Heat Pipe Solar Collector and Its Sealing Structure

A solar heat collector and sealing structure technology, applied in the field of solar heat collectors, can solve problems such as leakage of welding joints, complex and time-consuming assembly methods of heat pipe type solar heat collector 1a, discounted heat conduction efficiency, etc., to prevent leakage , Increase practicality, good heat collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The detailed description and technical content of the present invention are described below in conjunction with the accompanying drawings. However, the accompanying drawings are only for reference and description, and are not intended to limit the present invention.

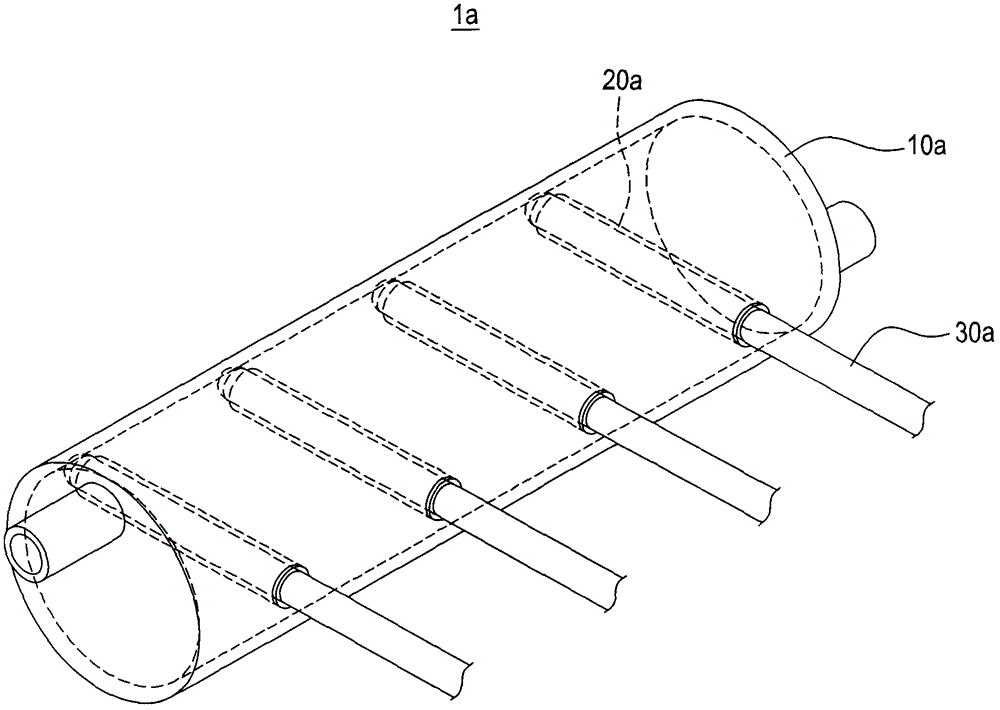

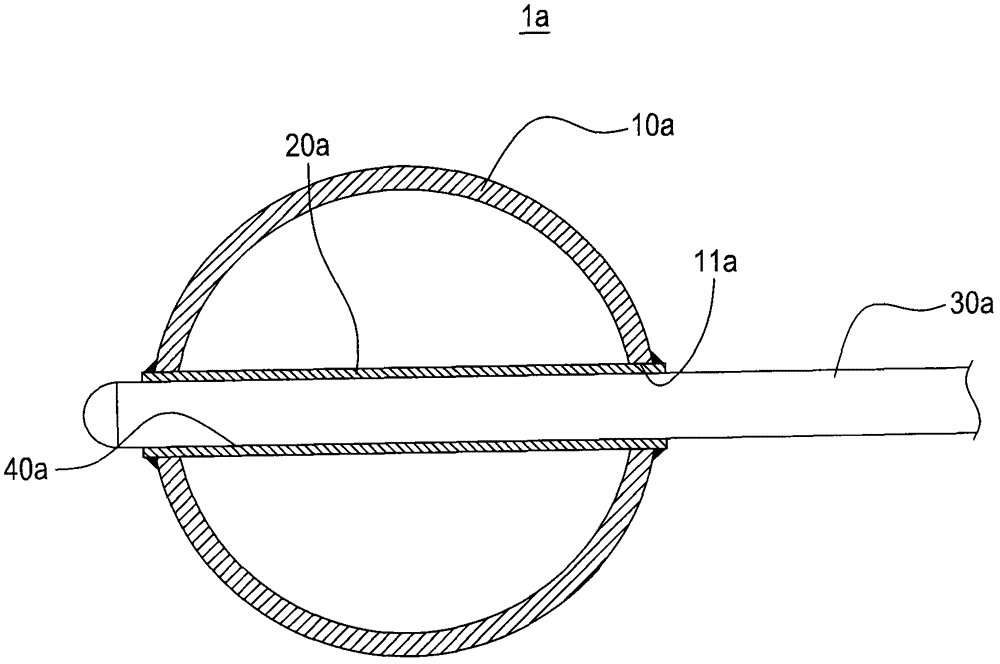

