Infrared gas sensor

A gas sensor, infrared receiver technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of poor real-time performance, increased production cost and installation difficulty, slow gas exchange speed, etc., to reduce light energy leakage, avoid The loss of infrared light energy, the effect of improving the reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

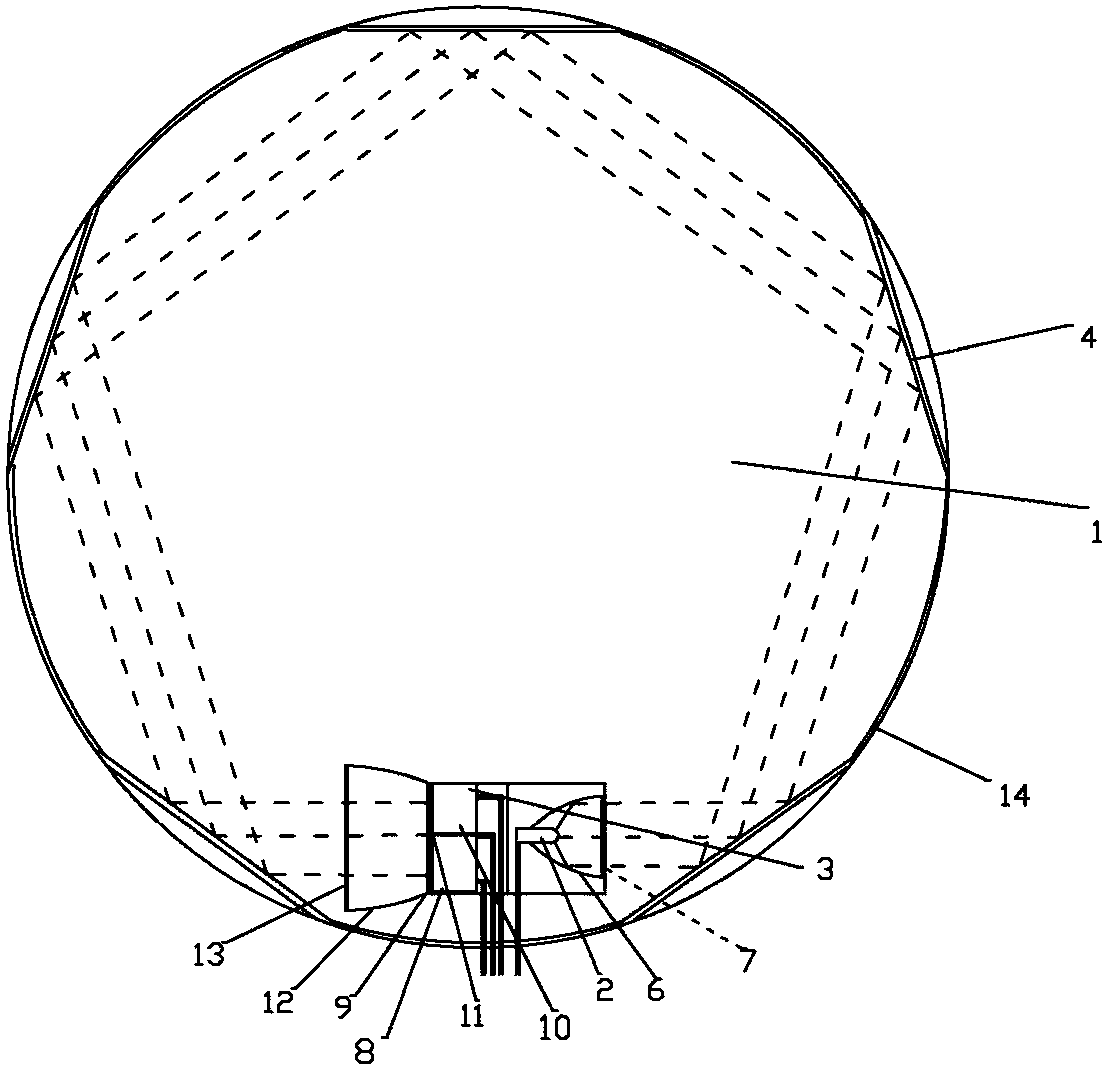

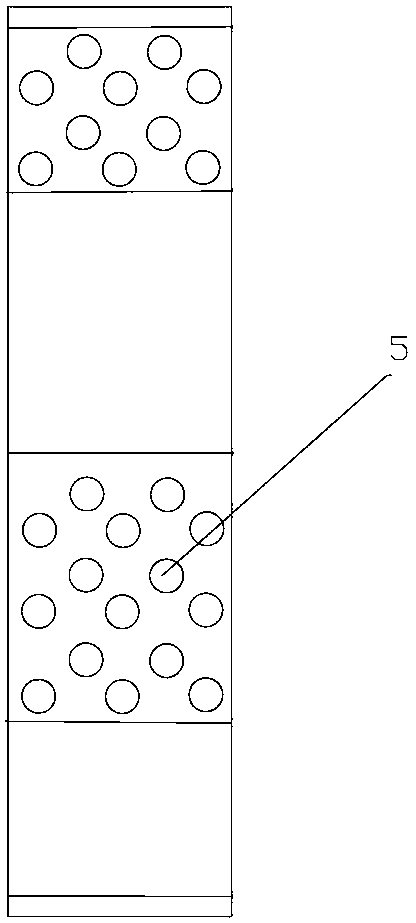

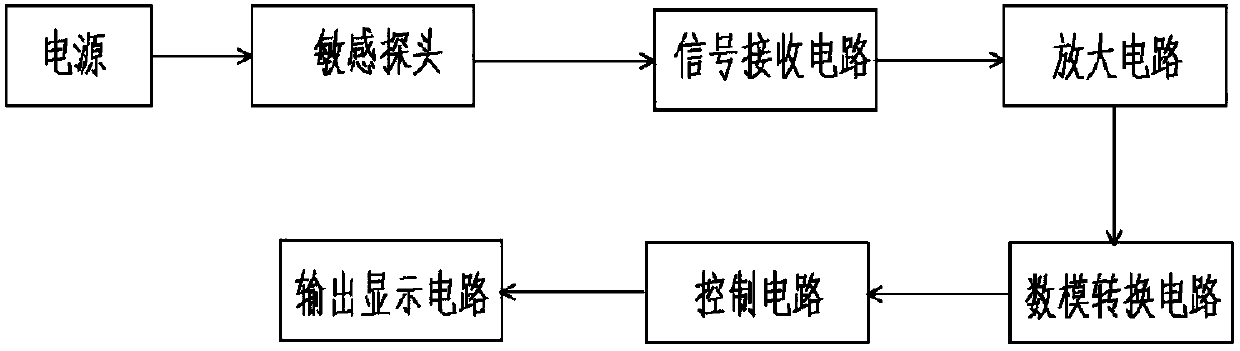

[0025] like figure 1 , 2 As shown, an infrared gas sensor includes a power supply connected in sequence, a sensitive probe, a signal receiving circuit, an amplification circuit, an analog-to-digital conversion circuit, a control circuit, and an output display circuit. The sensitive probe includes a gas chamber, an infrared light source, an infrared receiving device and five reflectors arranged at equal intervals on the inner wall of the gas chamber, the pins of the infrared light source and the infrared receiver pass through the gas chamber wall and are connected to the external circuit, and the infrared receiver includes a detection terminal and a reference terminal , the detection end consists of a first pyroelectric detector and a first filter sensitive to target gas, light intensity and temperature, and the reference end consists of a second pyroelectric detector and a filter sensitive only to light intensity and temperature Composed of the second filter; the infrared lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com