Non-contact power-supplying type wireless electric iron and ironing board used for non-contact power supplying

A technology of non-contact power supply and cordless electric iron, applied in ironing boards, hand irons, applications, etc., can solve the problems of poor convenience of use of electric irons, electric iron leakage, etc., achieve flexible activities, prevent electric leakage accidents, and improve use convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

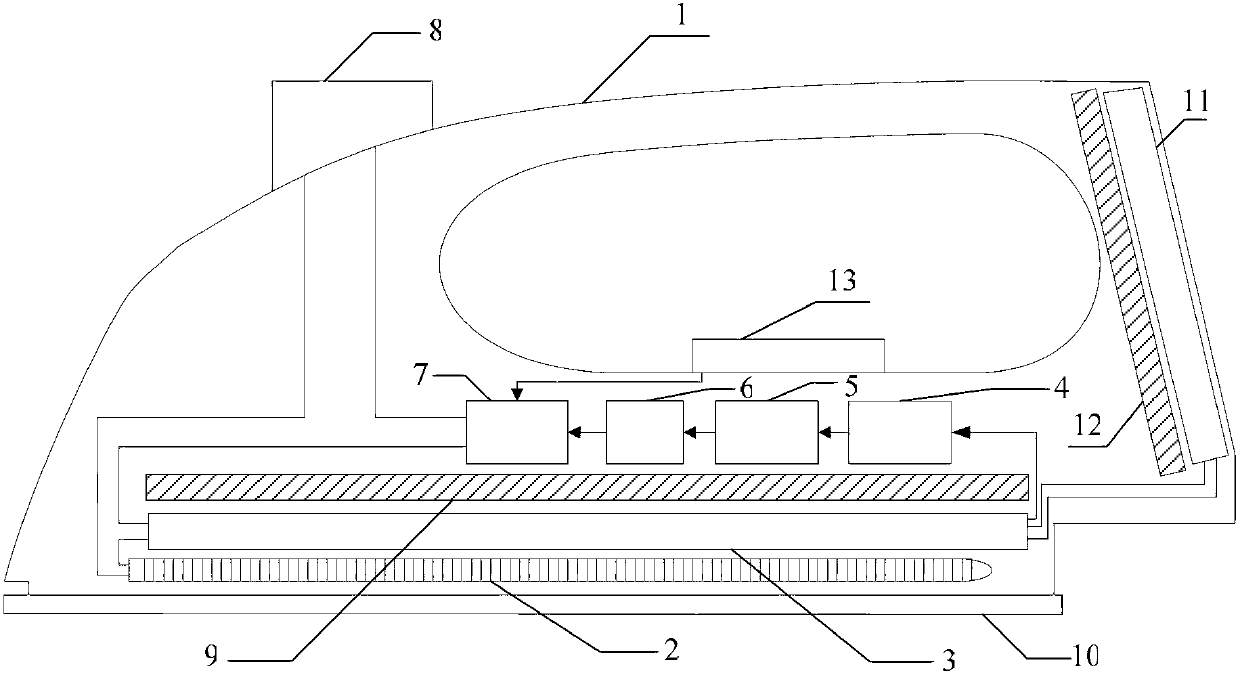

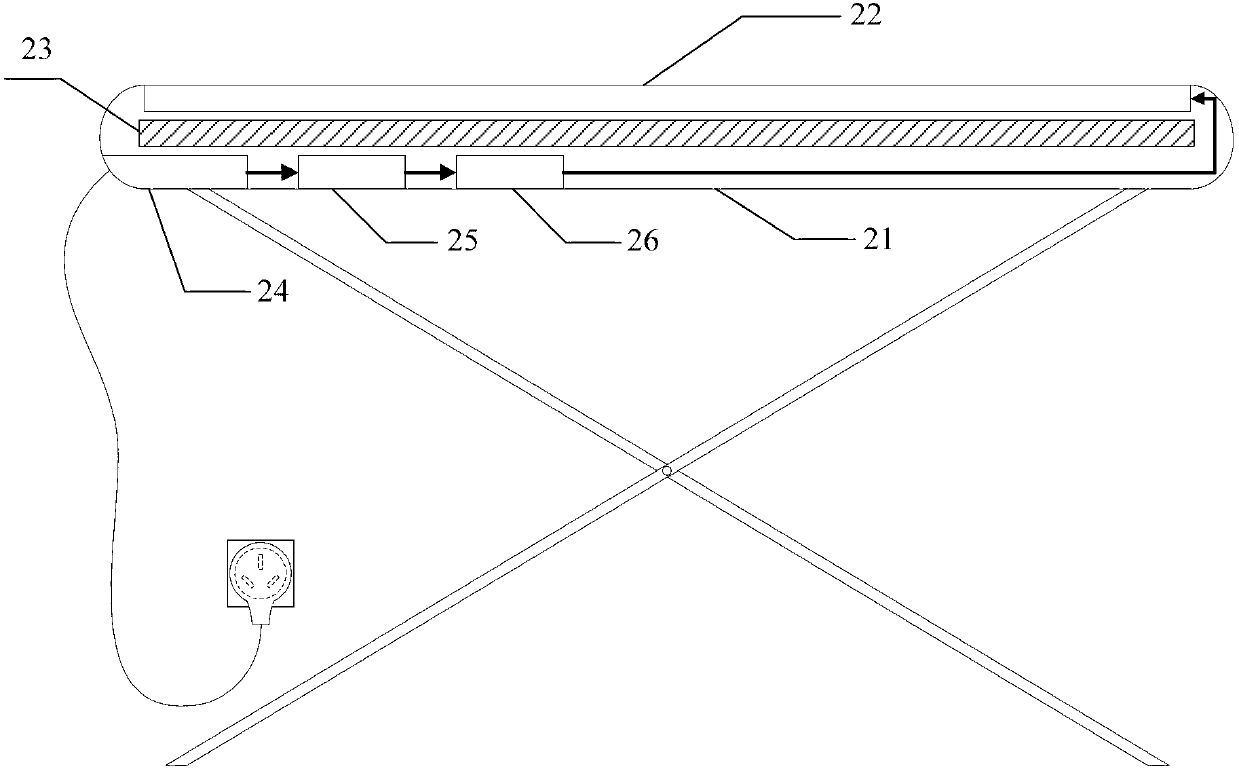

[0021] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, a non-contact power supply type cordless electric iron, which includes an electric iron body 1, an electric heater 2 and a heating switch 8, the electric heater is located inside the electric iron body 1 and is fixed in the electric iron body 1 The upper surface of the high temperature resistant non-metal base plate 10; the heating switch 8 is arranged on the electric iron body 1;

[0022] It also includes No. 1 energy receiving circuit 3, No. 1 shielding layer 9, high-frequency transformer 4, No. 1 rectification circuit 5, voltage stabilizing circuit 6 and iron control circuit 7;

[0023] No. 1 energy receiving circuit 3, shielding layer 9, high-frequency transformer 4, No. 1 rectifier circuit 5, voltage stabilizing circuit 6 and iron control circuit 7 are all fixed inside the electric iron body 1, and No. 1 energy receiving circuit 3 is set in the durable Above the high-temperatur...

