System for treating household garbage leachate

A landfill leachate and treatment system technology, applied in the field of environmental protection, can solve problems such as high operating costs, difficult treatment, and large equipment investment, and achieve the effects of reducing operating costs, reducing equipment investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

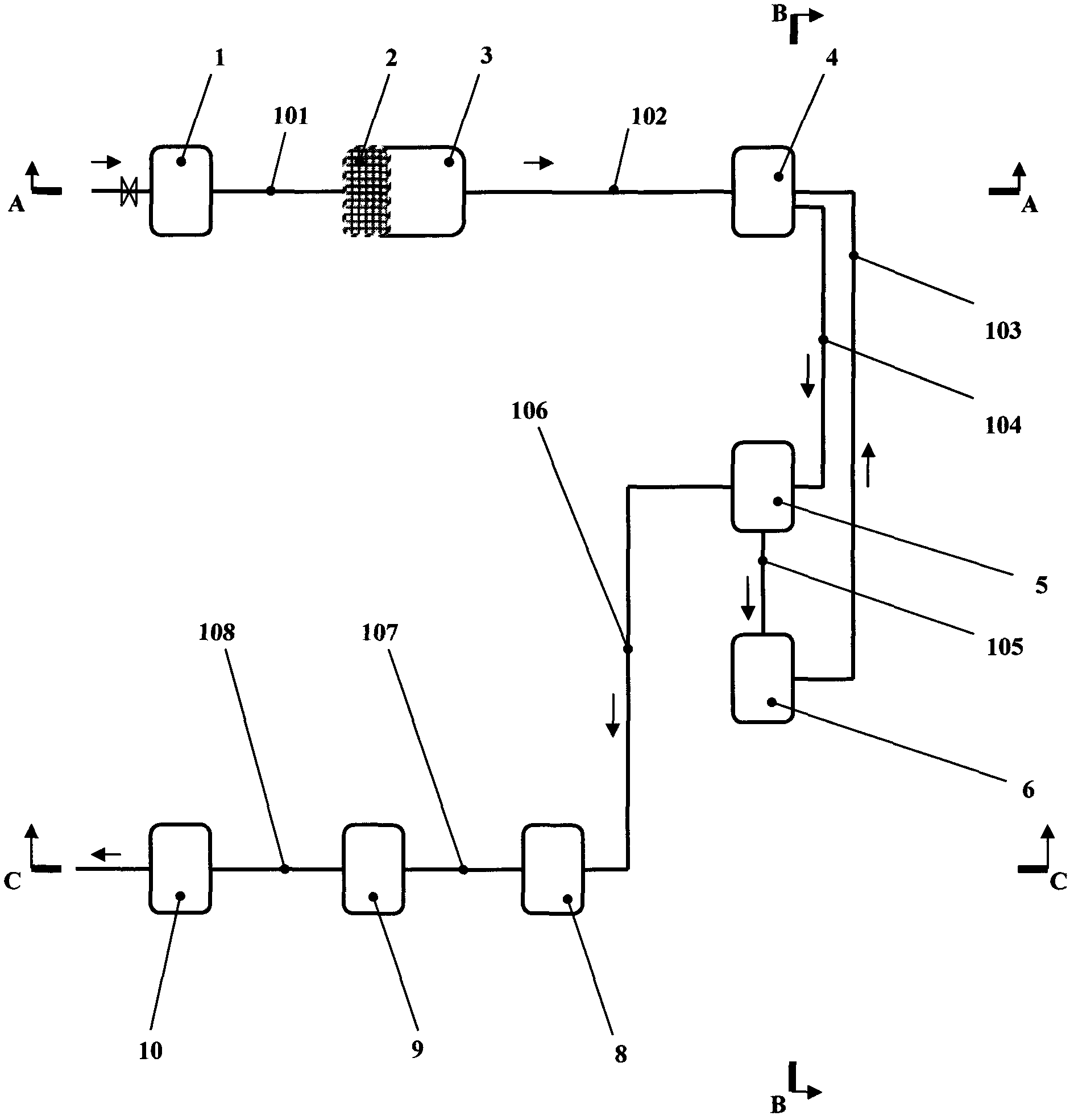

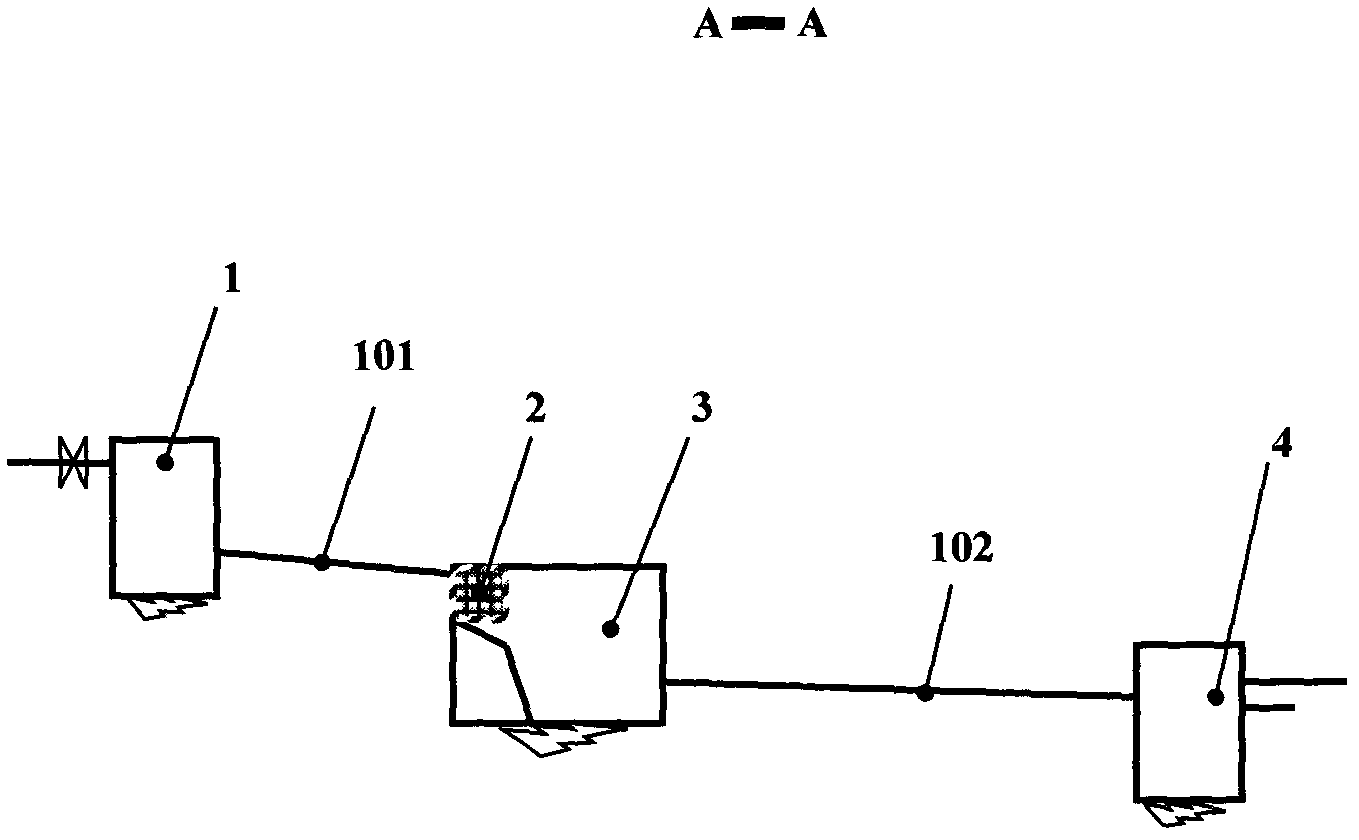

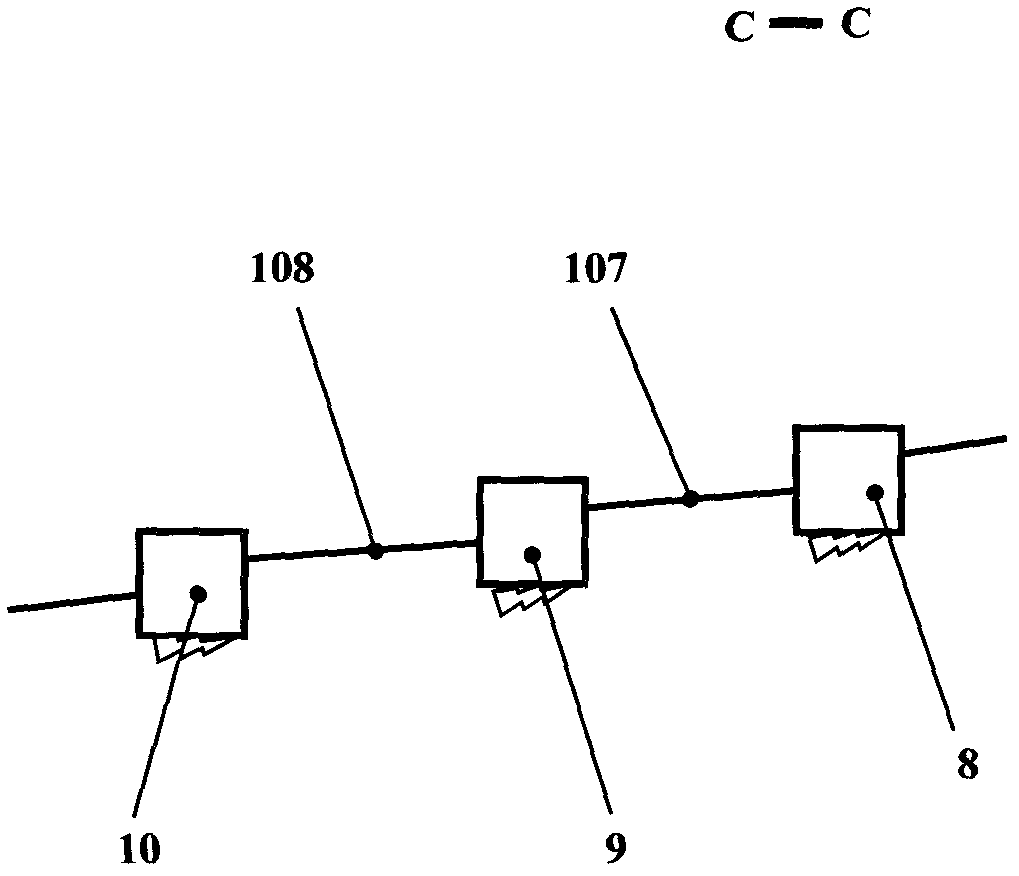

[0054] exist figure 1 figure 2 image 3 Figure 4 In the first embodiment shown, a domestic waste leachate treatment system includes a landfill leachate pool 1, a grid 2, an aeration pool 4, a sedimentation pool 5, a sludge pool 6, a filter pool 8, reverse osmosis Membrane treatment tank 9, clean water tank 10, the liquid discharge outlet of landfill leachate tank 1 and the liquid inlet of grille 2 are connected with pipeline 101, the liquid outlet of aeration tank 4 is connected with the liquid inlet of sedimentation tank 5 Connect with pipeline 104 between, connect with pipeline 105 between the sludge outlet of sedimentation tank 5 and the sludge inflow inlet of