Multi-body motor

A stator core and rotor core technology, applied in the field of multi-body motors, can solve the problems that the motor speed cannot be adjusted quickly and conveniently, and achieve the effect of completely consistent power supply time, not easy to vibrate, and low electromagnetic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

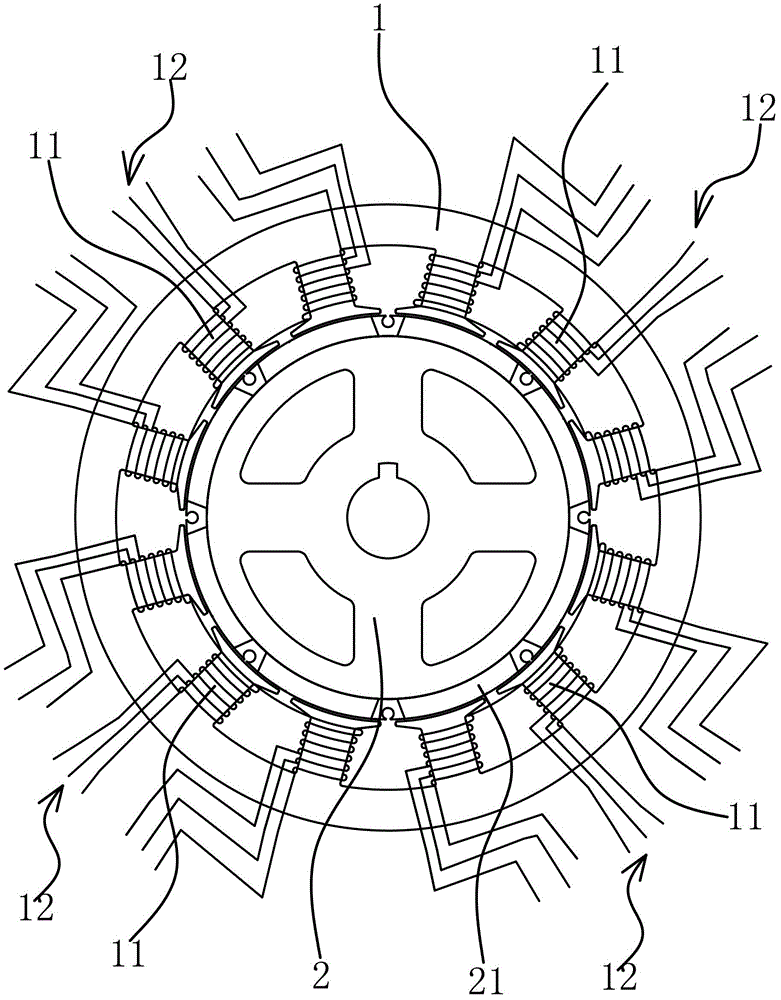

[0034] The multi-piece motor is a new motor structure which is different from the working mode of the existing motors. Among them, the multiple refers to the quantity, that is, to form a motor as a whole with multiple units that can work independently, and to use one or more units to work, so that a motor has different output power, which is equivalent to multiple motors driving the machine together. equipment. The multi-piece motor includes a stator core 1 , a rotor core 2 and an independent stator winding 12 .

[0035] Specifically, as image 3 As shown, the cross section of the stator core 1 is circular, the rotor core 2 is located in the inner circle of the stator core 1 and can rotate relative to the stator core 1 , and the outer peripheral surface of the rotor core 2 is embedded with a magnetic steel sheet 21 . Several coils 11 are evenly arranged on the inner ring of the stator core 1 along the circumferential direction. At least three adjacent coils 11 form an indep...

