Step-up gear box for wind power generator

A technology for wind turbines and gearboxes, which is applied to gear transmissions, belts/chains/gears, transmission boxes, etc. It can solve the problems of high manufacturing cost of gearboxes, heavy weight of gearboxes, and low transmission efficiency, and achieve weight reduction. Light, reduce weight, improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

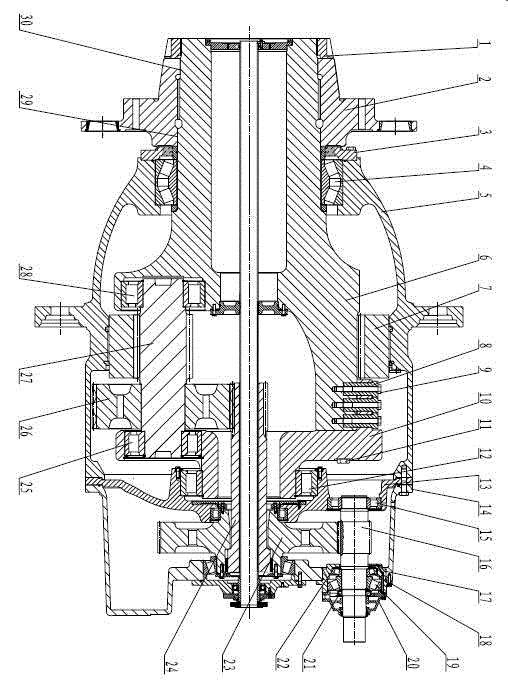

[0020] In order to further understand the speed-up gearbox for wind turbines, combined with the attached figure 1 described as follows.

[0021] It is mainly composed of a box body, a first-level compound planetary gear train and a speed-up transmission mechanism composed of a first-level fixed-axis transmission in series; the box body includes: a front box body 5, a middle box body 13 and a rear box body 14, and the front box body Body 5, middle box body 13 and rear box body 14 are fixed as a whole by bolt; Front box body 5 is provided with process hole, and it is convenient for the installation and dismounting of pin sleeve 8 and first bolt 9; Described compound planetary gear train comprises The first half of the planetary carrier 6, the second half of the planetary carrier 10, the ring gear 7, the planetary wheel shaft 27 and the planetary gear 26, the first half of the planetary carrier 6 and the second half of the planetary carrier 10 pass through the pin sleeve 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com