Mini-type gear drive mechanism of temperature-sensitive printer

A technology of gear transmission mechanism and thermal printer, which is applied in printing and other directions, can solve the problems of reduced gear train life, broken gear transmission mechanism, and high maintenance cost of the transmission mechanism, and achieves small size, affordable, and high-quality gear transmission mechanism. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

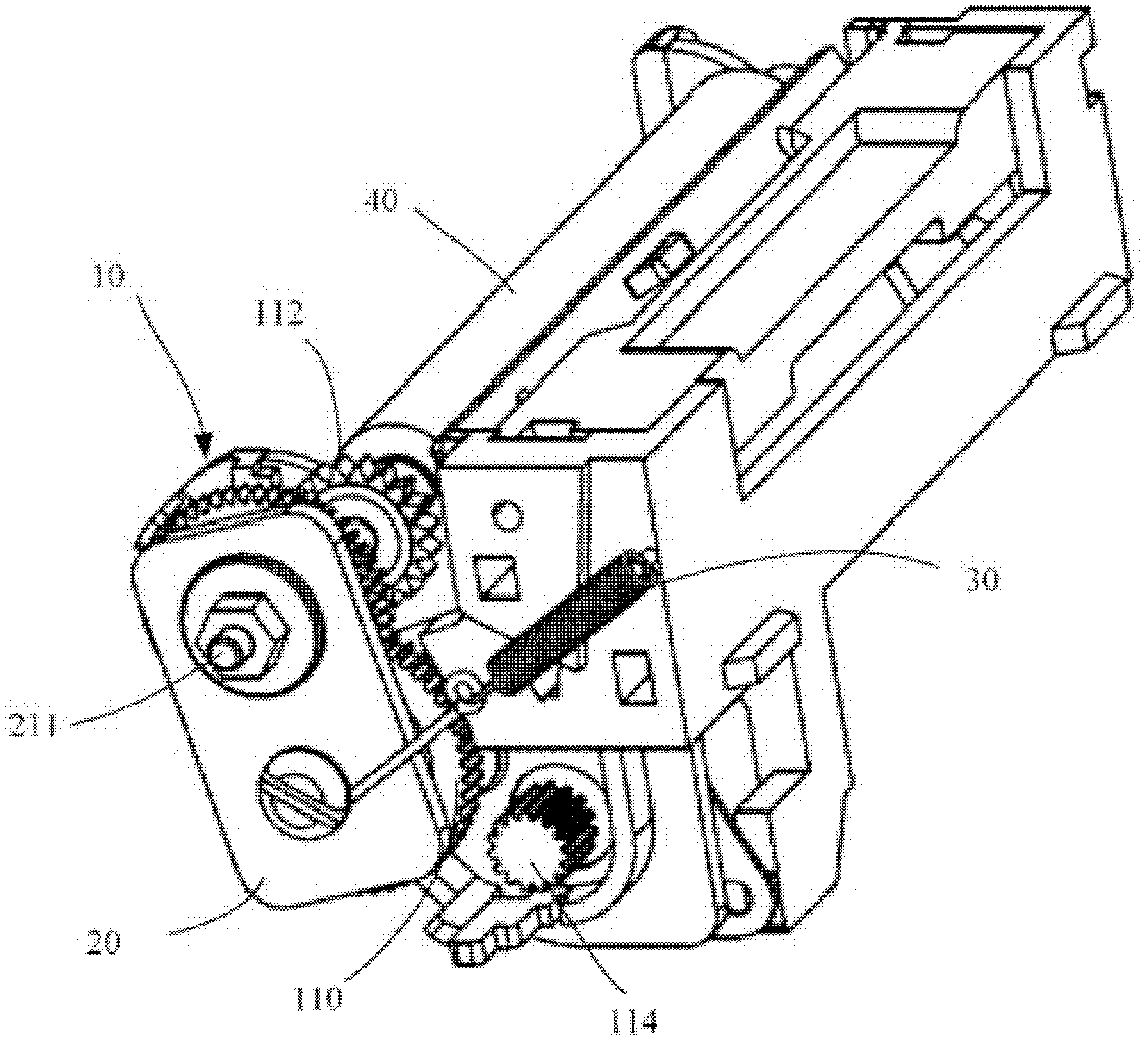

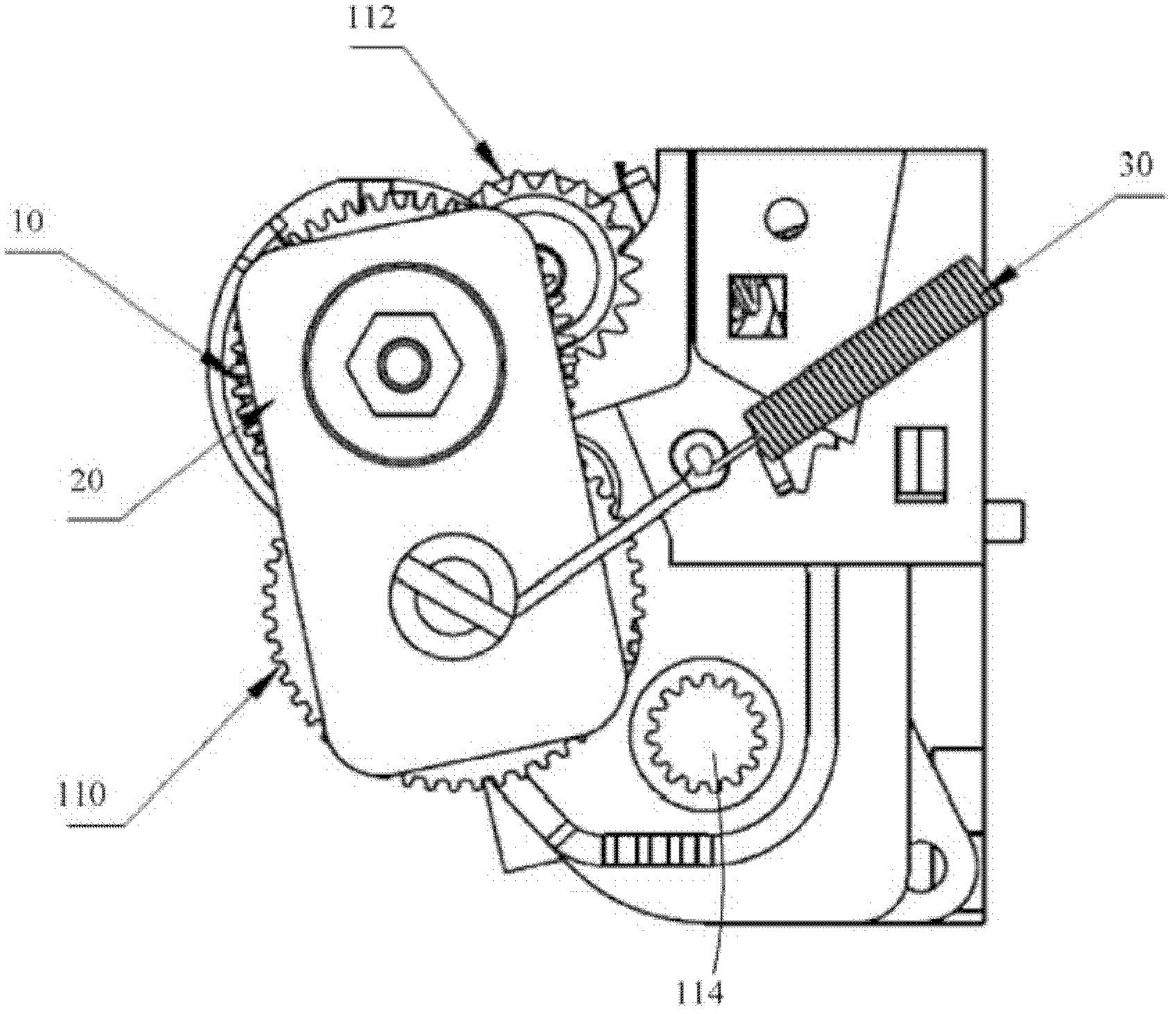

