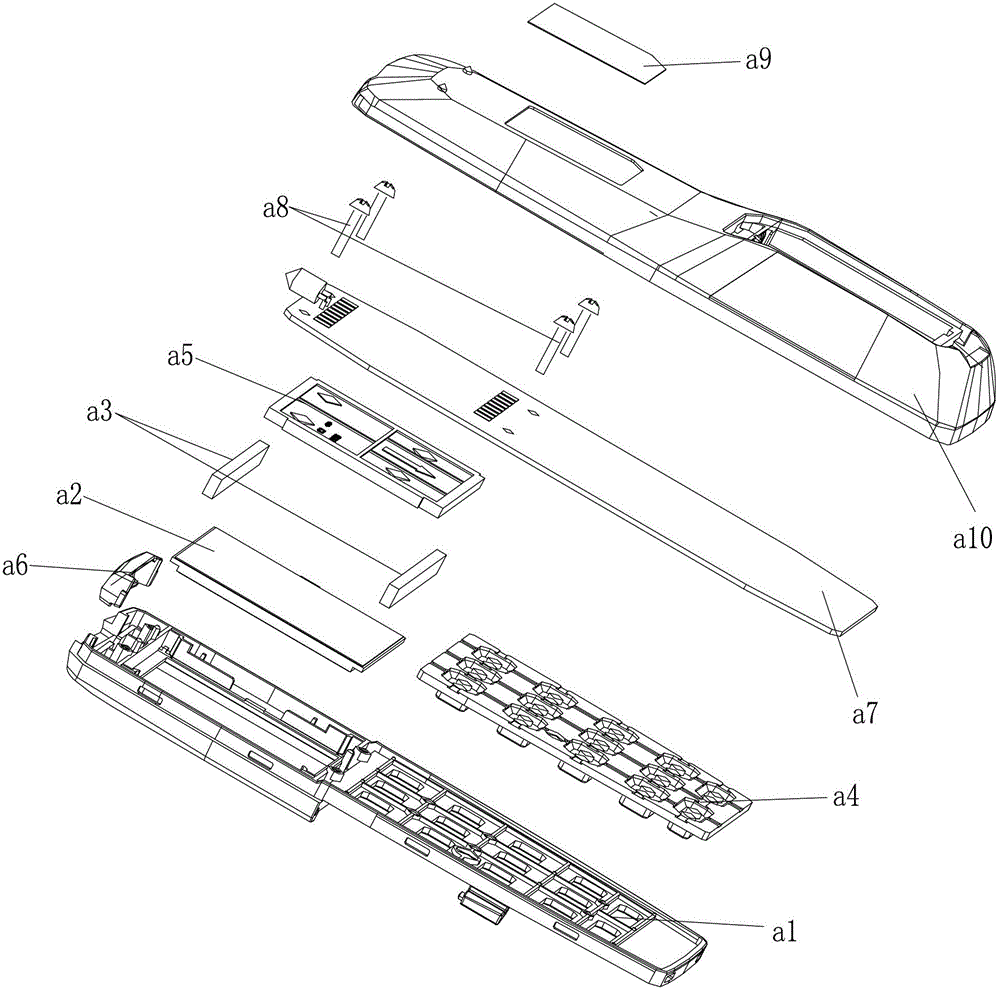

Automatic assembling machine and automatic assembling method for air conditioner remote controller panel

An automatic assembly machine and remote control technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as troublesome and time-consuming, missing or wrong assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

