Mold mechanism realizing inner core extraction by oblique ejectors and outer core extraction by outer sliding blocks

A technology of mold mechanism and slider, which is applied in the field of mold mechanism for drawing outer core by slider and inner core for inclined top, which can solve the problems of difficult to achieve mold clamping force, inconvenient manufacturing, installation, debugging, maintenance, and mold manufacturing cycle. Lengthening and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

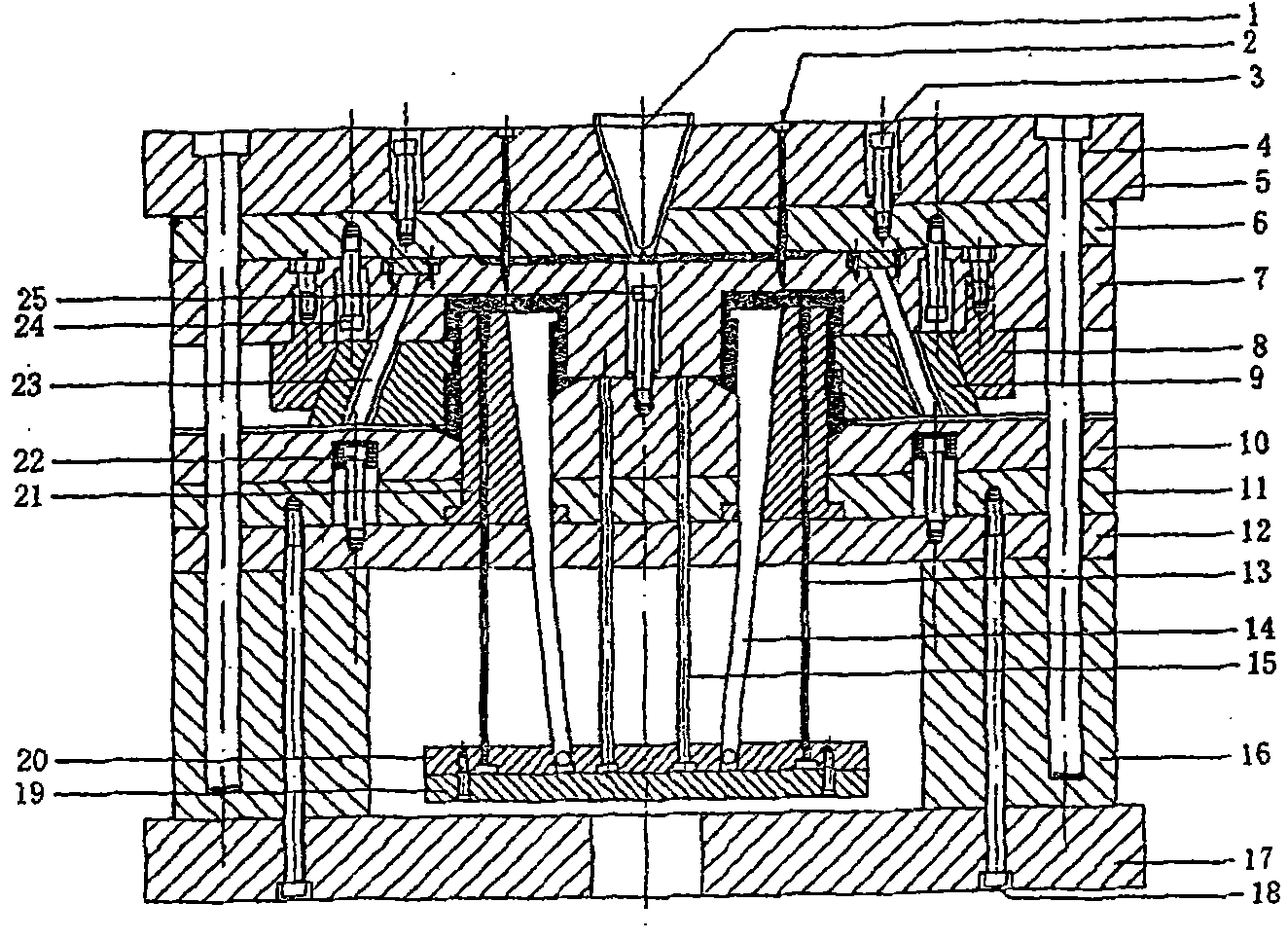

