Height adjusting mechanism for accurate positioning of drawer slide

A technology of height adjustment mechanism and accurate positioning, applied in the direction of drawers, furniture parts, household appliances, etc., can solve the problems of difficult positioning of adjustment blocks, cumbersome adjustment procedures, loose overall structure, etc., to achieve reliable performance, accurate and stable positioning, Assemble the effect of quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

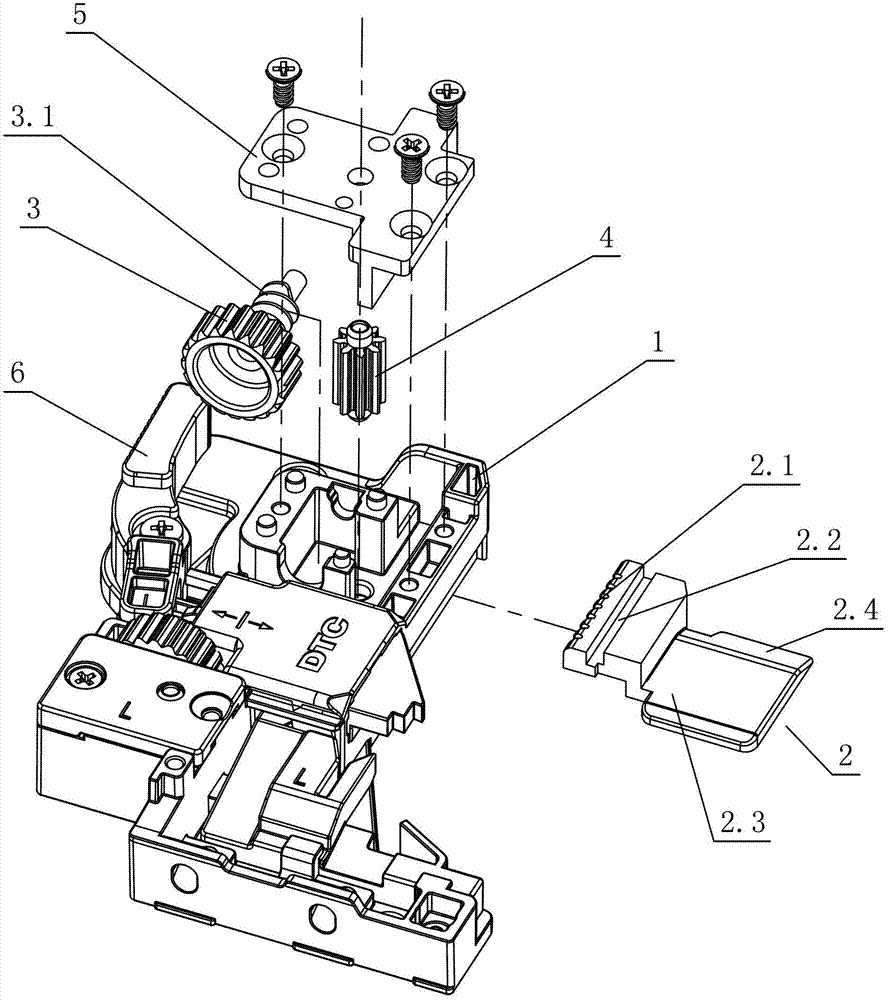

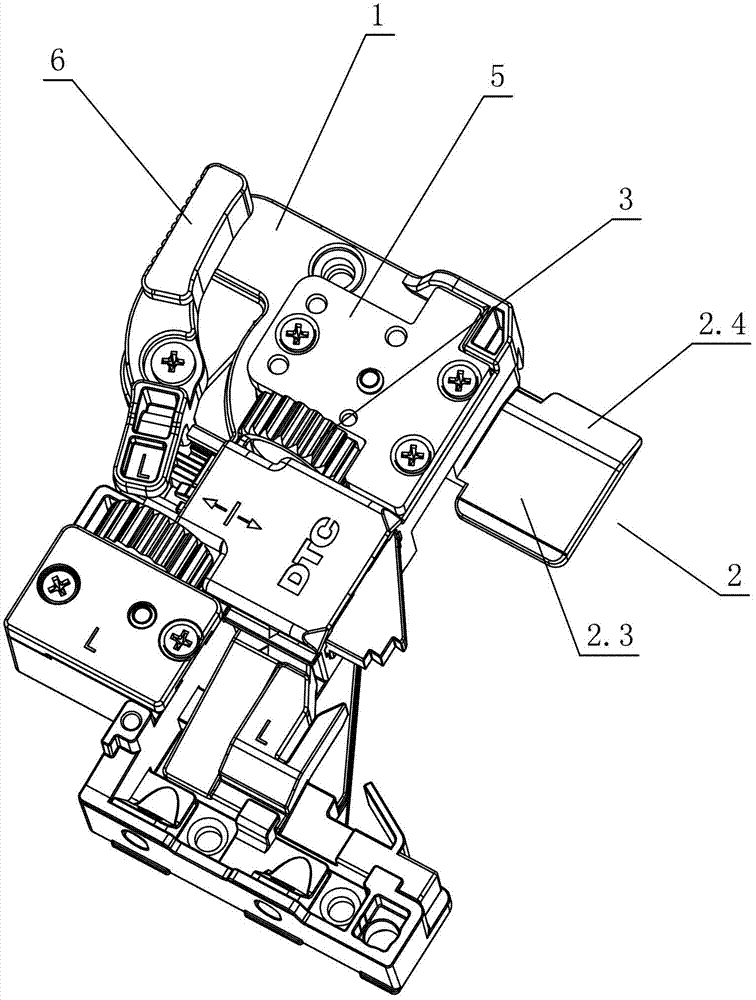

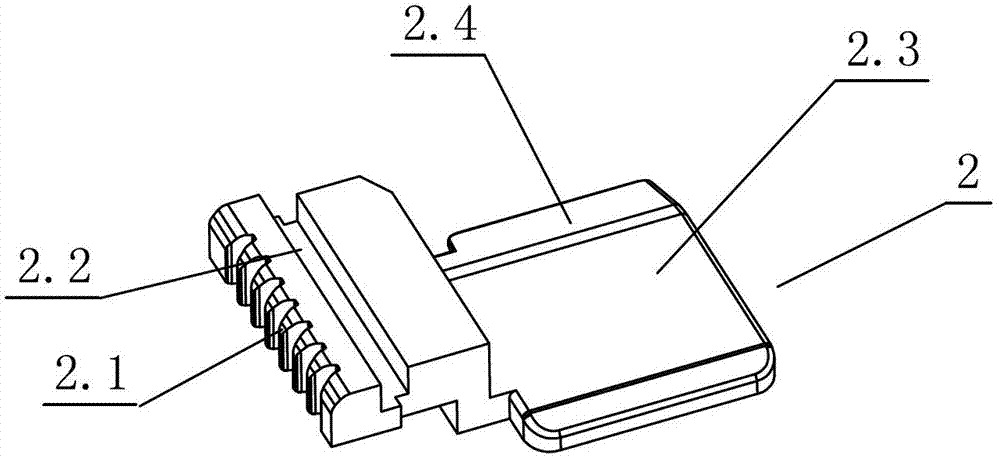

[0024] see Figure 1-Figure 10 The height adjustment mechanism for accurate positioning of the drawer slide rail includes a coupling seat 1 that is arranged at the bottom of the drawer 100 and is detachably connected with the pull-out rail 201 in the slide rail assembly. The slide rail assembly includes at least a certain rail and a A pull-out rail 201 is characterized in that an adjustment mechanism for adjusting the height of the drawer 100 is provided on the connection seat 1, and the height adjustment mechanism includes a wrench or a runner 3 arranged on the connection seat 1, and a height adjustment mechanism for adjusting the height of the drawer 100. The adjustment block 2, the wrench or the wheel 3 and the adjustment block 2 are connected by an engaging transmission; the adjustment block 2 is supported on the pull-out rail 201 for at least a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com