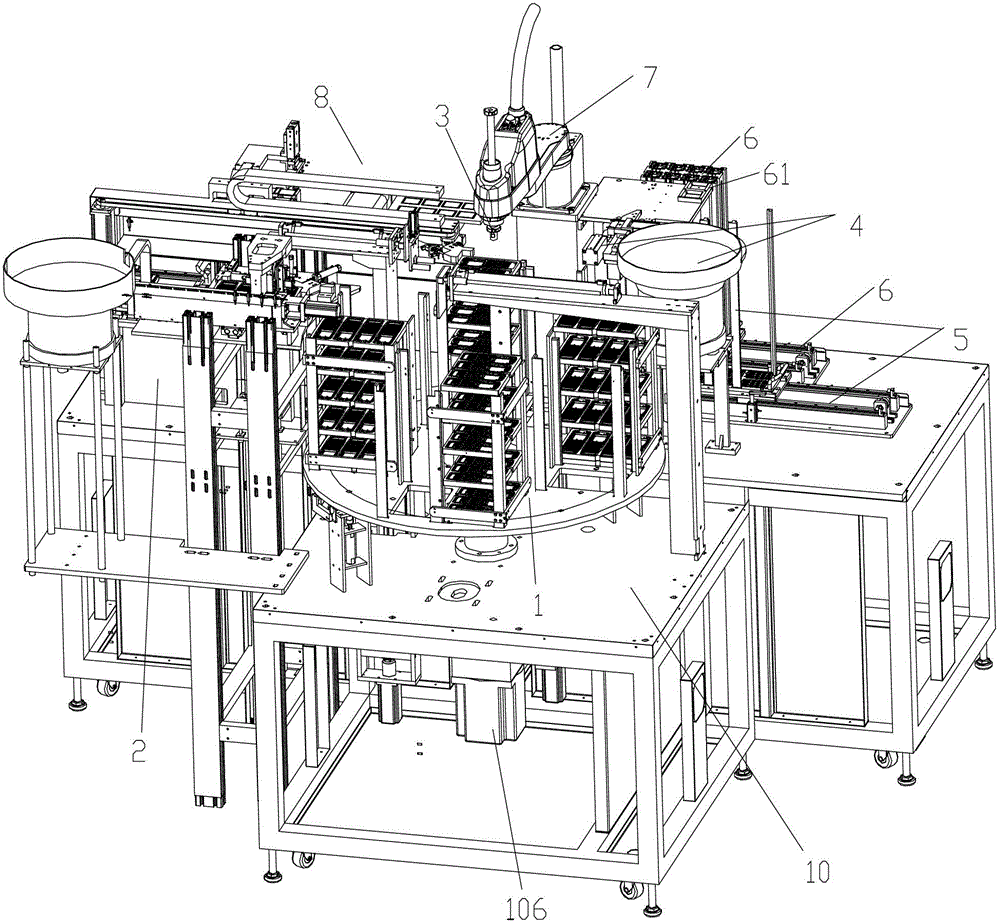

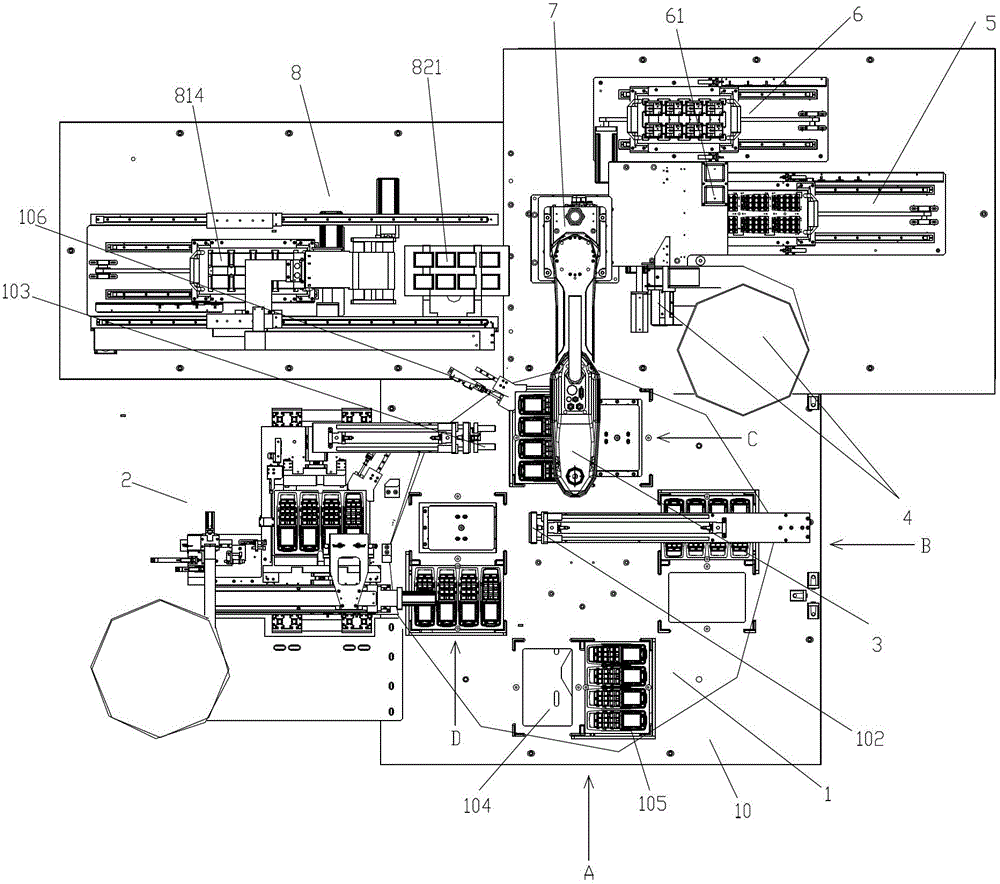

[0041] The automatic assembly machine of the air conditioner remote control panel of the present invention at least includes such as figure 2 and 3 The shown panel material tray feed transfer device 1, launch window feed assembly device 2, panel assembly combination gripper device 3 and panel assembly manipulator 7, such as Figure 7 and 8 The shown panel assembly combined gripper device 3 is fixed on the output shaft of the panel assembly manipulator 7 through the assembly plate 36, and the output shaft has the ability to move in the first horizontal direction, the second horizontal direction and the vertical direction orthogonal to each other. And four degrees of freedom of rotation around the central axis of the output shaft, including three degrees of freedom of movement in space and one degree of freedom of rotation around the central axis of the output shaft, to meet the needs of grasping parts and assembling parts .

[0042] like Figures 2 to 5 As shown, the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com