Rotary type internally-flowing particle material drying machine

A technology for granular materials and dryers, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of mutual pollution between materials and the environment, high labor intensity of workers, and unfavorable large-scale production, and achieve savings. Manpower, small footprint, and the effect of preventing cross pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

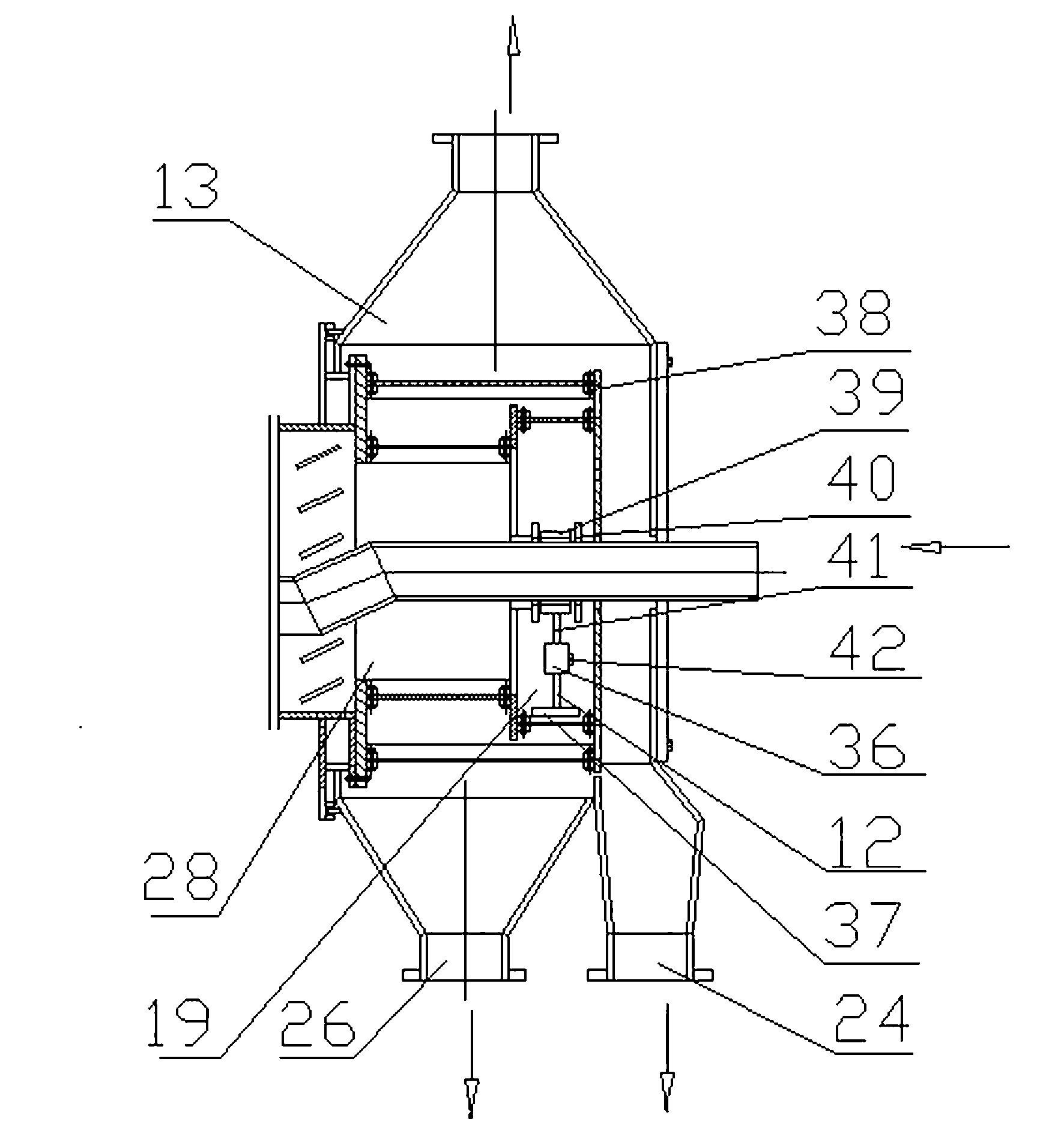

[0082] There are four jet nozzles on the air inlet main pipe 20, and the diameter of the jet nozzles is 40mm.

[0083] The acute angle between the spouts is 45 degrees. The four jet nozzles are symmetrically located on both sides of the diameter of the air inlet main pipe 20 perpendicular to the horizontal plane.

[0084] The air outlet speed of the jet nozzle is determined according to the parameters such as the humidity of the material, the required drying temperature and the number of jet nozzles, the moisture content of the product and the humidity of the material, the required drying temperature, the length of the air inlet main pipe 20, the nozzle The number of nozzles, the air outlet speed of jet nozzles and other factors are related, and this is a known technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com