Filling mining method of gently inclined thin mineral deposit with soft roof

A technology of filling mining and gentle inclination, which is applied in the direction of filling, ground mining, mining equipment, etc., which can solve the problems of increased mining cost and stope management complexity, unsuitable for thinner deposit mining, difficult support and maintenance, etc. , to achieve the effect of low bulk rate, operation safety protection and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention relates to a filling mining method for a thin ore deposit with a gently inclined soft roof. The method is:

[0040] 1) Sampling and cutting

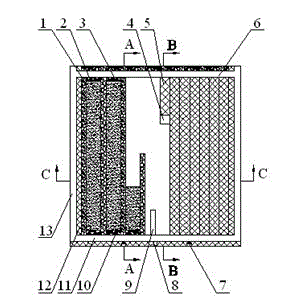

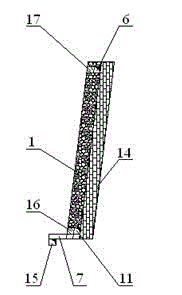

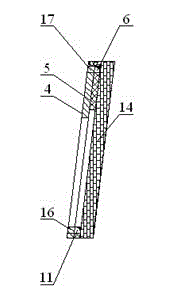

[0041] Divide the thin ore deposit with gently inclined soft roof into panels, each panel such as figure 1 and Figure 5 As shown, on the top of the ore body 4 of the panel area to be mined, the upper segmented scraper road 6, the lower segmented scraper road 11 and the ventilation uphill 13 are excavated. Such as figure 2 Shown are Upper Scraper Lane 6, Lower Scraper Lane 11 and Figure 4 The roof of the shown ventilating uphill 13 is the firm roof 14 of ore body 4; figure 1 , figure 2 and Figure 5 As shown, the 3-5m thick intercolumns 12 are left on both sides of the ventilated uphill 13, and the air inlet shaft 8 and the slip shaft 7 are excavated in the unmined panel area of the next segment of the panel area to be mined. 8 and the chute 7 are communicated with the subsection transportation roadway 1...

Embodiment 2

[0065] The invention relates to a filling mining method for a thin ore deposit with a gently inclined soft roof. Except following parameter or technique, all the other are with embodiment 1.

[0066] The stable roof 14 of the gently inclined soft-roof thin deposit described in this embodiment is a relatively stable roof, and the panel area to be mined is divided into 20-30 strips, and the width of each strip is 5-8m. The empty area formed after the mining of the penultimate strip of the panel is filled with the waste rock produced by removing the soft roof 5 from the first and second strips of the next panel by grouting upwards along the strip. The width is also half of the width of the strip. When the second-to-last strip is filled with waste rock grouting for 10-20m, start to fill the empty area formed after the mining of the penultimate strip and the second-to-last strip with upward tailings along the strip. For the other half of the strip waste rock grouting filling, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com