Simultaneous monitoring method for welded steel truss structure fatigue failure process

A truss structure, fatigue failure technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve problems such as hindering the development and application of the system, poor identification ability, etc., to achieve the effect of improving test accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

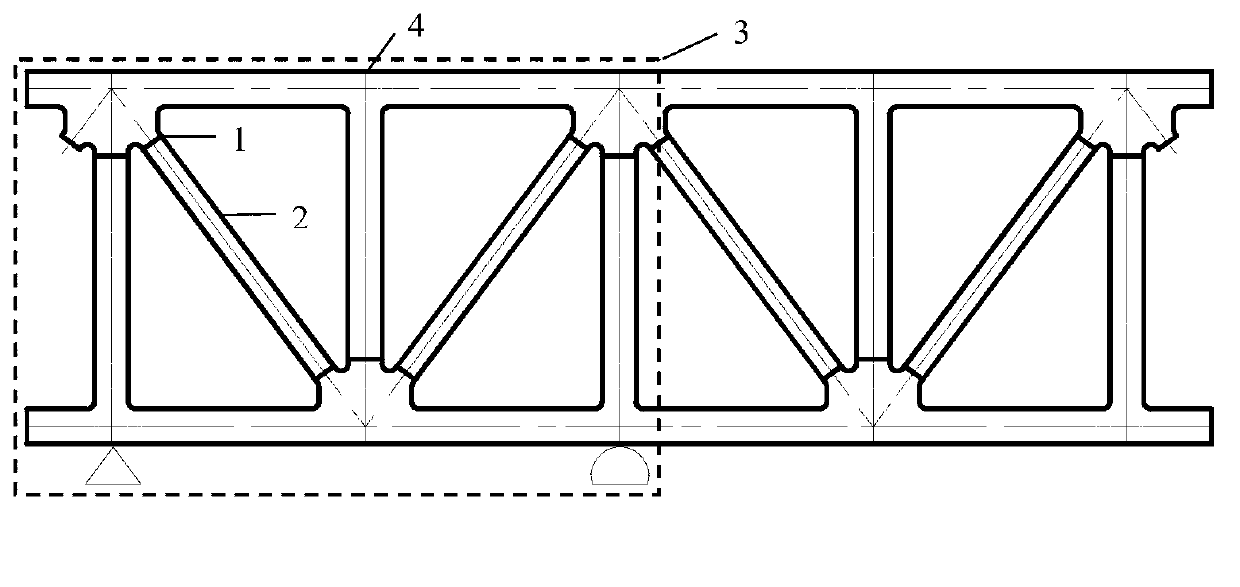

[0029] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the welded steel truss model in this embodiment is a scaled-down model of a large bridge steel box girder longitudinal stiffening truss, which is assembled by welding bridge steel plates, and its structural configuration, The welding method and processing technology are consistent with the original structure.

[0030] This embodiment includes the following specific steps:

[0031] The general finite element program ANSYS is used to establish the finite element model of the welded steel truss, and the local mesh geometry refinement is carried out according to the analysis target, such as figure 1 As shown, the model is simulated using the four-node elastic-plastic shell unit shell181, including a total of 45624 units, the material elastic modulus is 206GPa, the density is 7850kg / m3, and the Poisson’s ratio is 0.2588; the model completely reflects the geometri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com