Method and device for supplying hot water used for production and living by waste heat of kiln

A technology for daily use and kiln, applied in furnaces, waste heat treatment, furnace components, etc., which can solve the problems of large consumption of electricity, coal, natural gas, and large demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

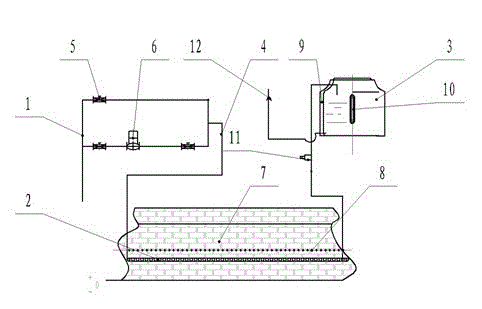

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The present invention uses the waste heat of the roller kiln, installs a Φ25-50mm copper heat pipe network inside the roller kiln, utilizes the waste heat radiation heating of the roller kiln, and enters the production through the pressure cycle and electric cycle of the water, and the domestic heat storage tower , and then flow to the demand point.

[0013] Such as figure 1 As shown, a device that utilizes kiln waste heat to solve production and domestic hot water, which consists of a water inlet device 1, a roller kiln cooling belt heat pipe network 2, and a water storage tower 3. Among them, the water inlet device 1 It is composed of water inlet pipe 4, shut-off valve 5 and booster pump 6; the heat pipe network 2 of the cooling zone of the roller kiln is set at the lower end of the kiln bed 8 of the cooling zone 7 of the roller kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com