strain sensor

A strain sensor and sensor technology, which is applied in the field of strain sensors, can solve the problems of casualties and economic losses, the decline in the ability to resist loads, the attenuation of cumulative damage resistance, etc., and achieve the effects of long service life, high measurement accuracy, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples.

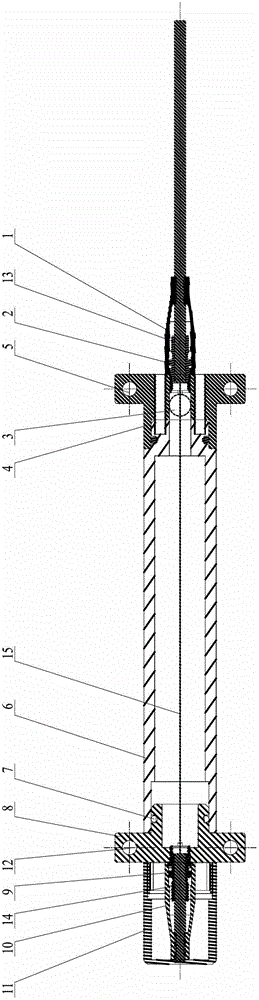

[0010] The strain sensor has a sensor front end cover 4 sealed and fixed on the front end of the sensor body 6, a first stopper 2 and a grating string 3 are fixed on the sensor front end cover 4, and a first stopper 2 is arranged outside the first stopper 2. The protective sleeve 1 has a first fiber optic sheath 13 fixed inside the first stopper 2, and a sliding block 8 is inserted into the rear end of the sensor body 6 for sliding sealing. The sliding block 8 can move along the axial direction of the sensor body 6. Sliding a certain distance, carry out on slide block 8 and be fixed with tail end cover 11, be fixed with second stopper 9 on the slide block 8 in tail end cover 11, be provided with second guard outside second stopper 9 Cover 10, a second fiber optic sheath 14 is fixed in the second stopper 9; an optical fiber 15 is arranged in the sensor body 6, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com