An automatic distribution system and automatic distribution method for metal blank cakes

An automatic distribution and metal billet technology, applied in the field of logistics, can solve the problems of low production automation, large equipment footprint, long material transportation process, etc., and achieve continuous and efficient automatic feeding, high production efficiency, and reduce logistics links. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

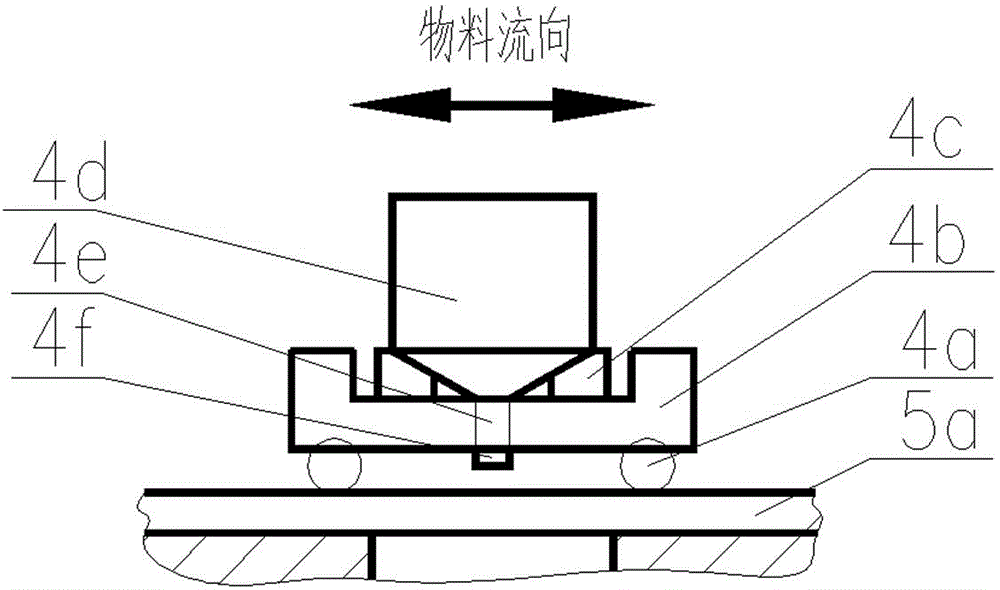

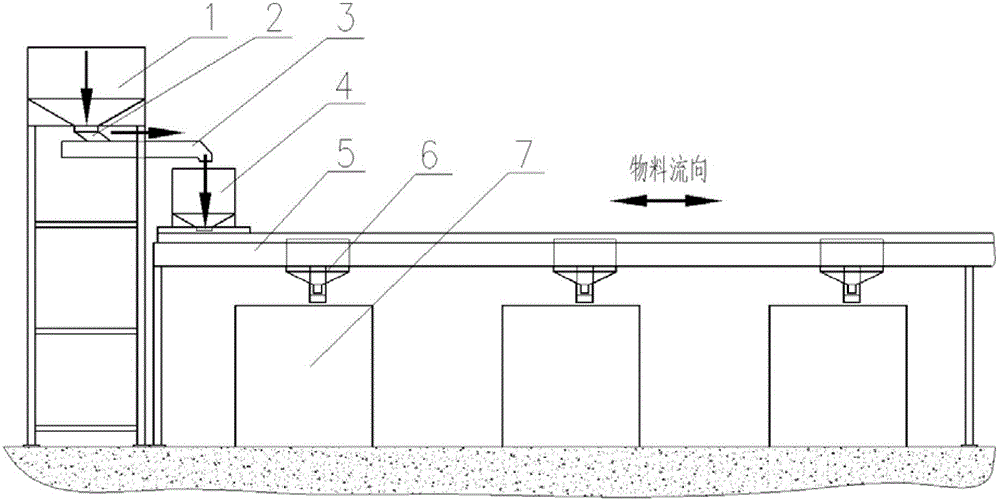

[0011] The automatic distributing system of metal flat cake of the present invention is as figure 1 , figure 2 As shown, this includes a storage bin 1 for caching metal blank cakes with a blanking opening 2 at the bottom. The bottom of the platform 5 reciprocating horizontally has a discharge port 4e and a distribution vehicle 4 that can be weighed automatically, and a receiving bin 6 located below the carrying platform 5 that supplies materials for each processing unit 7 respectively. The carrying platform 5 has a horizontal guide rail 5a, and the distribution vehicle 4 includes a vehicle frame 4b with rollers 4a at the bottom, an automatic weighing device 4c arranged on the vehicle frame, a box-type hopper 4d placed on the weighing device, There is an outlet 4e at the bottom of the box-type hopper, and an automatic valve 4f arranged below the outlet; the distributing vehicle 4 reciprocates through the roller 4a placed on the horizontal guide rail 5a. An automatic valve 4f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com