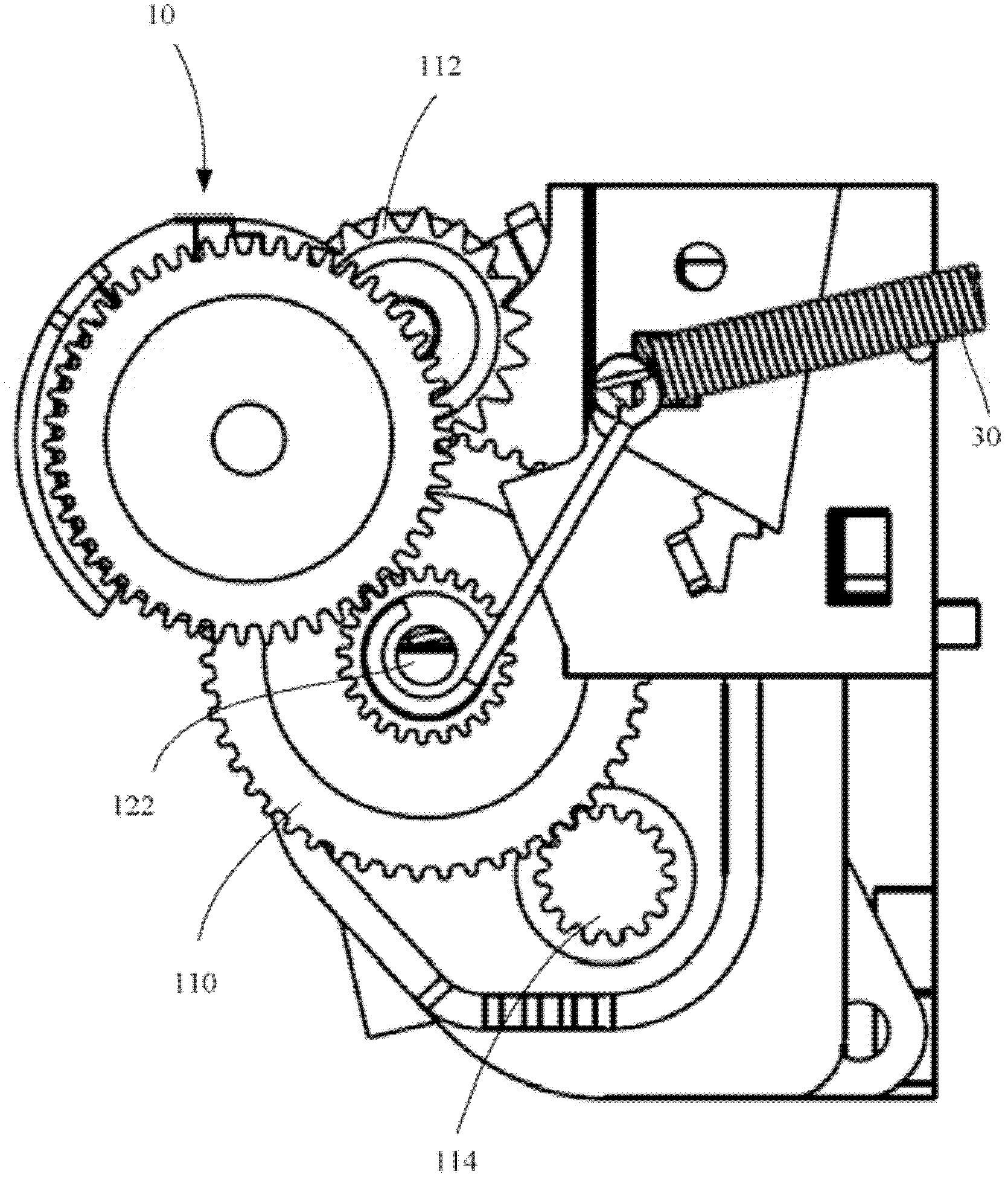

[0023] Such as figure 1 with figure 2 As shown, the gear transmission mechanism of the micro thermal printer includes a gear train 10, a movable plate 20 and a spring 30. The gear train 10 includes a plurality of fixed gears with fixed axes and a movable gear 110 with a movable axis. Among the multiple fixed gears, the motor gear 114 connected to the output shaft of the stepping motor is located at one end of the gear train, and the roller gear 112 coaxially connected to the rubber roller 40 is located at the other end of the gear train. Among the multiple fixed gears There are other gears, so I won’t repeat them here. In the gear train 10, the movable gear 110 is located between the roller gear 112 and the motor gear 114. Preferably, the movable gear 110 meshes adjacently with the motor gear 114, but is not limited to this. For example, the movable gear 110 may be engaged with a roller. The gears 112 are meshed adjacently, or there are other gears spaced apart.

[0024] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com