Capacitive control screen with three-dimensional via hole and manufacturing method thereof

A manufacturing method and technology of via holes, which are applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem that the conductive interface is difficult to control, the insulating layer is difficult, and the position of the via hole is brittle. and other problems, to achieve the effect of improving the overall process quality, simplifying the manufacturing process, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

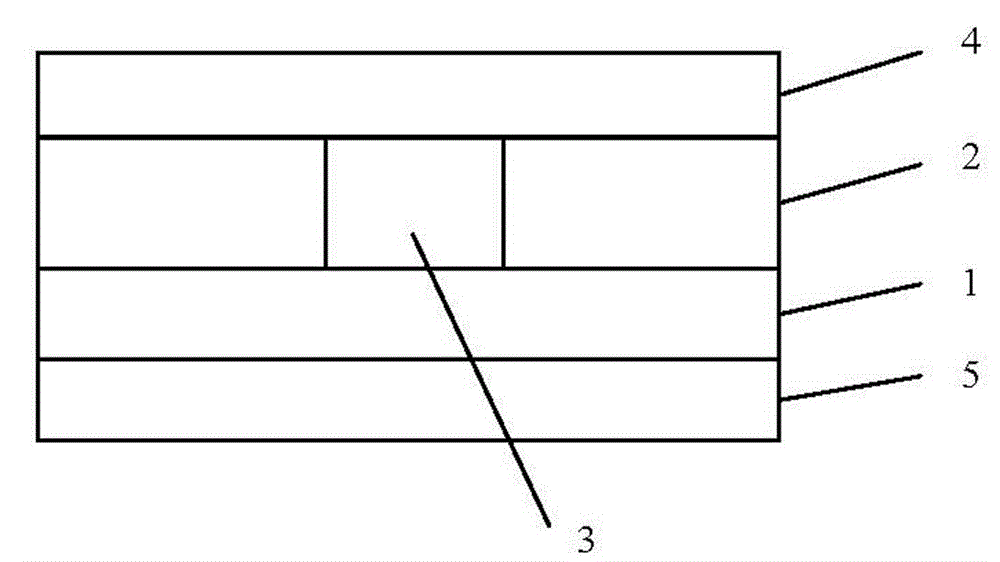

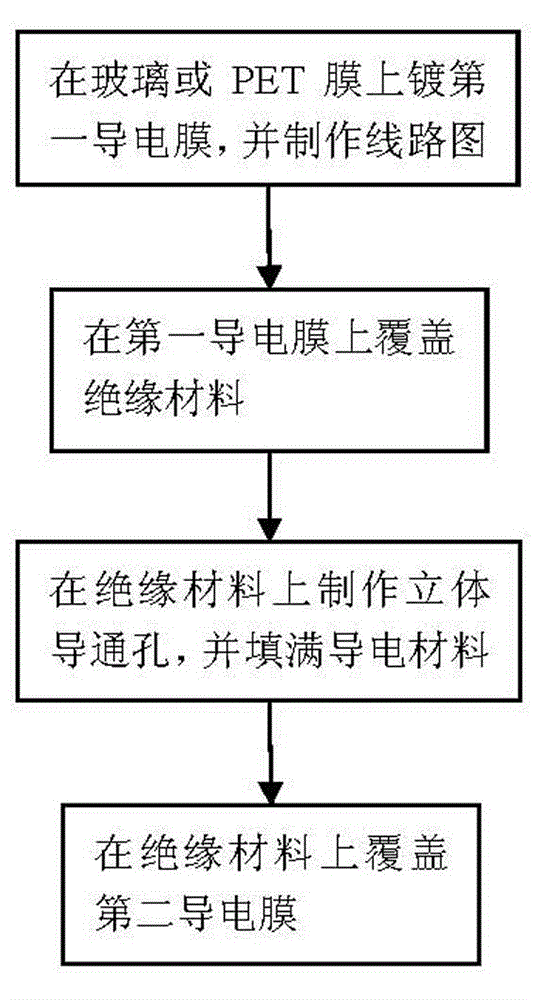

[0015] Such as figure 1 As shown, the capacitive touch screen with three-dimensional via holes proposed by an embodiment of the present invention includes a first conductive film layer 1 plated on a single piece of glass 5 or a PET film, and the first conductive film layer can be indium tin Oxide film or copper film, alloy film and other conductive films, which are plated on glass or PET film by sputtering or electroplating, the thickness of the material itself is very thin, which is very conducive to reducing the overall thickness of capacitive touch screen products . On the first conductive film layer, an insulating layer 2 and a second conductive film layer 4 are successively arranged, and the material used for the insulating layer is a photosensitive or non-photosensitive insulating substance, such as photosensitive or non-photosensitive insulating black ink, insulating white ink or Insulating oil (UV), etc., make the insulating layer very thin. The second conductive film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com