Circuit and method for regulating detecting end resonant frequency of capacitor type micro-electromechanical systems (MEMS) gyroscope

A technology of resonant frequency and detection terminal, which is applied in the field of MEMS and circuits, can solve the problems of reducing the detection sensitivity, the resonant frequency of the detection terminal and the frequency of the driving terminal are inconsistent, and achieve the effect of correcting the mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

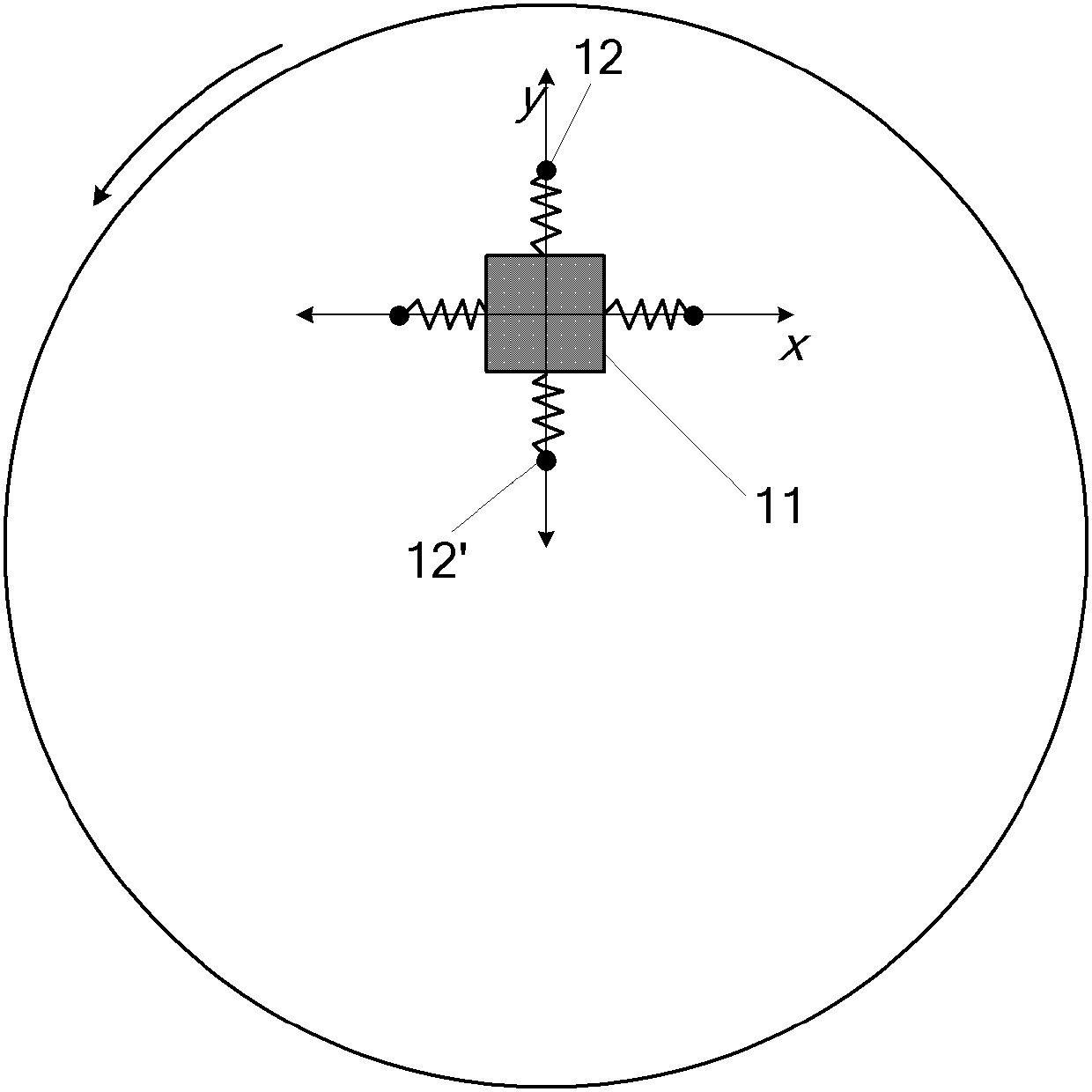

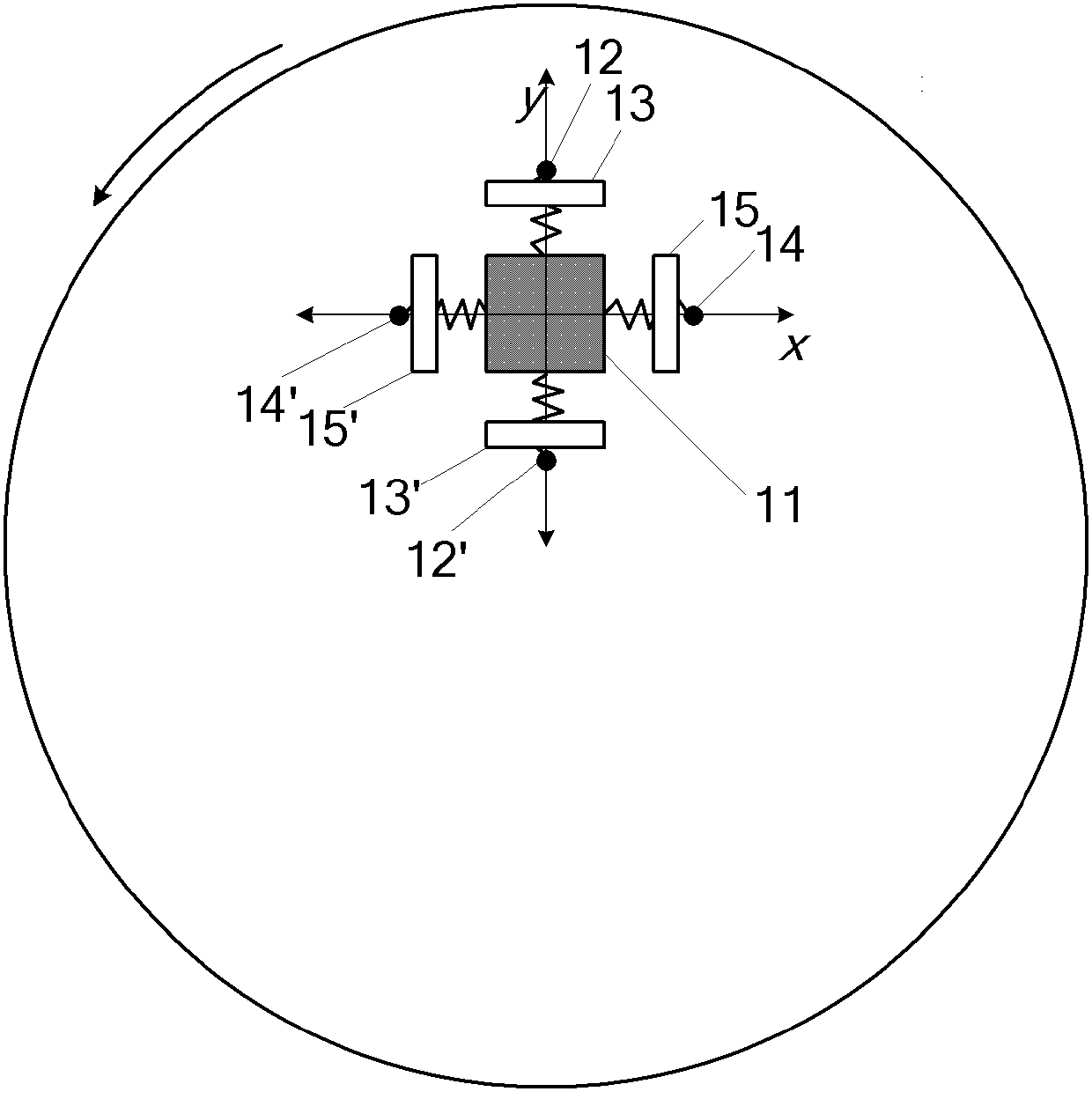

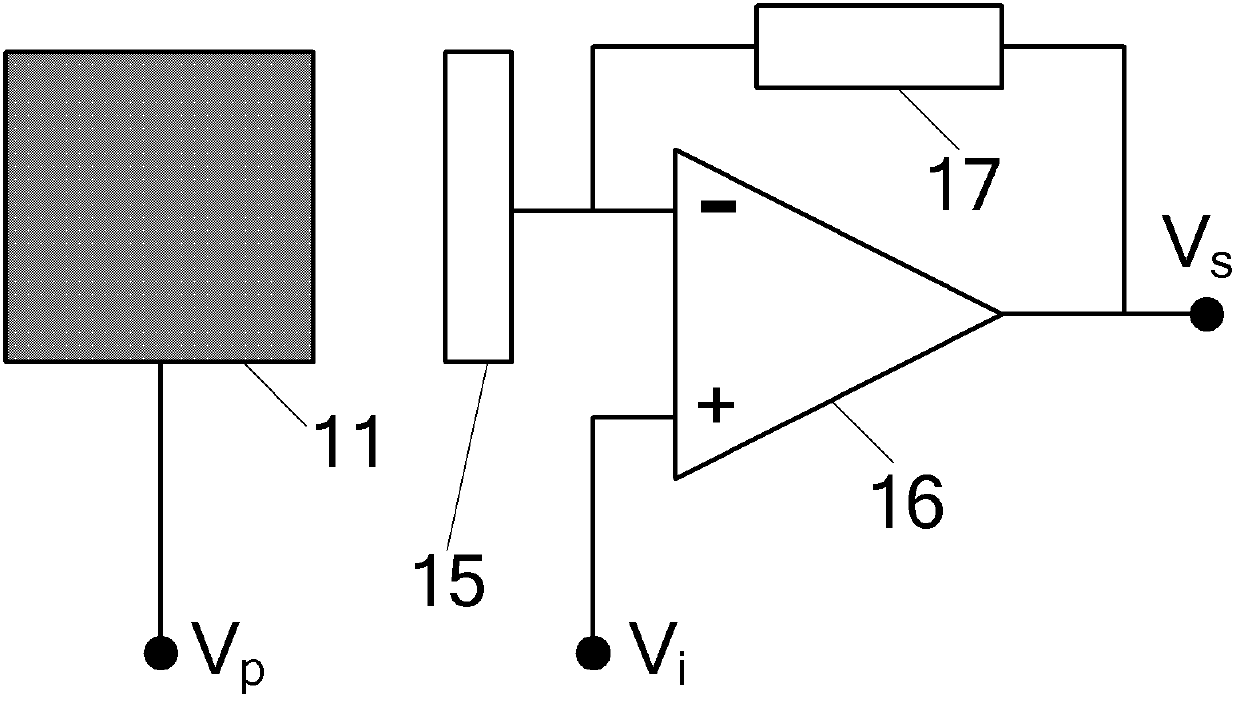

[0027] According to the present invention, the resonant frequency adjustment of the detection end of the capacitive MEMS gyroscope can be realized by connecting the output signal of the PI controller to the detection end of the MEMS gyroscope, and the principle is as follows:

[0028] For capacitive MEMS gyroscopes, it has resonance characteristics at the driving end and detection end, and its resonance frequency is determined by the mass of the mass and the stiffness it receives; stiffness includes two parts, namely mechanical stiffness and electrical stiffness; mechanical stiffness and device The geometrical size and material are related, and the bias voltage between the center mass and the fixed monitoring electrode det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com