Torque transmission device

A technology of torque transmission device and clutch, applied in the direction of transmission device, differential transmission device, transmission device control, etc., to achieve the effect of low cost, reliable cost and simple stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

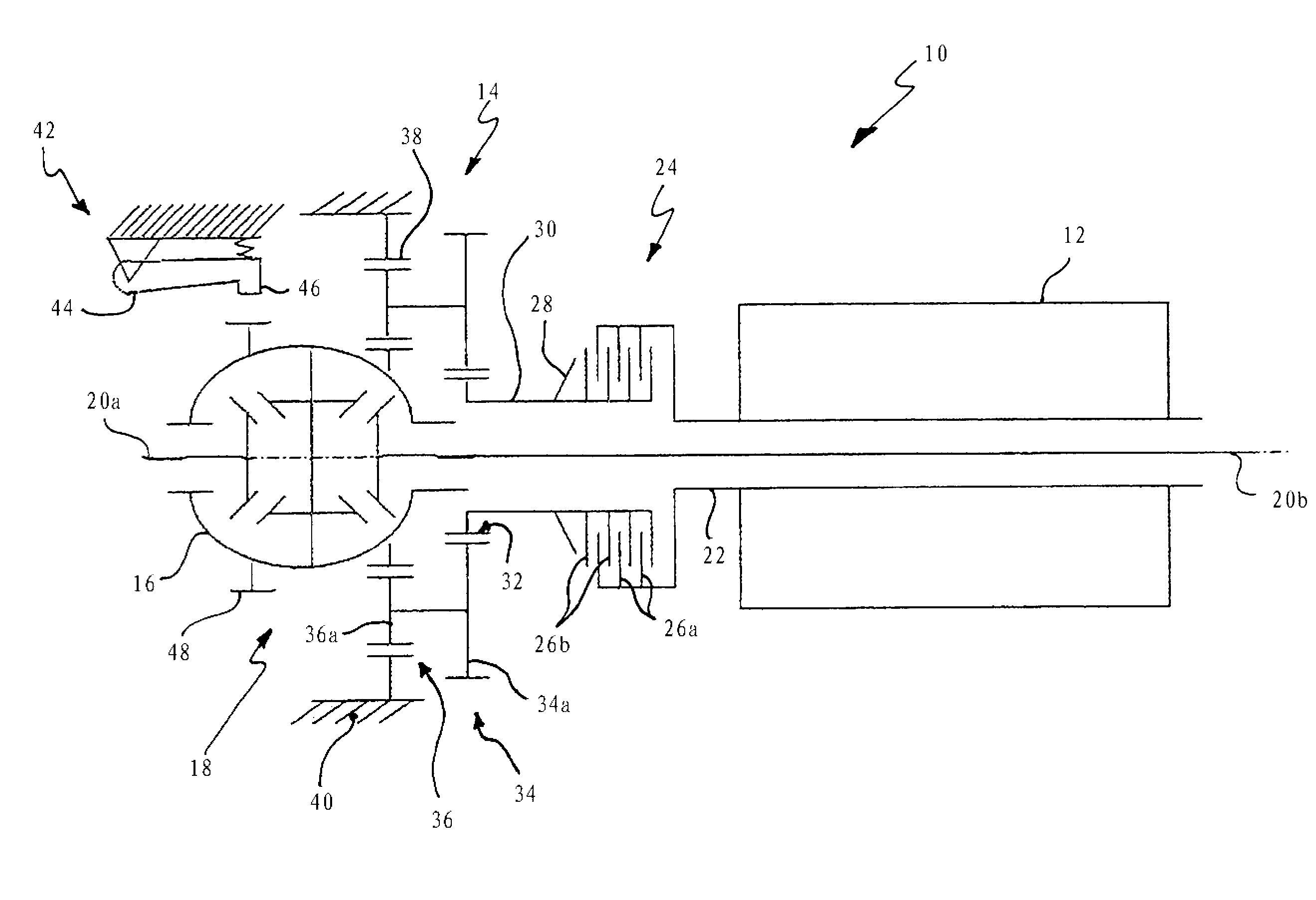

[0017] The driving of the differential mechanism 18 can realize the transmission of the driving torque generated by the electric motor 12 to the half shafts 20a, 20b connected to the wheels of the motor vehicle not shown. The electric motor 12 has a rotor connected to a hollow shaft 22 in a rotationally fixed manner. The hollow shaft 22 is connected to a slip clutch 24 functionally arranged between the electric motor 12 and the speed reducer 14. The slip clutch 24 is designed as a diaphragm clutch and includes alternately arranged outer friction plates 26a and inner friction plates 26b forming a diaphragm stack. The disc spring 28 presses the diaphragms 26a, 26b against each other with a predetermined force so as to provide a clearly defined clutch between the hollow shaft 22 coaxially surrounding the half shaft 20b and the input shaft 30 of the reducer 14.

[0018] The reducer 14 is designed as a two-stage planetary gear transmission. The input shaft 30 is connected to the sun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com