Ordinary gear train and non-uniform transmission mechanism combined power transmission device

A technology of transmission mechanism and fixed axle gear train, applied in the direction of gear transmission, differential transmission, transmission, etc., can solve the problems of difficult processing, low power density, difficult to balance the whole machine, and achieve the stability of the whole machine Improves, prolongs service life, and facilitates balanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

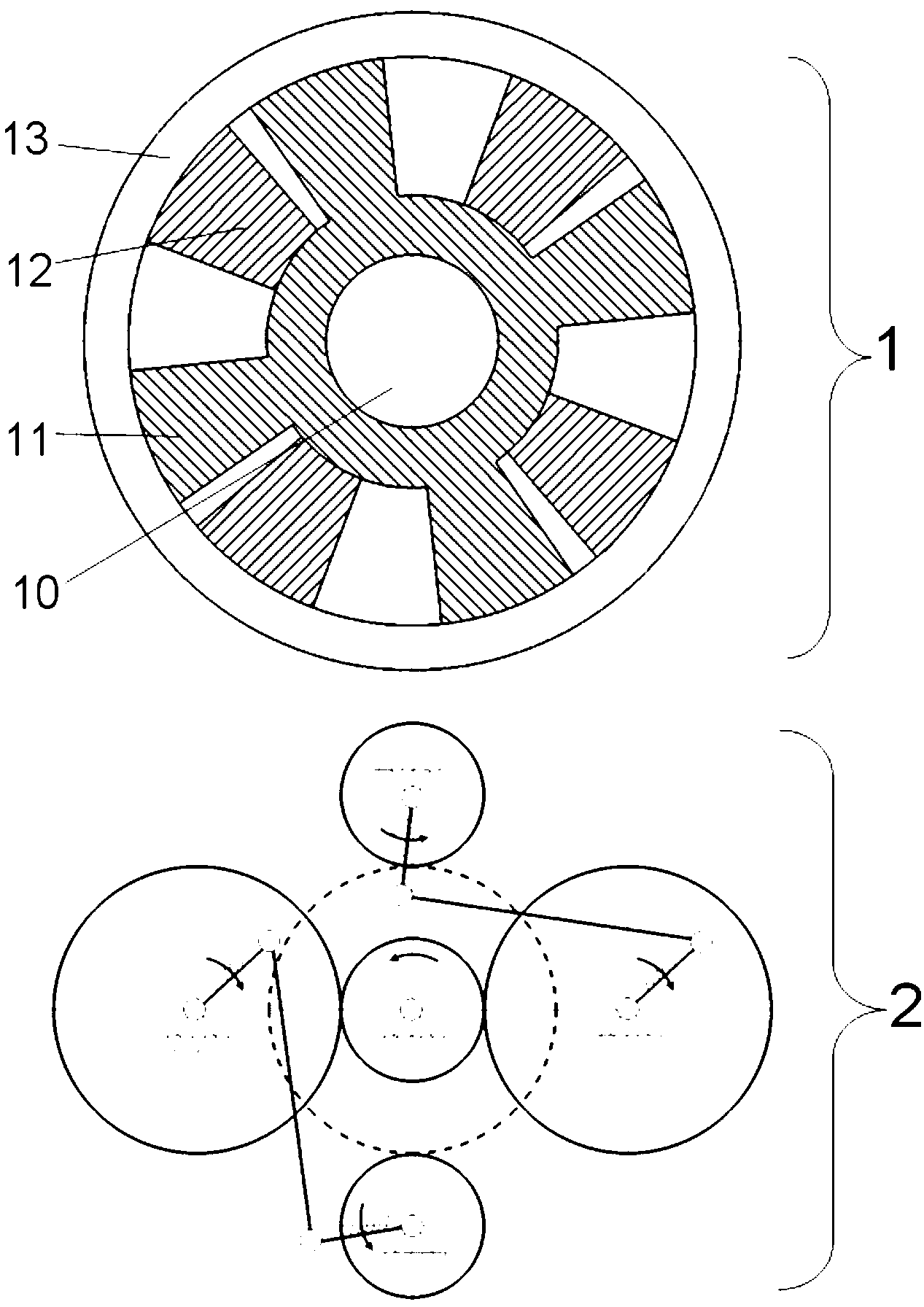

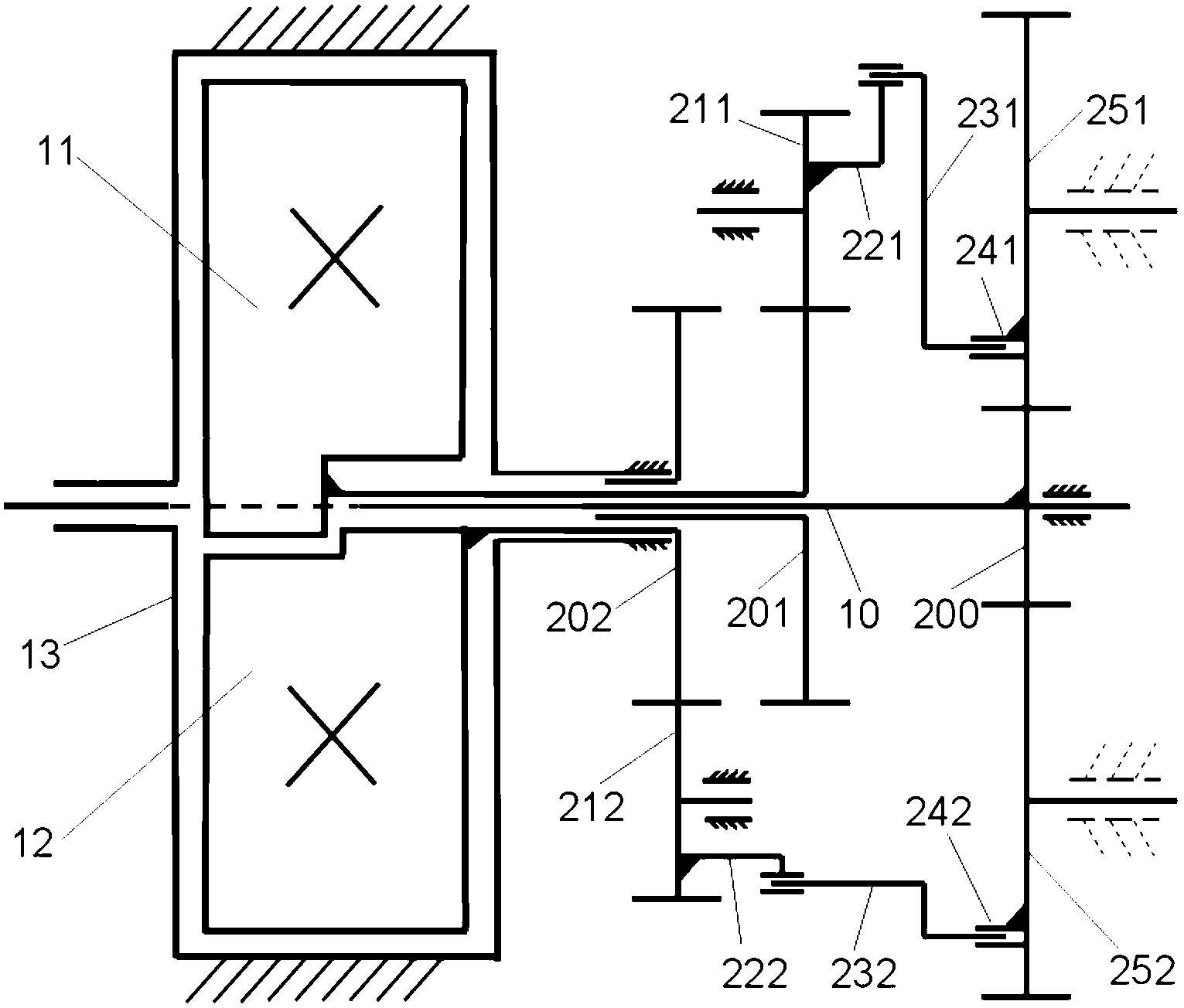

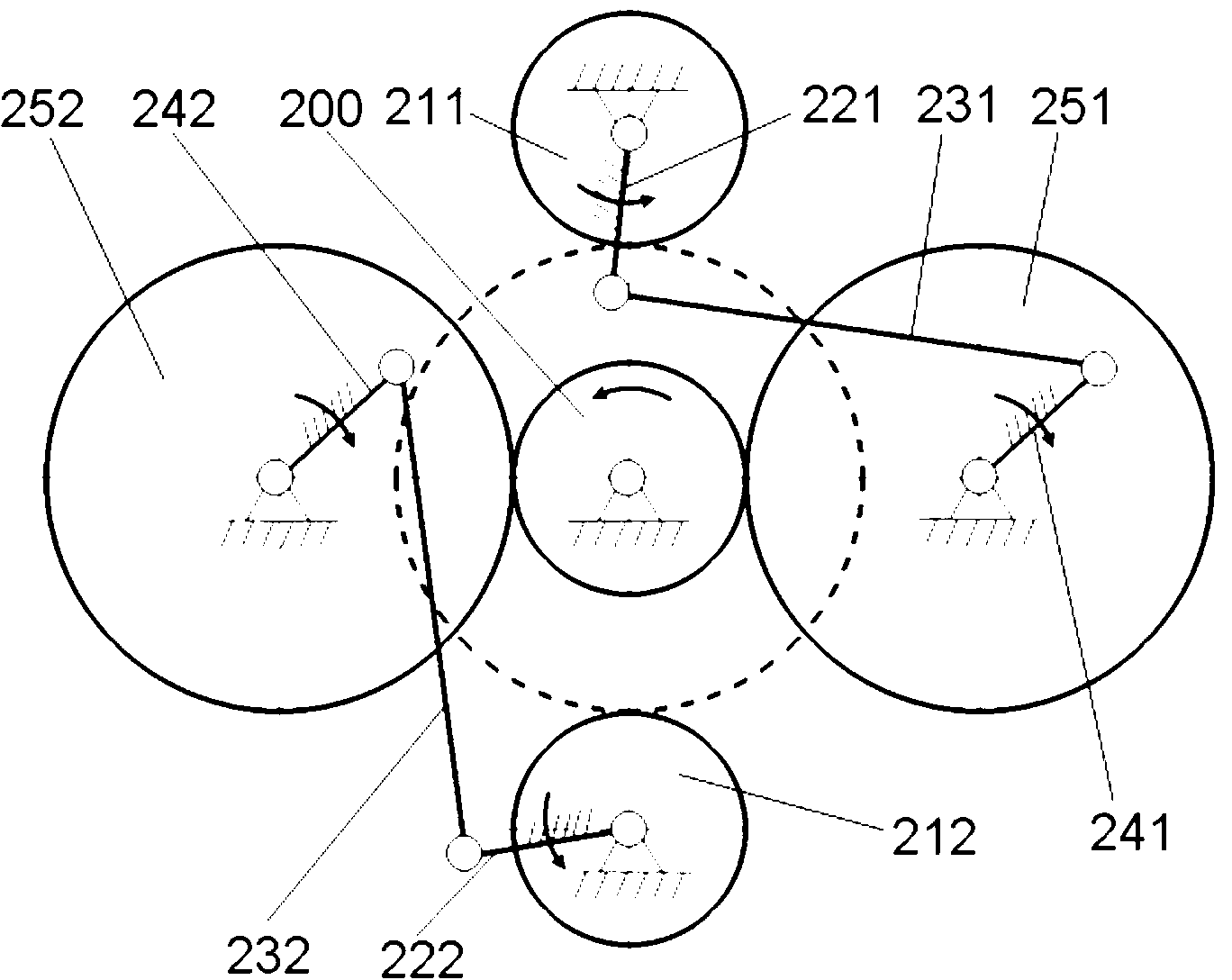

[0035] Such as figure 1 , figure 2 , image 3As shown, in the first embodiment, the power transmission device of the present invention combining a fixed-axis gear train and a non-uniform speed transmission mechanism includes a power cylinder assembly 1, a power shaft 10, and a differential drive assembly 2 connected to the power cylinder assembly 1, The power cylinder assembly 1 includes a rotor I11, a rotor II12 and a cylinder body 13. The rotor I11 and the rotor II12 are coaxially installed in the cylinder body 13 in a cross shape and can rotate around the axis of the power shaft 10. The differential drive assembly 2 includes a set of fixed-axis gear trains and two sets of non-uniform speed transmission mechanisms. The fixed-axis gear train and non-uniform speed transmission mechanisms are combined to form a drive assembly with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com