Automatic weighing and grouping equipment for production of PVB rubber powder

An automatic weighing and rubber powder technology, which is applied in the direction of solid materials, packaging, and packaging item types, can solve the problems of affecting work efficiency, lack of automatic weighing and grouping of PVB rubber powder, and waste of manpower, so as to improve work efficiency and promote Industrial development and the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

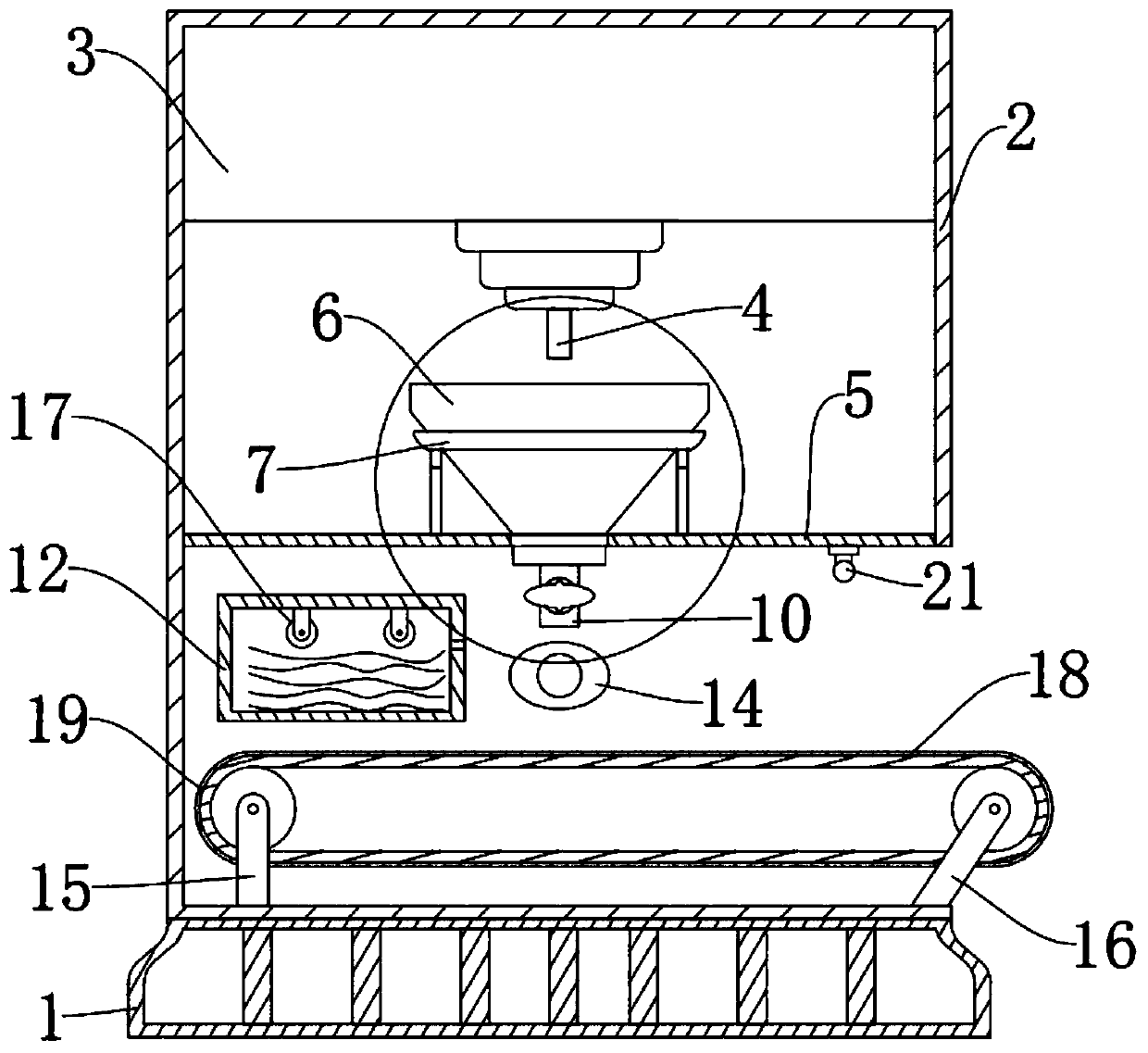

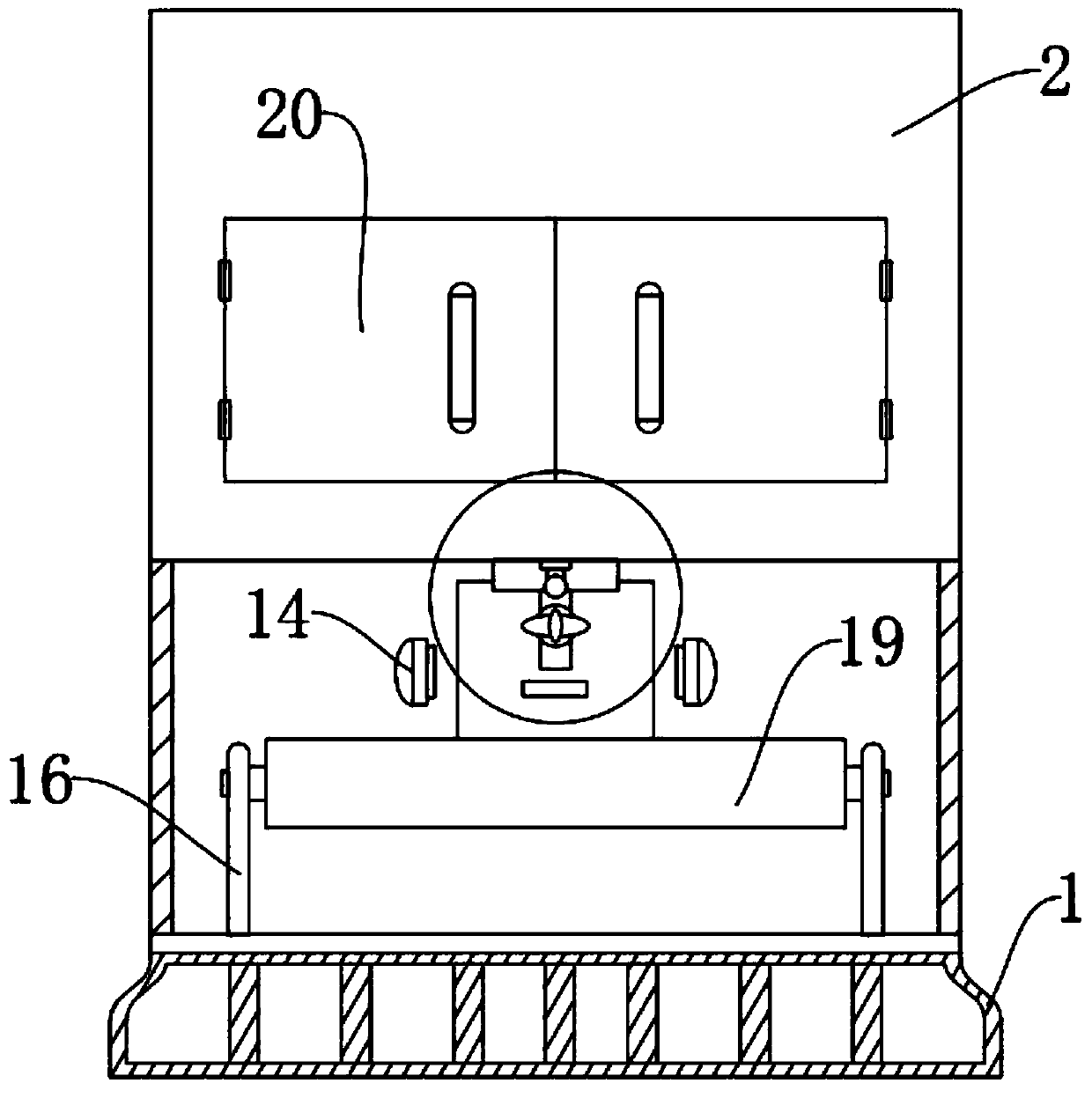

