Cable bridge frame cover plate

A technology for cable trays and cover plates, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as unfavorable cable laying, unsightly appearance, and affecting construction, and achieves benefits for cable laying construction and shape design. Novelty, the effect of increasing the effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

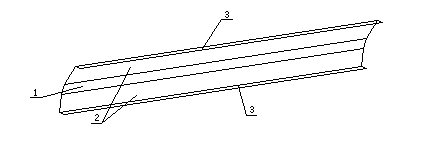

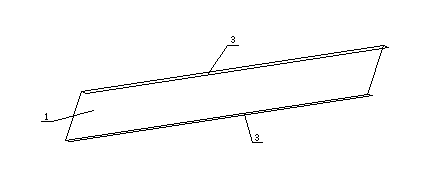

[0011] The present invention includes a cover top surface arranged in a certain radian and a cover vertical surface 3 arranged on both sides of the cover top surface; the cover top surface of the present invention includes a cover plane 1 and a cover plane 1 and a cover plate Between the vertical surfaces 3 is the cover plate slope 2 that connects the cover plate plane 1 and the cover plate vertical surface 3 and is arranged obliquely downward.

[0012] The cover plate slope 2 of the present invention is arranged symmetrically.

[0013] The present invention is especially suitable for long-distance laying of cables, and when large-diameter cables are bent and laid, or when there are many cables in the bridge frame, the advantages of the present invention will be more prominent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com