Encapsulation method for semiconductor laser array

A packaging method and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of high power density waste heat, limit the application and operation reliability of semiconductor lasers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

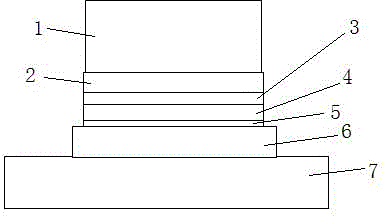

[0019] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation mode combined with its accompanying drawings.

[0020] It can be seen from the attached drawings that the packaging method of the semiconductor laser line array of this scheme is as follows:

[0021] a. Fabrication of insulating films on microchannel coolers;

[0022] b. Prepare solder on the insulating film;

[0023] c. Fixing the semiconductor chip and the microchannel cooler using a jig assembly;

[0024] d. welding the semiconductor chip on the insulating film;

[0025] e. Pressure welding electrode leads.

[0026] Wherein the thickness of the insulating film is 1nm-500nm; the insulating film is a metal oxide film.

[0027] The fixture in step c includes a press block, a bead and a base; the weight of the bead is 5-500 grams; the size of the bead is equal to the size of the semiconductor chip, the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com