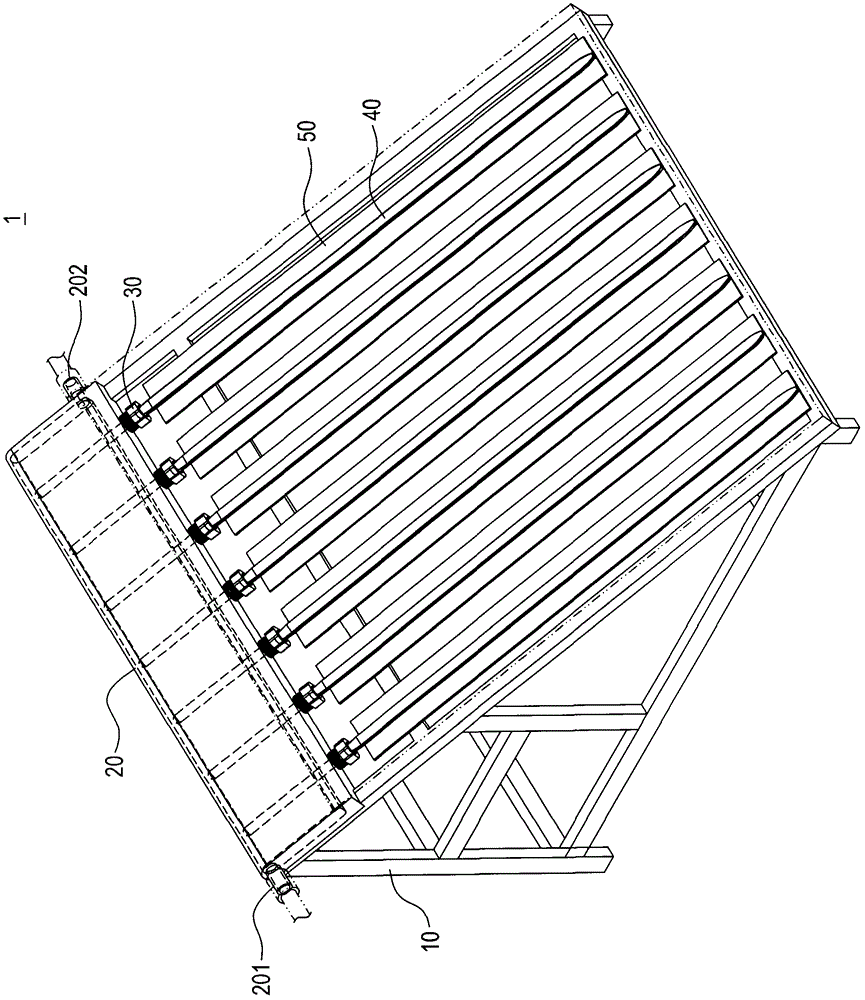

[0062] Please refer to image 3 , is a schematic diagram of the use of the heat pipe solar collector of the present invention; the heat pipe solar collector 1 (hereinafter referred to as the collector) of the present invention includes a heat collecting frame 10 , a heat exchange pipe body 20 , and a sealing structure 30 , at least one heat pipe 40 , and at least one heat collecting plate 50 .

[0063] In this embodiment, the heat collecting frame 10 is a triangular frame body, but not limited to this, the heat exchange tube body 20 and the heat pipe 40 are fixed on the heat collecting frame 10, and the heat exchange tube body The heat pipe 40 is embedded on the heat collecting plate 50 , and the heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com