Littrow-structure tunable external-cavity laser and mode-hopping-free sweep-frequency regulation method thereof

A laser and cavity-type technology, which is applied in the direction of the device for controlling the output parameters of the laser, the structure of the optical resonator, etc., can solve the problems that the large-scale non-mode-hopping tuning cannot be achieved, and achieve the effect of large-scale non-mode-hopping tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

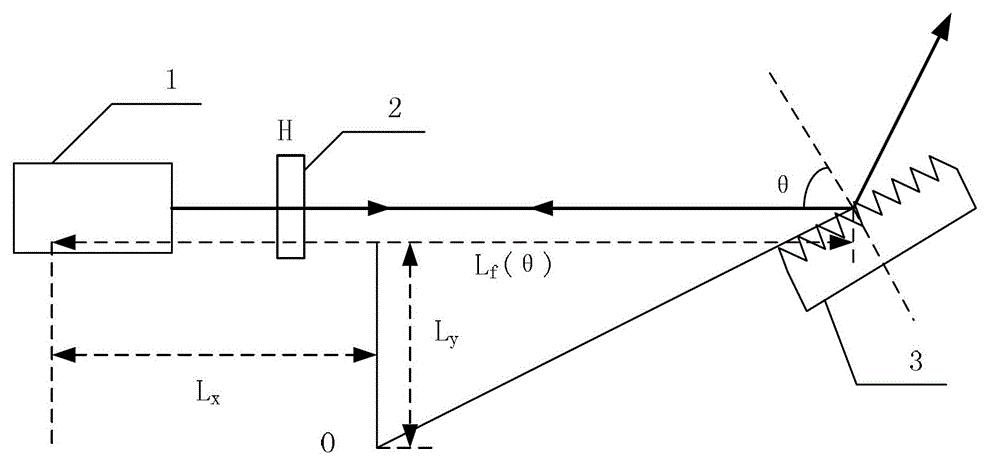

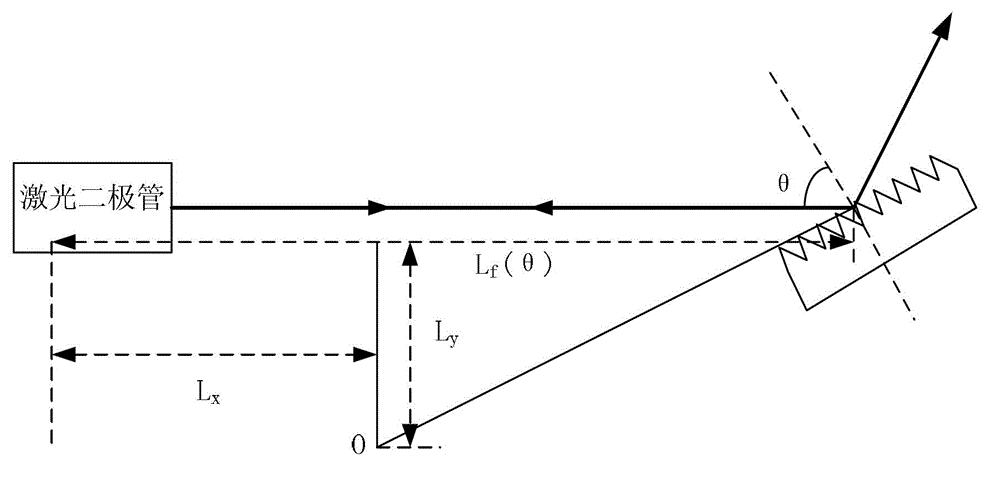

[0024] Specific implementation mode 1: the following combination figure 1 To explain this embodiment, the Littrow structure tunable external cavity laser described in this embodiment includes a semiconductor laser 1, and it also includes a liquid crystal spatial light modulator 2 and a blazed grating 3.

[0025] The laser beam emitted by the semiconductor laser 1 passes through the liquid crystal spatial light modulator 2 and enters the blazed grating 3, and the semiconductor laser 1 and the liquid crystal spatial light modulator 2 are sequentially arranged on the optical axis of the first-order diffraction of the blazed grating 3.

specific Embodiment approach 2

[0026] Specific implementation manner 2: the following combination figure 1 To describe this embodiment, this embodiment is based on the Littrow structure tunable external cavity laser described in the first embodiment.

[0027] The laser beam emitted by the semiconductor laser 1 is incident on the blazed grating 3 after passing through the liquid crystal spatial light modulator 2, and the first-order diffracted light returning from the original path after passing through the blazed grating 3 is in the inner cavity and outside of the tunable external cavity laser. Resonance is formed between the cavities, and finally emitted by the zero order of the blazed grating 3;

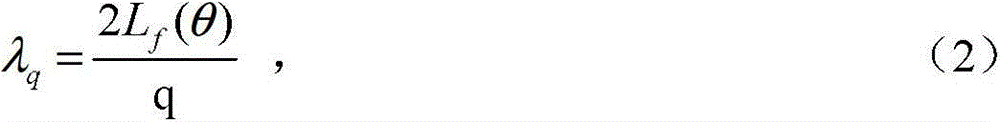

[0028] Rotate the blazed grating 3 around the axis point O, and change the voltage of the liquid crystal spatial light modulator 2 at the same time so that the refractive index n(θ) of the liquid crystal spatial light modulator 2 is:

[0029] n ( θ ) = 2 dq sin θ - 2 L f ( θ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com