Vehicle-mounted main drive battery box airtightness detecting equipment

A main drive battery, air tightness detection technology, used in the use of liquid/vacuum degree for liquid tightness measurement, by measuring the fluid's acceleration and deceleration rate, etc., can solve the problems of water vapor corrosion, large volume, etc., to achieve non-conductive liquid, Simple effect of electrical control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

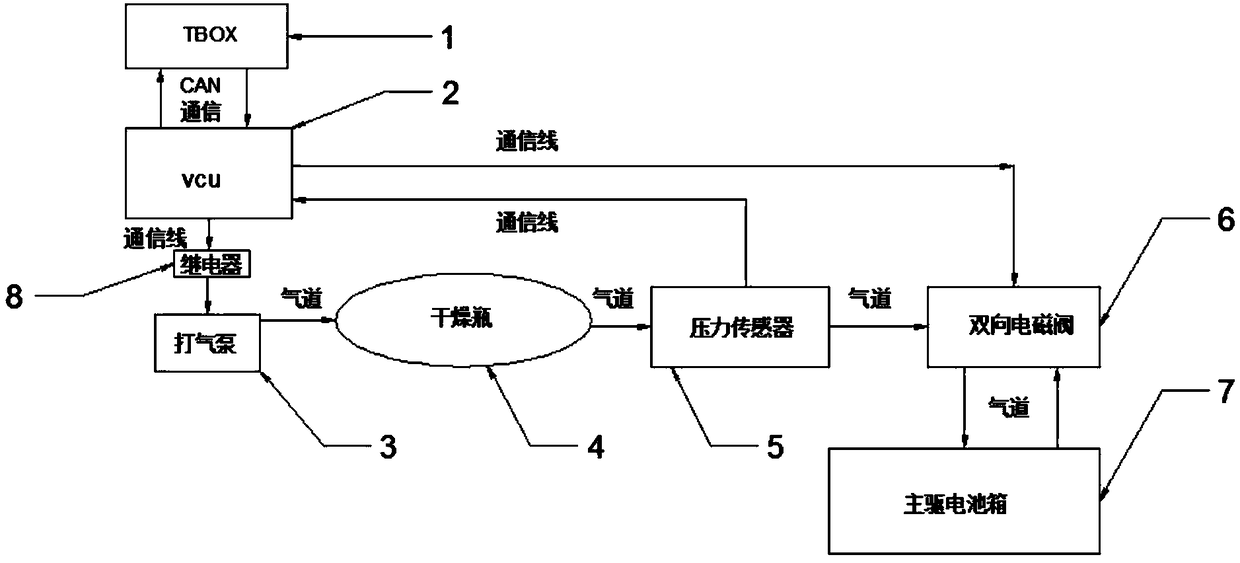

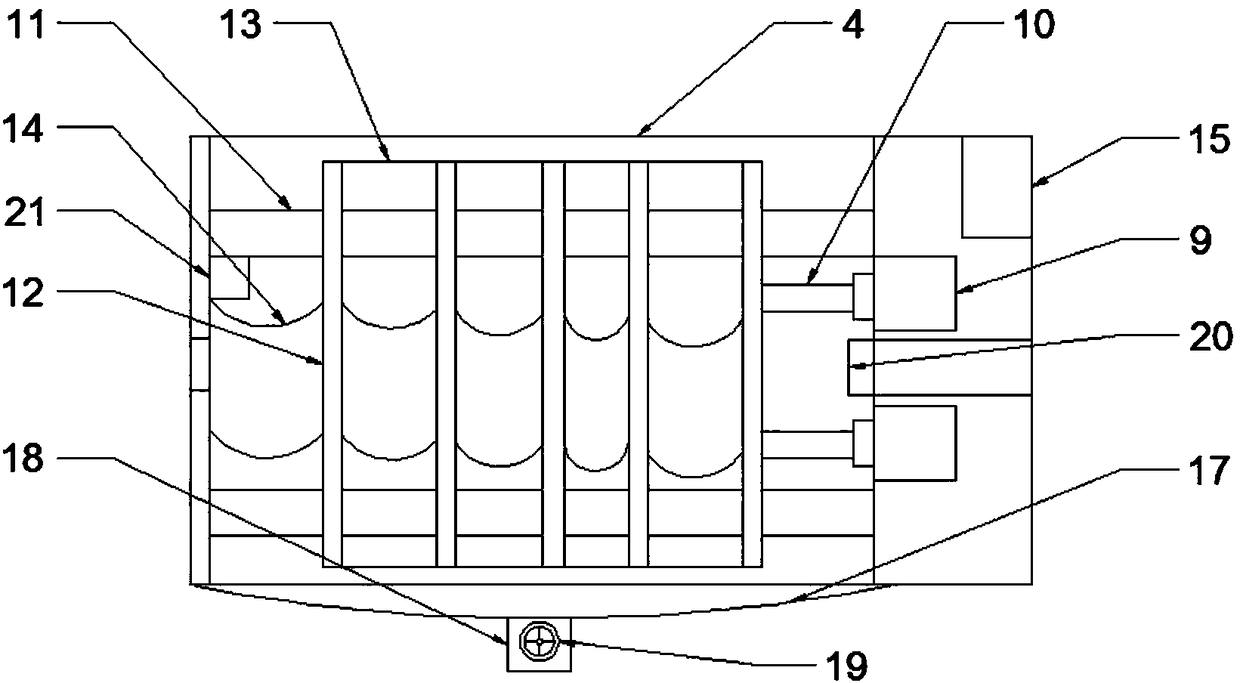

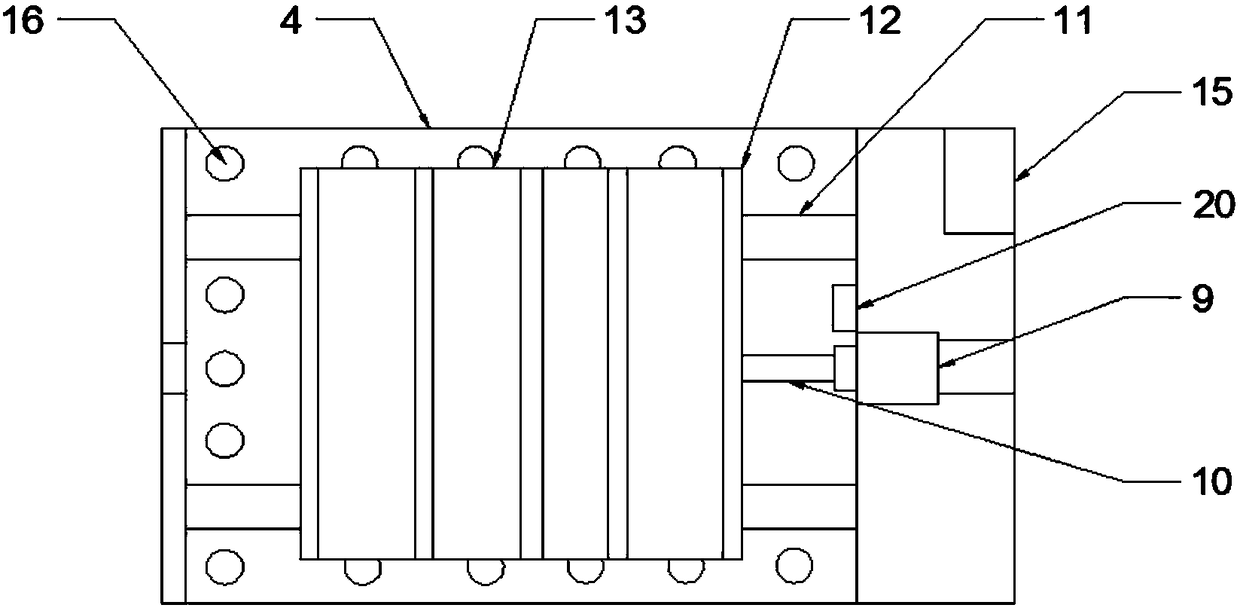

[0014] combined with figure 1 , a vehicle-mounted main drive battery box airtight detection equipment, including a vehicle network interconnection terminal TBOX1, a vehicle controller VCU2, an air pump 3, a dry bottle 4, a pressure sensor 5, a two-way solenoid valve 6, and a main drive battery box 7 , relay 8, the vehicle network interconnection terminal TBOX1 is bidirectionally connected to the vehicle controller VCU2 through the CAN communication line, and the vehicle controller VCU2 is unidirectionally connected to the bidirectional solenoid valve 6 with I / O signals through the communication line, so The above pressure sensor 5 communicates with the vehicle controller VCU2 in one direction with an analog signal through the communication line, and the vehicle controller VCU2 controls the relay 8 with an I / O signal through the communication line, and the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com