Monitoring device and networked automatic monitoring and recording system for pile hammering machine construction

A construction monitoring and automatic monitoring technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of fast beating rate, large error, inability to guarantee each pile, etc., to achieve a reasonable installation position, overcome the Large error, the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

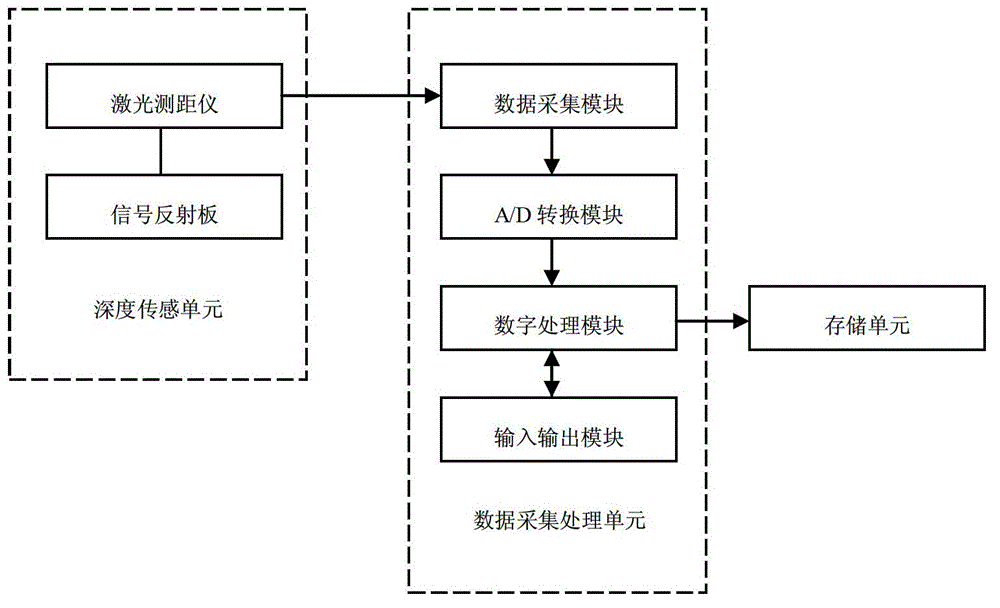

[0041] Such as figure 1 As shown, a construction monitoring device for a hammer pile machine includes a depth sensing unit for real-time acquisition of pile depth and a data acquisition and processing unit connected to the depth sensing unit.

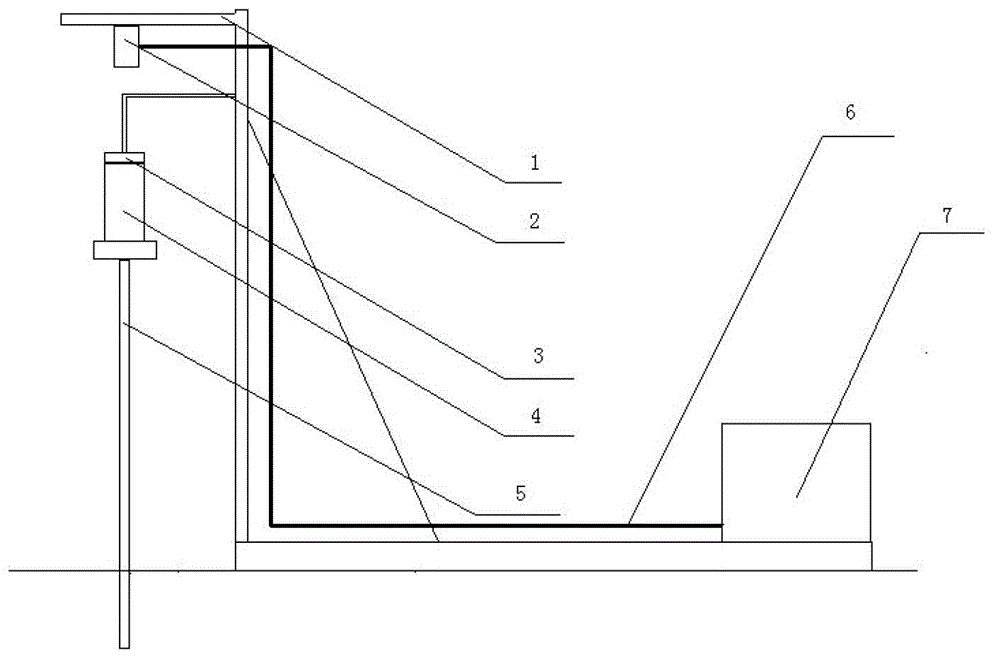

[0042] The depth sensing unit, such as image 3 As shown, it includes a rangefinder 2 installed on the top of the landing gear 1 of the hammer pile driver and positioned at the vertical top of the hammer body 4 of the hammer pile driver, for real-time monitoring of the distance between the top of the landing gear 1 and the upper surface of the hammer body 4 distance, and send the analog signal with the monitored distance information to the data acquisition and processing unit.

[0043] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com