High-efficiency LED (light emitting diode) driving circuit

A LED driving and high-efficiency technology, applied in the electronic field, can solve the problems of complex power switch tube driving circuit and inaccurate sampling accuracy, and achieve the effects of reducing cost and power consumption, improving modulation accuracy, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

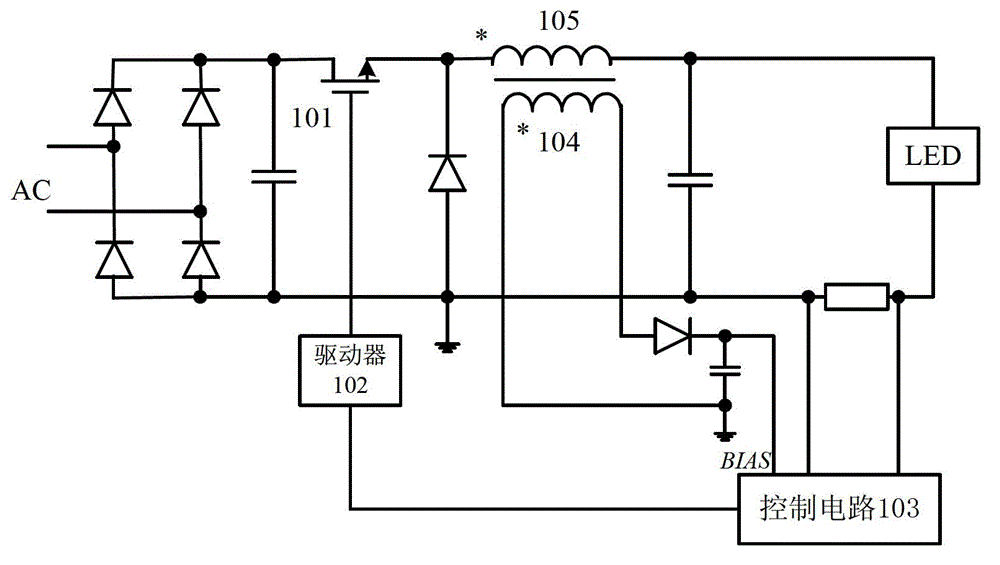

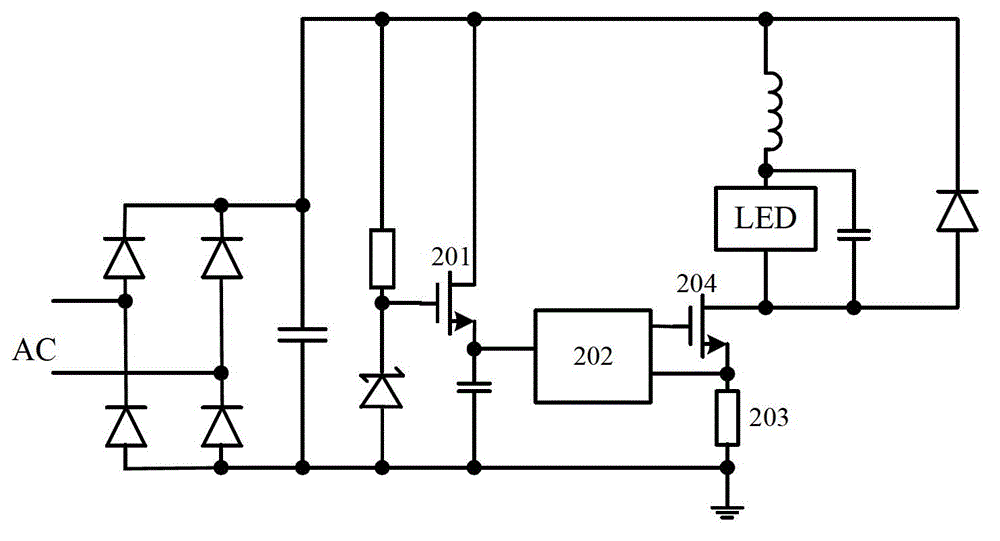

[0049] The LED drive circuit in the embodiment of the present invention is configured as different buck drive circuits and boost-buck drive circuits matching the application by setting different peripheral circuits.

[0050] Various embodiments of the step-down LED driving circuit of the present invention will be described in detail below.

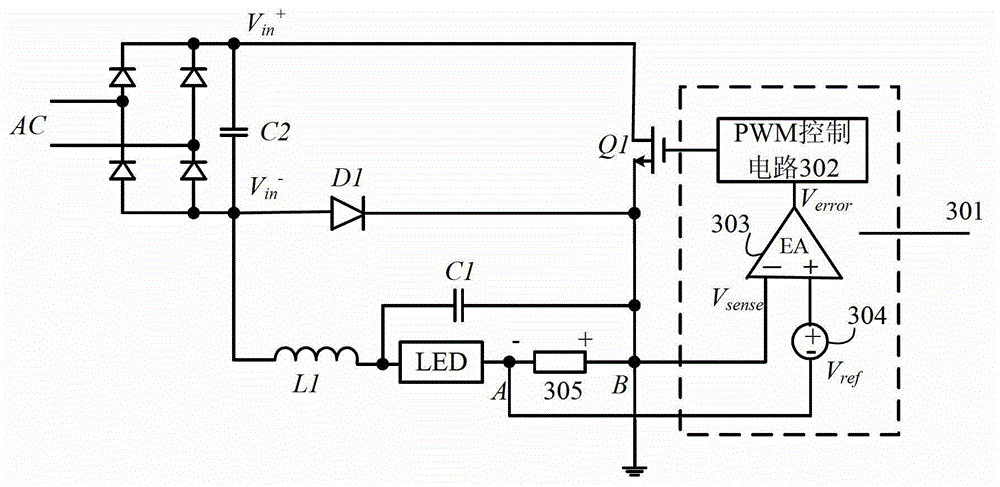

[0051] refer to Figure 3A , which is a functional block diagram of an embodiment of the step-down LED driving circuit of the present invention. In this embodiment, the AC input power supply AC is converted into a DC power supply after passing through the rectifier bridge and the filter capacitor C2, which has a first input level V in + and the second input level V in - .

[0052] The power switch tube Q1, the output diode D1, the output inductor L1, and the output capacitor C1 form a power stage circuit with a step-down topology. Of course, the output capacitor C1 is not necessary, and it can be omitted in some applications. Here, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com