specific Embodiment approach 2

[0026] Embodiment 2. The difference between this embodiment and the non-contact power supply type cordless electric iron described in Embodiment 1 is that it also includes a No. 2 energy receiving circuit 11 and a No. 2 shielding layer 12;

[0027] The No. 2 energy receiving circuit 11 is located inside the electric iron body 1 and is arranged on the tail supporting surface of the electric iron body 1; the No. 2 shielding layer 12 is arranged on the left side of the No. 2 energy receiving circuit 11;

[0028] The No. 2 energy receiving circuit 11 is connected in parallel with the No. 1 energy receiving circuit 3 .

[0029] In this embodiment, the No. 1 energy receiving circuit and the No. 2 energy receiving circuit of the electric iron body 1 receive the alternating magnetic field and convert it into an alternating current with frequency f. On the one hand, it directly supplies power to the electric heater; 1. No. 1 rectifier circuit and voltage stabilizing circuit supply powe...

specific Embodiment approach 3

[0032] Embodiment 3. The difference between this embodiment and the non-contact power supply type cordless electric iron described in Embodiment 1 or 2 is that it also includes a temperature adjustment knob 13 which is arranged on the body 1 of the electric iron ; The temperature adjustment control signal output end of the temperature knob 13 is connected to the temperature adjustment signal input end of the iron control circuit 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com