High-efficiency dryer

A high-efficiency, dryer technology, used in dryers, drying, non-progressive dryers, etc., can solve the problems of single movement mode, inability to achieve results, poor drying effect, etc., and achieve good drying effect and structure. Simple, excellent drying results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

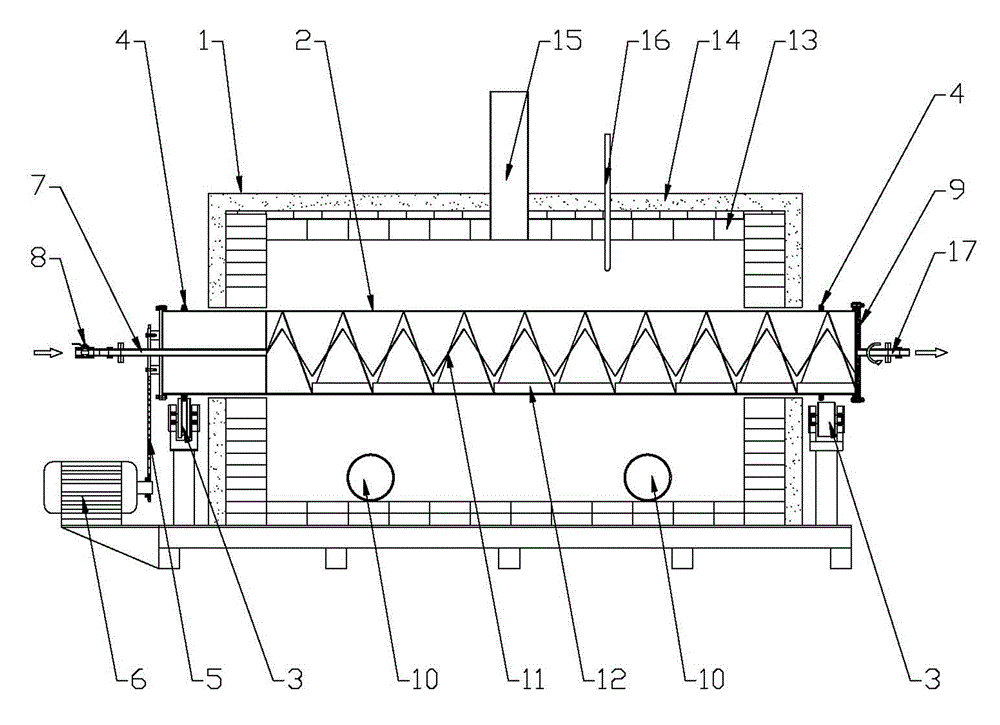

[0019] Such as figure 1 Shown: a high-efficiency dryer, including a furnace body 1 made of refractory bricks 13 and an insulating layer 14 from the inside to the outside, and a furnace body 2 made of heat-resistant steel 310S. The furnace body 1 is provided with a chimney 15 and a temperature sensor The probe 16, the furnace body 2 is horizontally arranged in the furnace body 1 and the two ends of the furnace body 2 extending out of the furnace body 1 are supported by supporting rollers 3, the supporting rollers 3 are in contact with the rolling ring 4 on the furnace body 2 and the furnace body 2 One end is connected to the output end of the variable speed motor 6 through the transmission mechanism 5 made, one end of the furnace body 2 is provided with a feed pipe 7 and a valve 8 made of a high-temperature ball valve is provided on the feed pipe 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com