sludge tank 6, use pipeline between the liquid outlet of sedimentation tank 5 and the liquid inflow inlet of filter tank 8 106 is connected, and the liquid outlet of filter pool 8 is connected with the liquid inlet of reverse osmosis membrane treatment pool 9 with pipeline 107, and the liquid outlet of reverse os...

Embodiment 2

[0080] exist Figure 5 Figure 6 Figure 7 Figure 8 In the second embodiment shown, a domestic waste leachate treatment system includes a landfill leachate tank 1, a grille 2, an aeration tank 4, a sedimentation tank 5, a sludge tank 6, a filter tank 8, a reverse osmosis Membrane treatment tank 9, clear water tank 10, the liquid discharge outlet of landfill leachate tank 1 and the liquid inlet of grille 2 are connected with pipeline 101, the liquid outlet of aeration tank 4 and the liquid inlet of sedimentation tank 5 are connected Connect with pipeline 104 between, connect with pipeline 105 between the sludge outlet of sedimentation tank 5 and the sludge inlet of sludge tank 6, use pipeline between the liquid outlet of sedimentation tank 5 and the liquid inlet of filter tank 8 106 is connected, and the liquid outlet of filter pool 8 is connected with the liquid inlet of reverse osmosis membrane treatment pool 9 with pipeline 107, and the liquid outlet of reverse osmosis m...

Embodiment 3

[0107] exist Figure 9 Figure 6 Figure 10 Figure 11 In the third embodiment shown, a domestic waste leachate treatment system includes a landfill leachate pool 1, a grid 2, an aeration pool 4, a sedimentation pool 5 and 7, a sludge pool 6, a filter pool 8, The reverse osmosis membrane treatment tank 9, the clean water tank 10, the liquid discharge port of the landfill leachate tank 1 and the liquid inflow port of the grille 2 are connected with a pipeline 101, and the liquid discharge port of the aeration tank 4 is connected with the liquid flow port of the sedimentation tank 5. The inlets are connected with pipeline 104, the sludge outlet of sedimentation tank 5 is connected with the sludge inlet of sludge tank 6 with pipeline 105, and the liquid outlet of sedimentation tank 5 is connected with the liquid inlet of filter tank 8. Connect with pipeline 106, connect with pipeline 109 between the liquid outlet of aeration tank 4 and the liquid inlet of sedimentation tank 7,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap