Precast concrete component butting structure and butting method thereof

A prefabricated component and concrete technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as the inability to achieve anti-corrosion effect, and achieve the effects of improving anti-corrosion, fast construction, and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

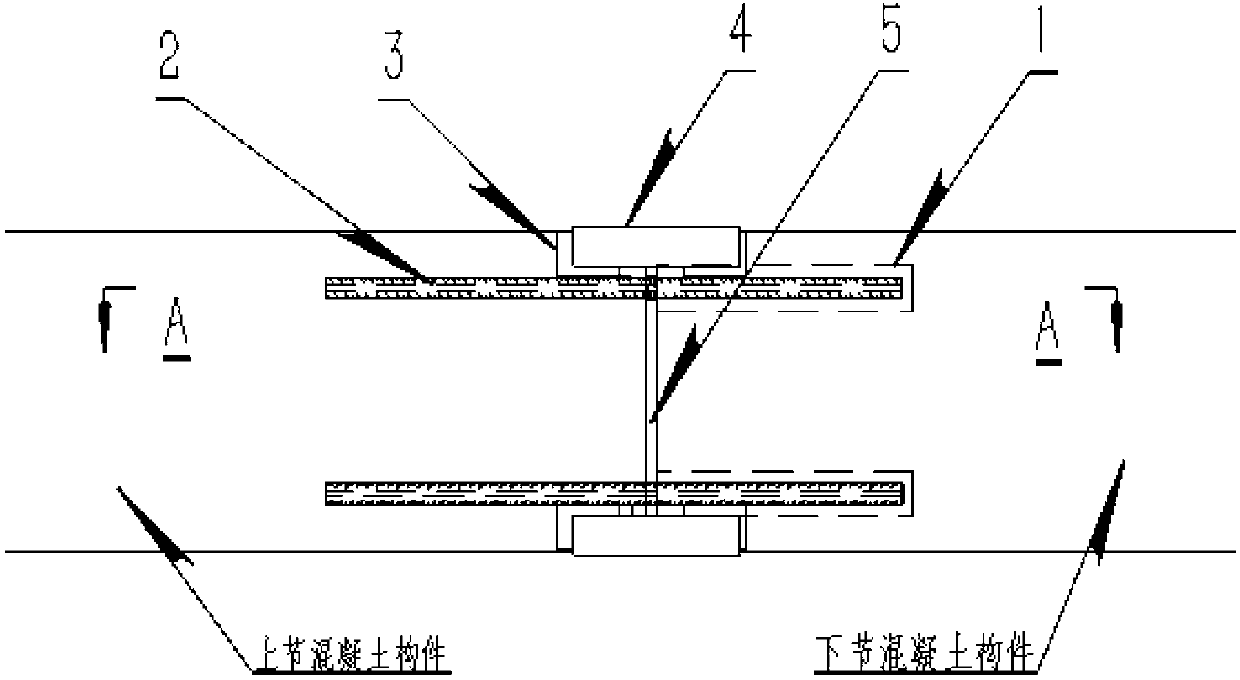

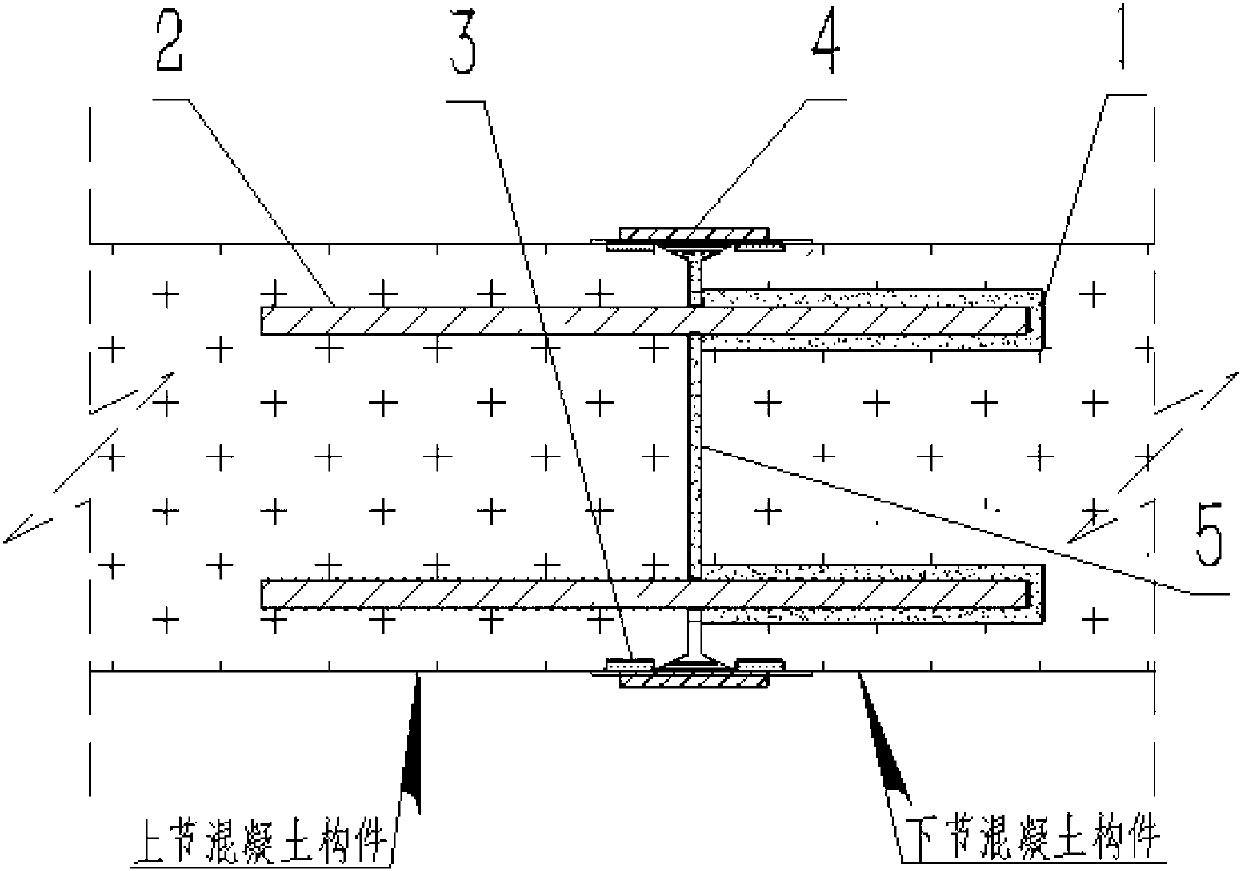

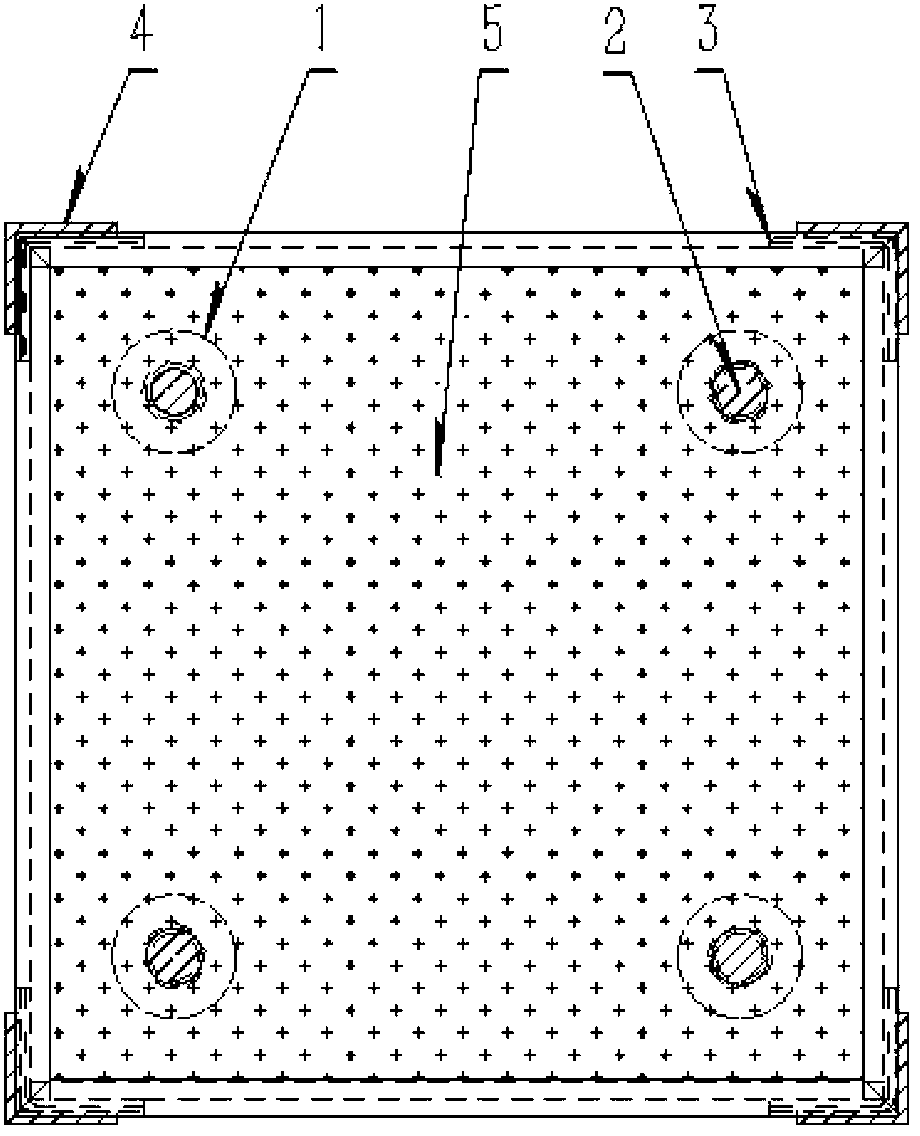

[0035] like figure 1 , figure 2 and image 3 Shown:

[0036] A butt joint structure of prefabricated concrete components, which is mainly used for the connection of prefabricated concrete components of underground foundations; to butt prefabricated concrete components, a butt end is predetermined first; the upper end surface of the lower section of the prefabricated concrete component to be connected is used as the butt joint end, preset Reservation hole 1 for inserting reinforcement; the lower end surface of the upper section member to be docked with the concrete prefabricated component is used as its butt joint end, and the insertion anchor reinforcement 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com