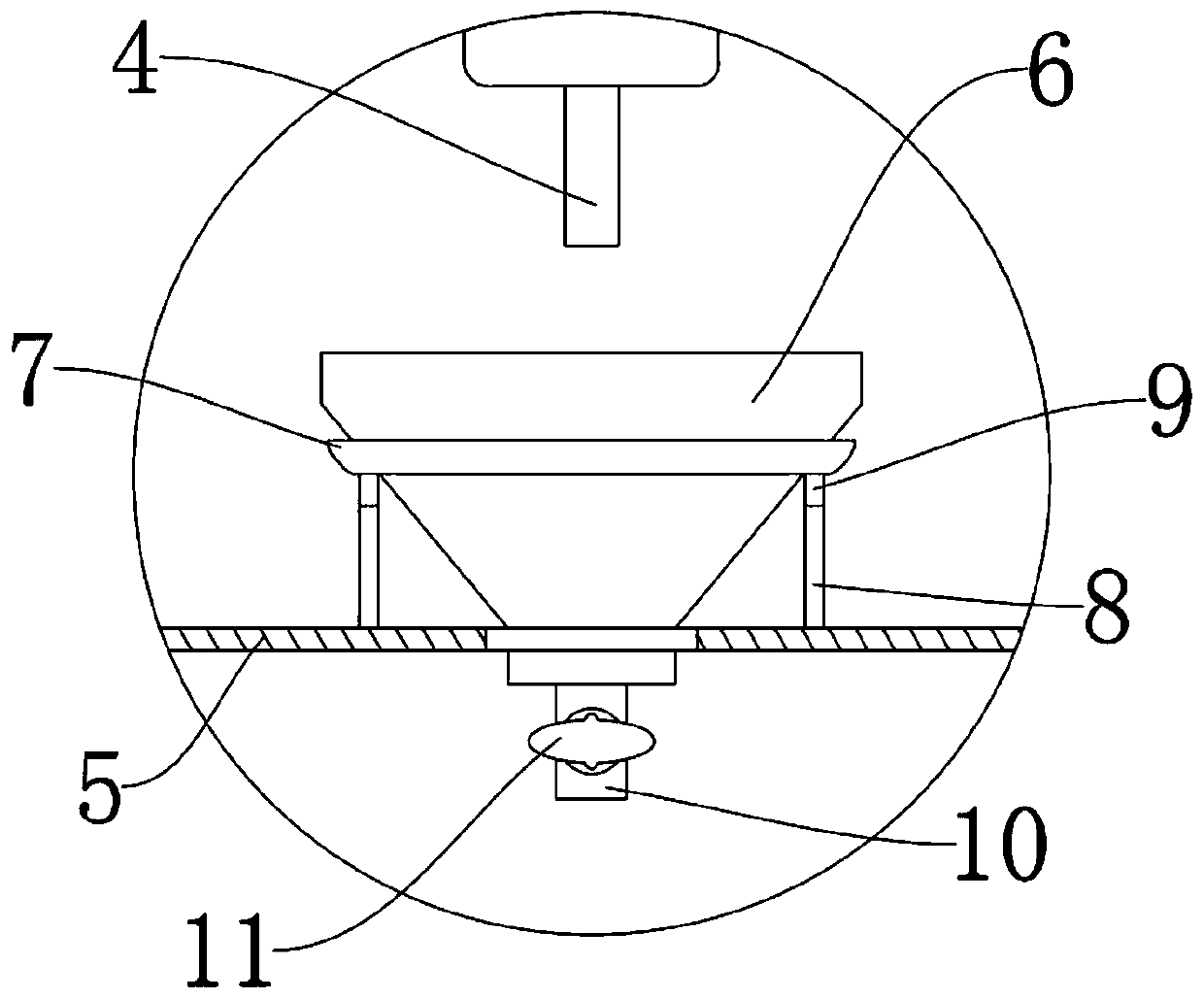

[0034] Example: such as figure 1As shown, the equipment includes a base 1, a chassis 2, a production component 3 and a discharge port 4, the chassis 2 is installed on the upper wall of the base 1, the production component 3 is installed on the lower wall of the chassis 2, and the discharge port 4 is installed vertically On the production component 3; the device is equipped with a weighing structure mainly including: a mounting plate 5, a conical box 6 and a weighing part; the mounting plate 5 is installed on the left and right opposite walls of the chassis 2, and the conical box 6 is inserted into on the board 5; wherein, the weighing part mainly includes: a ferrule 7, a pair of fixed rods 8 with the same structure, a pair of pressure sensors 9 with the same structure, and a weighing assembly; the ferrule 7 is set on the conical box 6, and a The fixed rods 8 are installed on the upper wall of the mounting plate 5 and located on both sides of the conical box 6, and a pair of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com