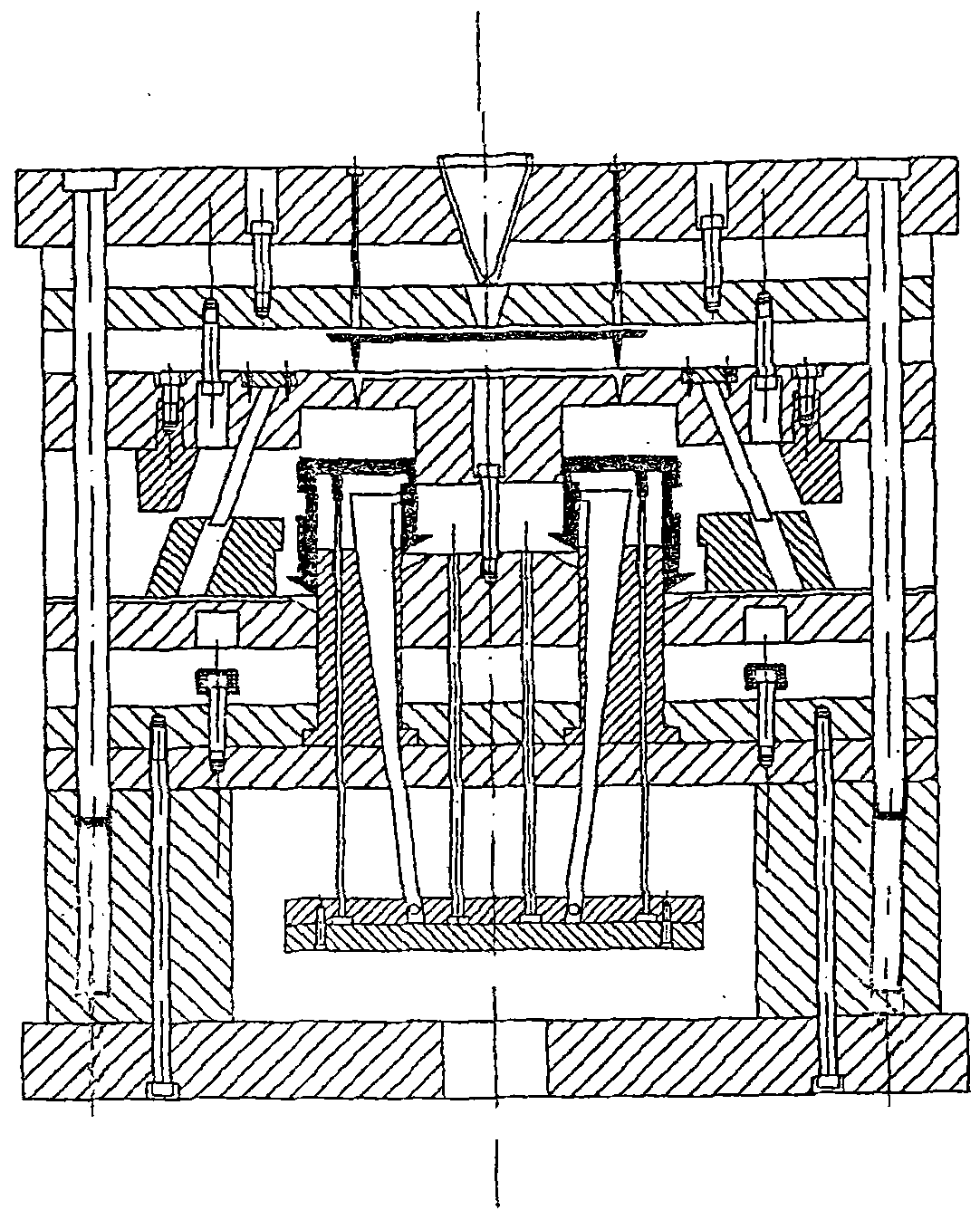

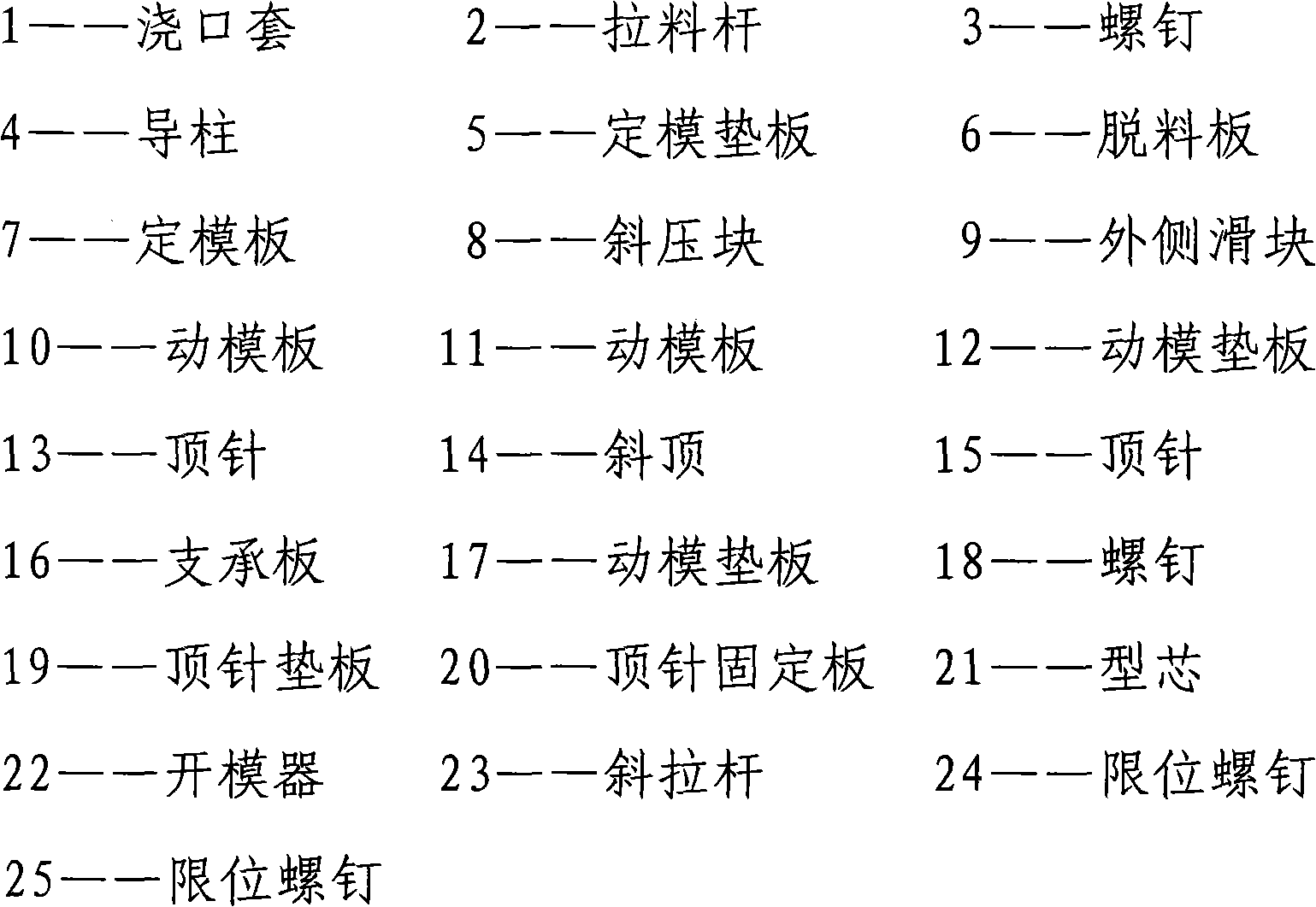

[0010] As shown in the figure, it is a mold mechanism in which the inclined top draws the inner core and the slider draws the outer core. Its specific implementation is as follows:

[0011] After the mold is injected or die-casted, the movable mold part of the mold moves with the injection machine or die-casting machine, and the product is pulled to the movable mold side by the core (21). At this time, the diagonal tie rod (23) installed on the fixed mold side forces the outer slider (9) In the T-shape of the movable template (10), make a sliding action in the direction of the outer side of the mold, and slide until there is a 3-4 mm gap between the molding part of the outer slider (9) and the product, and then the outer slider (9) stops moving. , so as to achieve the purpose of core pulling on the outer surface. The movable mold continues to move. When the mold opening distance is greater than the height of the product, the injection machine or die-casting machine stops. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com