Underground coal seam hydrofracture crack oriented developing method

A hydraulic fracturing and fracturing technology, which is applied in the field of high-efficiency hydraulic fracturing for enhanced gas drainage in coal mines, can solve the problems of large drilling workload, failure to consider the expansion and closure of cracks, and failure to consider the expansion and closure of cracks. , to achieve the effects of controlling gas disasters, reducing crack initiation pressure, and strengthening gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

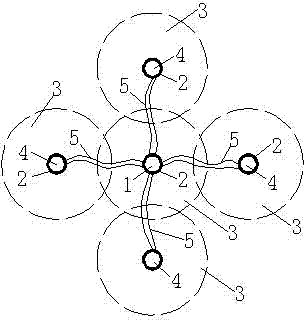

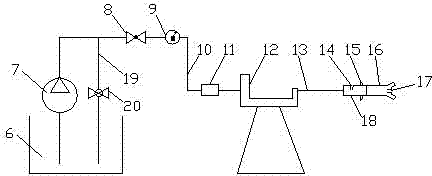

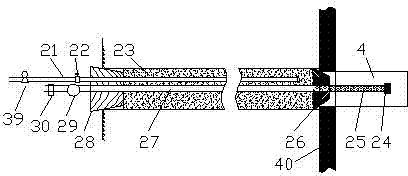

[0022] Depend on Figure 1-Figure 4 A method for guided expansion of hydraulic fracturing fractures in an underground coal seam includes the following steps:

[0023] (1) Drilling the fracturing borehole 1 and the pilot borehole 4. The fracturing borehole 1 is one, the pilot borehole 4 is several, and the pilot borehole 4 is set at intervals around the fracturing borehole 1. Drill hole 1 and each pilot hole 4 are respectively subjected to radial water jet slits. Water jet slits are realized by high-pressure water jet slit devices. When water jet slits: first determine the water jet slit depth Rs:

[0024]

[0025] In the above formula, R s is the water jet slotting depth (in mm), C f is the kinetic friction coefficient of water, d is the nozzle diameter of the high-pressure water jet slotting device (in mm), is the compressive strength of coal (in MPa), P is the nozzle outlet pressure (MPa) of the high-pressure water jet slotting device, is the damping coeffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com