Clamping and unscrewing device for iron driller

An iron driller and clamping technology, which is applied in the field of iron driller clamping and unscrewing devices, can solve the problems of complex structure, unstable floating and rotation, and large damage to drill pipes, and achieves good interchangeability and unscrewing movement. Independent, less damage to drill pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

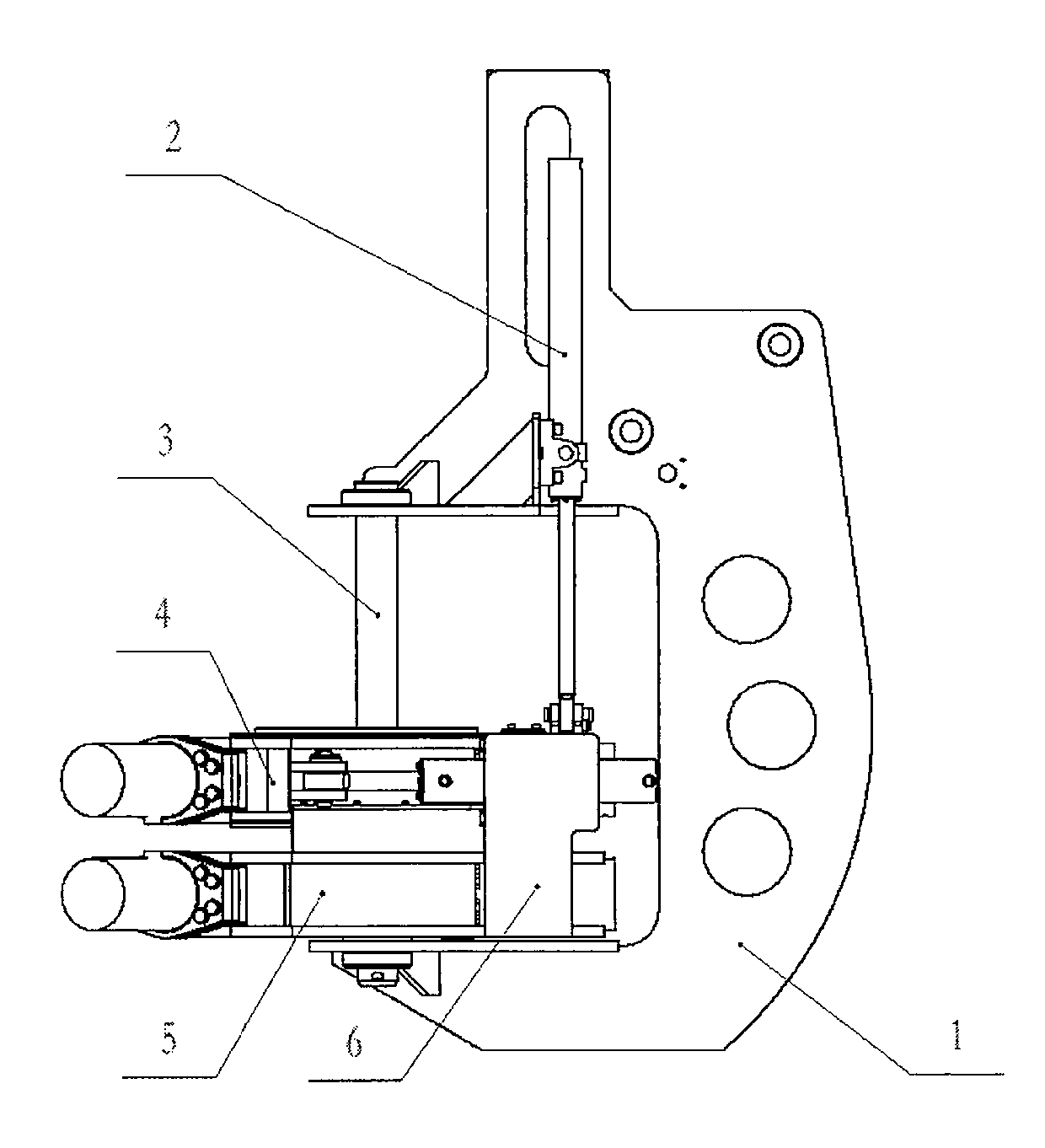

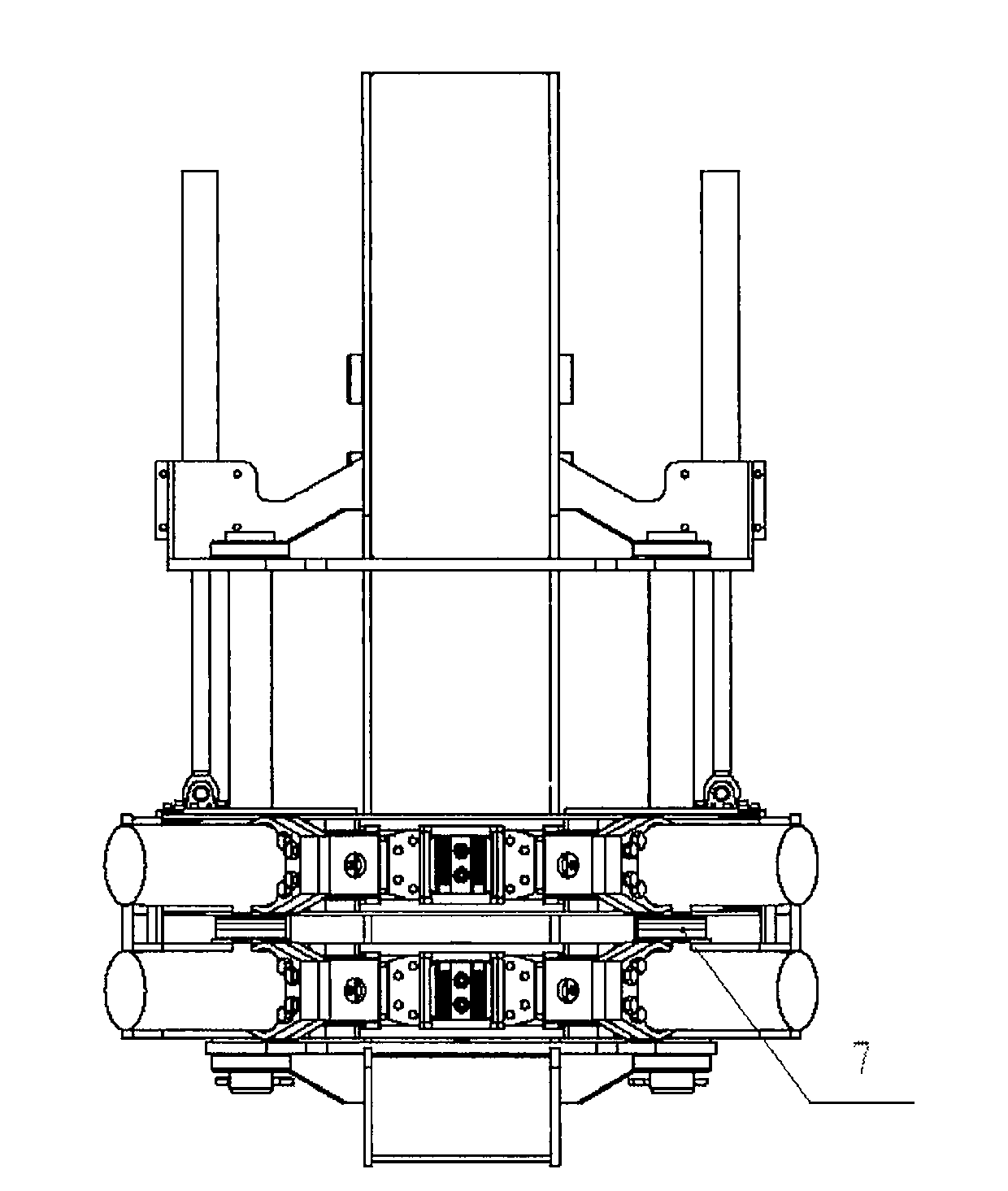

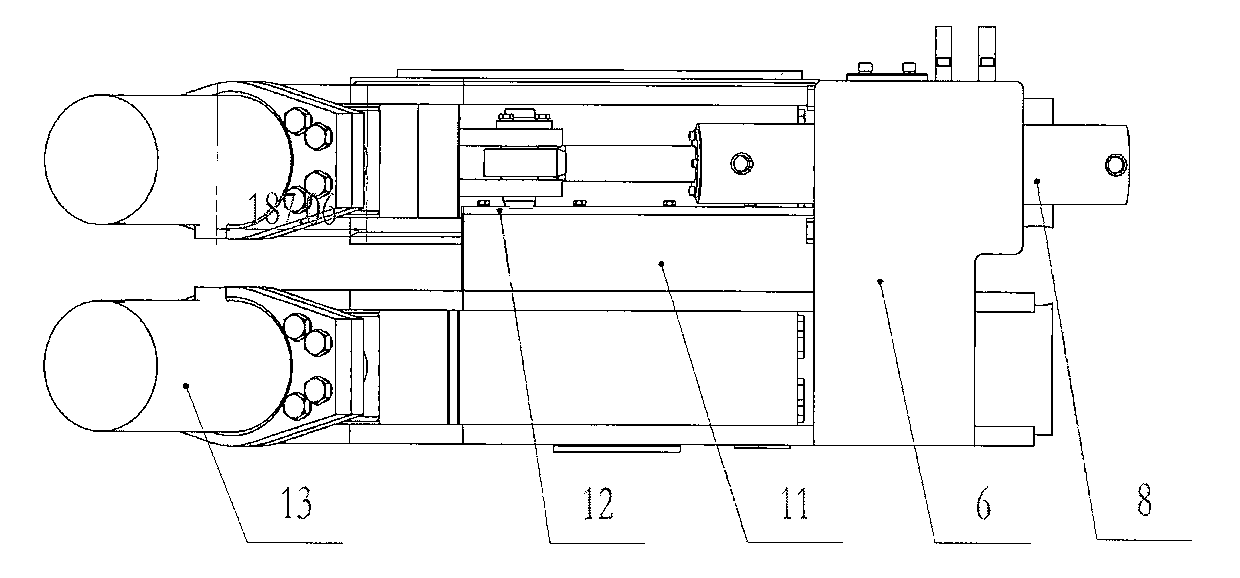

[0022] see Figure 1 to Figure 7 As shown, the present embodiment is made up of support 1, lifting cylinder 2, vertical pin 3, shackle pliers mechanism 4, clamping pliers mechanism 5, tong box 6 and stack spring 7; wherein, support 1 and end hinge shaft type The lifting cylinder 2 is hinged, the piston rod of the lifting cylinder 2 is hinged with the clamp box 6, and the lifting cylinder 2 is symmetrically arranged; the clamp box 6 is fixedly connected with the clamping pliers mechanism 5, so that the pliers body moves with the lifting cylinder; the shackle clamp mechanism 4 and A stack spring 7 is installed between the clamping pliers mechanism 5 to ensure that the shackle pliers float smoothly when the drill pipe is unscrewed; the vertical pin 3 passes through the shackle pliers mechanism 4 and the clamping pliers mechanism 5, The two ends are fixedly connected with the bracket 1, and can play a guiding role when lifting and unscrewing the drill pipe.

[0023] The symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com