Method for controlling gap between blade tip of turbine casing and blade tip of turbine rotor blade

A technology of turbine casing and turbine rotor, used in mechanical equipment, engine components, machines/engines, etc., to solve problems such as heavy weight and thrust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

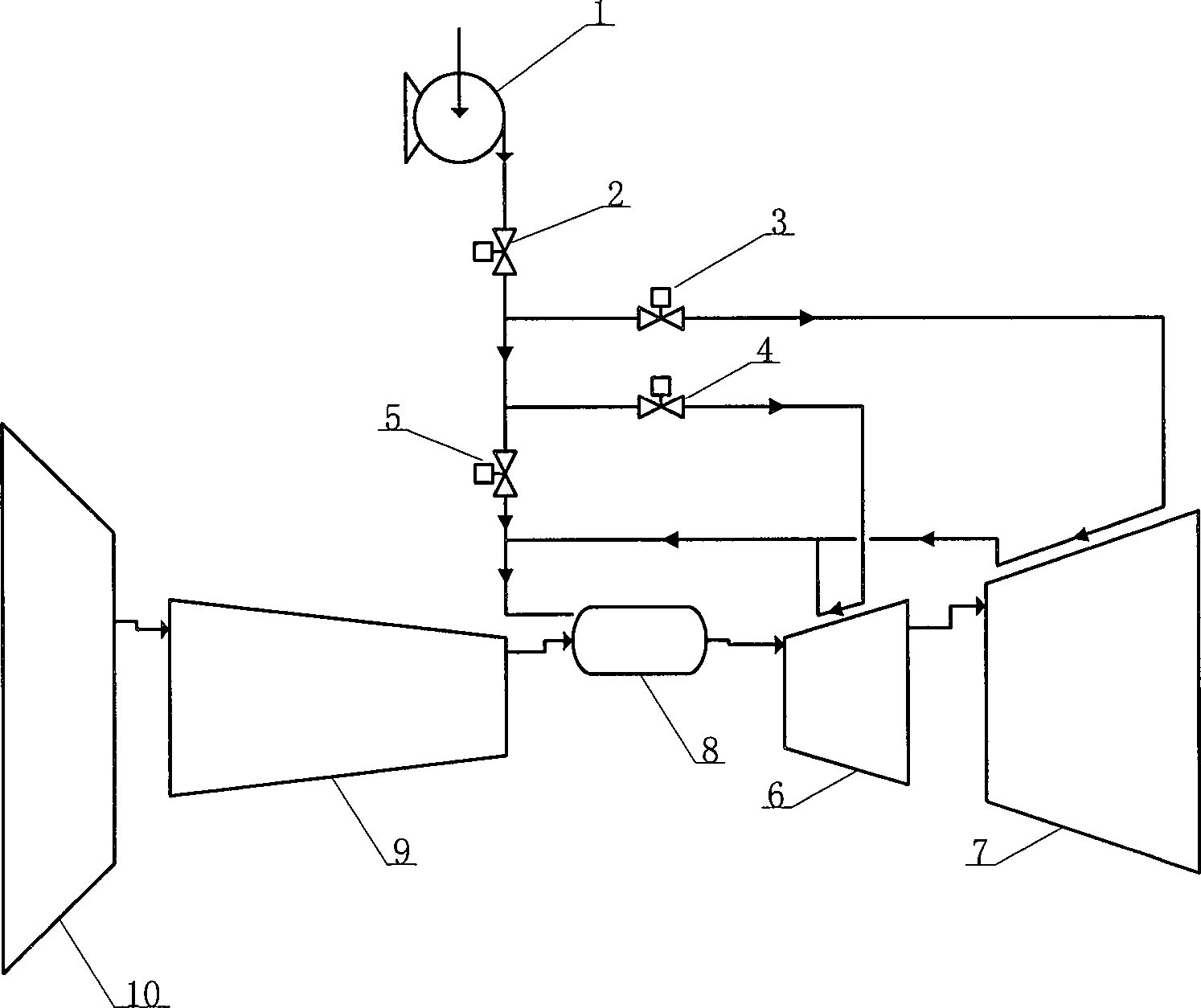

[0028] Such as figure 1 As shown, it schematically shows a clearance control system of a gas turbine engine according to an embodiment of the present invention. The gas turbine engine has a fan 10, a low-pressure compressor (not shown), a high-pressure compressor 9, a combustion chamber 8, a high-pressure turbine 6 and a low-pressure turbine 7, etc. in the airflow direction, wherein the low-pressure compressor and the low-pressure turbine 7 are connected to On one shaft, the high pressure compressor 9 and the high pressure turbine 6 are connected to the other shaft. In addition, in the circumferential and axial directions, all the above-mentioned engine components are surrounded by segmented casings, for example, the high-pressure turbine rotor 6 and the low-pressure turbine rotor 7 are respectively surrounded by high-pressure turbine casings and low-pressure turbine casings. Wherein, the high-pressure turbine casing and the low-pressure turbine casing are casings with annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com