Garbage classification robot and garbage identification and classification method

A technology of garbage sorting and sorting methods, which is applied in sorting, manipulators, manufacturing tools, etc. It can solve the problems of various image recognition algorithms, rigidity, garbage sorting errors, etc., and achieve the effect of high technical content, making up for errors, and avoiding slow recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

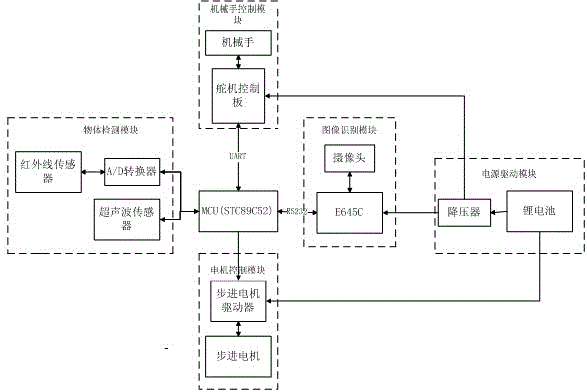

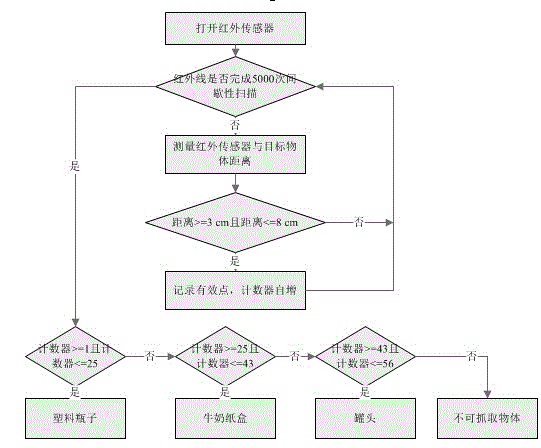

[0027] The invention provides a garbage sorting robot including a manipulator, a trolley chassis, two driving wheels, two universal wheels, processing platform equipment, ultrasonic infrared sensors, lithium batteries and a garbage bin. The trolley can be divided into two layers. The manipulator is placed at the front of the bottom of the trolley to connect with the film, the dustbin is placed in the middle of the chassis, the intelligent processing platform is placed at the rear of the upper trolley, the lithium battery is placed at the back of the bottom of the trolley, and the infrared sensor is installed on the manipulator. , the ultrasonic sensor is installed at the front end of the trolley. The robot can automatically find and identify garbage, and use the manipulator to grab it. It can sort plastic, paper, and cans into three types of garbage.

[0028] Such as figure 1 , figure 2 As shown, after the system is powered on and initialized, the lower computer asks the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com