Automatic recording instrument for static pressure pile construction and static pressure pile construction device

A technology of static pressure piles and recorders, which is applied in the direction of sheet pile walls, foundation structure engineering, foundation structure tests, etc., can solve the problems of inability to realize detailed investigation of stratum soft and hard changes, and can not guarantee, so as to reduce the number of building structures. The effects of cracking, durable structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

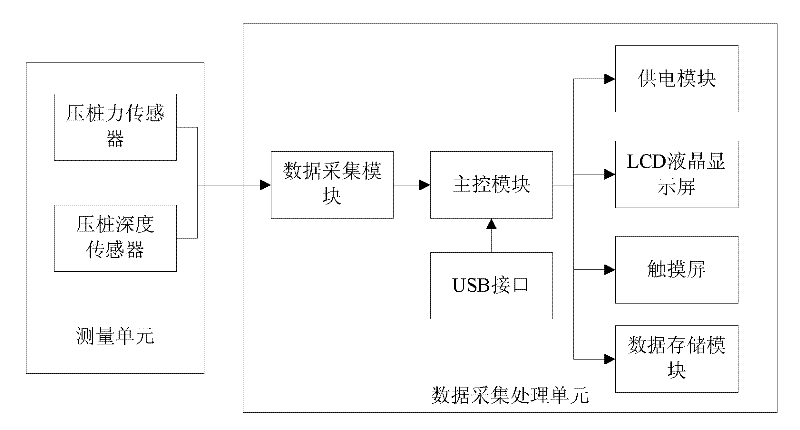

[0039] see figure 1 (The arrows between the components in the figure are only schematic, and do not strictly represent the data flow direction), a static pressure pile construction automatic recorder of the present invention includes a measurement unit and a data acquisition and processing unit, and the measurement unit includes pile pressure The force sensor and the pile depth sensor, and the data acquisition and processing unit includes a data acquisition module and a main control module connected to each other, wherein both the pressure pile force sensor and the pile depth sensor are connected to the data acquisition module.

[0040]In the data acquisition and processing unit, the main control module adopts ARM9 processor (central processing unit (MCU) S3C2440-40), the data acquisition module adopts PIC series single-chip microcomputer, and there is a matching communication protocol between the main control module and the data acquisition module. Ensure that the rate of dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com