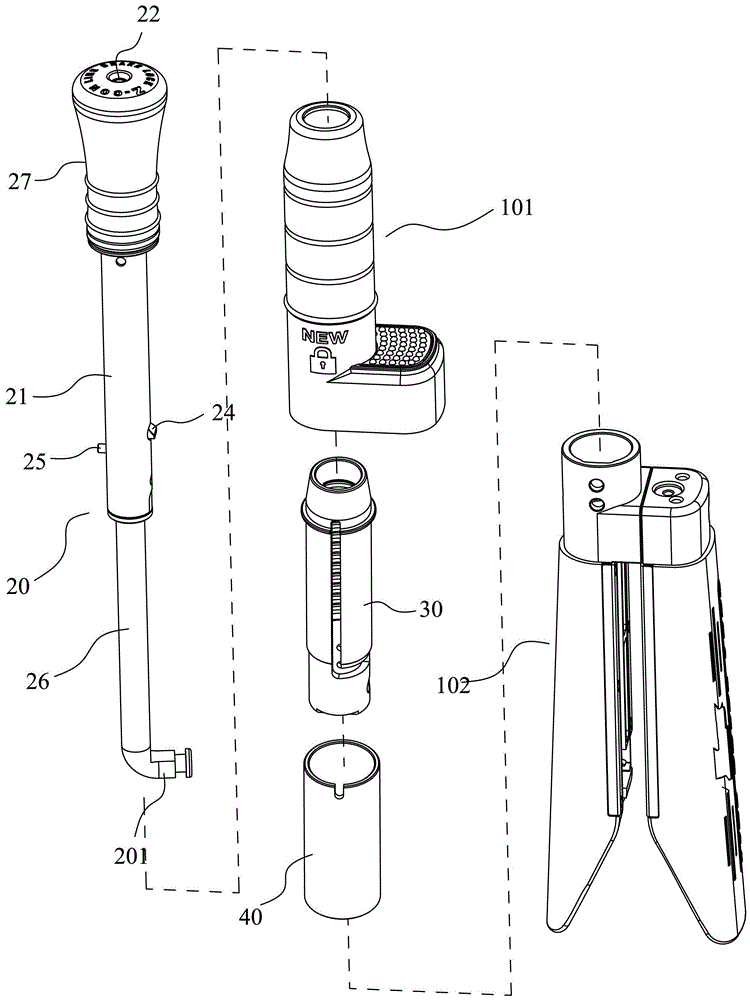

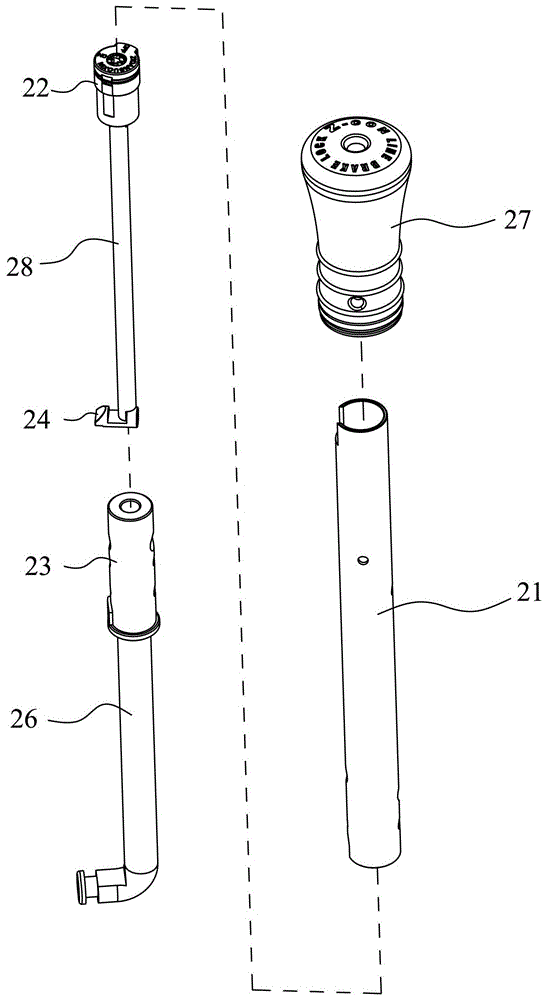

[0052] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including the lock body 10 and the inner telescopic assembly 20, through the rotation of the inner telescopic assembly 20 and the axial up and down telescopic activities, the lockset can be used for the automobile pedal lock and unlock functions. When in the unlocked state, the hook 201 at the lower end of the inner telescopic assembly 20 is hidden in the lock body 10-clamp arm 11; The opening of the clamping groove 14 moves upwards with the inner telescopic assembly 20, and the hook 201 can slide upwards to the lower edge of the shaft hooked on the car pedal, thereby limiting the car pedal from being stepped on and realizing locking.

[0053]The lock body 10 includes an upper fitting part 101 and a lower clamping part 102, the fitting part 101 is used to cooperate with the aforementioned inner telescopic assembly 20, and the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com