Embodiment 2

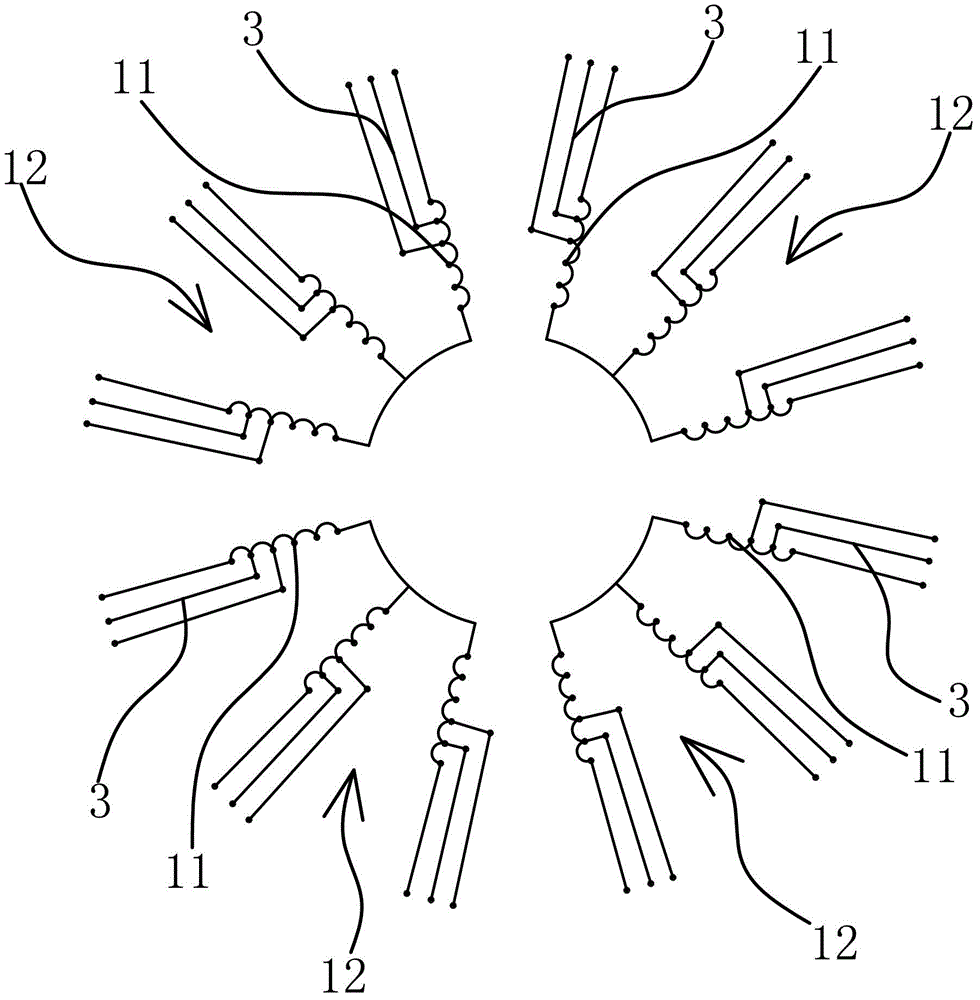

[0039] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, such as Figure 8 As shown, the number of stator windings 12 is six, the number of coils 11 is eighteen, and the number of magnetic steel sheets 21 is twelve.

Embodiment 3

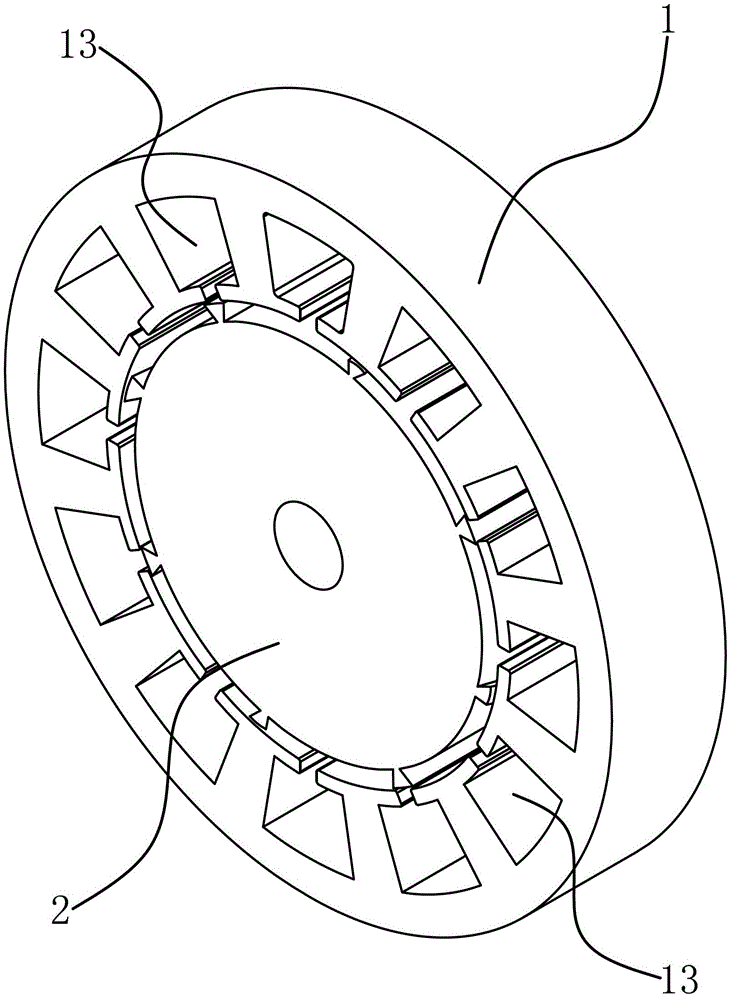

[0041] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, such as Figure 9 As shown, the multi-piece motor has an outer rotor structure, the rotor core 2 is located on the outer ring of the stator core 1, the inner peripheral surface of the rotor core is fixed with magnetic steel sheets, and the stator core 1 has the same number of coils as the coils 11. Slots 13 , the openings of the core slots 13 face outward, the coils 11 are embedded in the corresponding iron core slots 13 , and the magnetic steel sheets 21 are glued to the inner peripheral surface of the rotor core 2 . The working principle of this multi-piece motor is similar to that of the inner rotor motor, that is, the wiring of each stator winding 12 is independent of each other, and can work independently or simultaneously according to the needs of the use, realizing the multi-level power switching of the motor, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com