Packing press and nylon tube packing pressing method

A press machine and nylon tube technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate alignment and low product qualification rate, so as to improve production efficiency, solve inaccurate alignment, reduce The effect of the time required for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

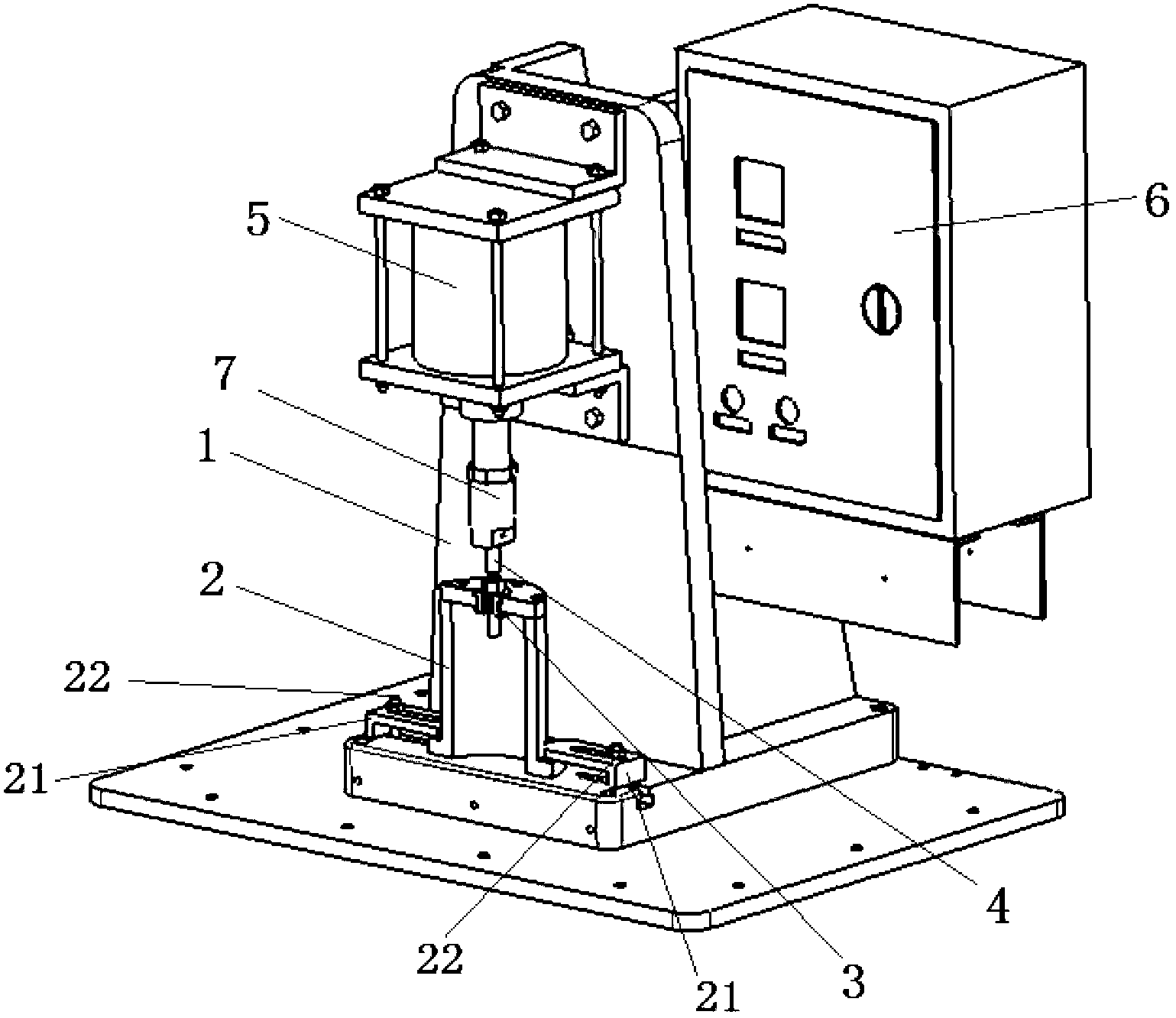

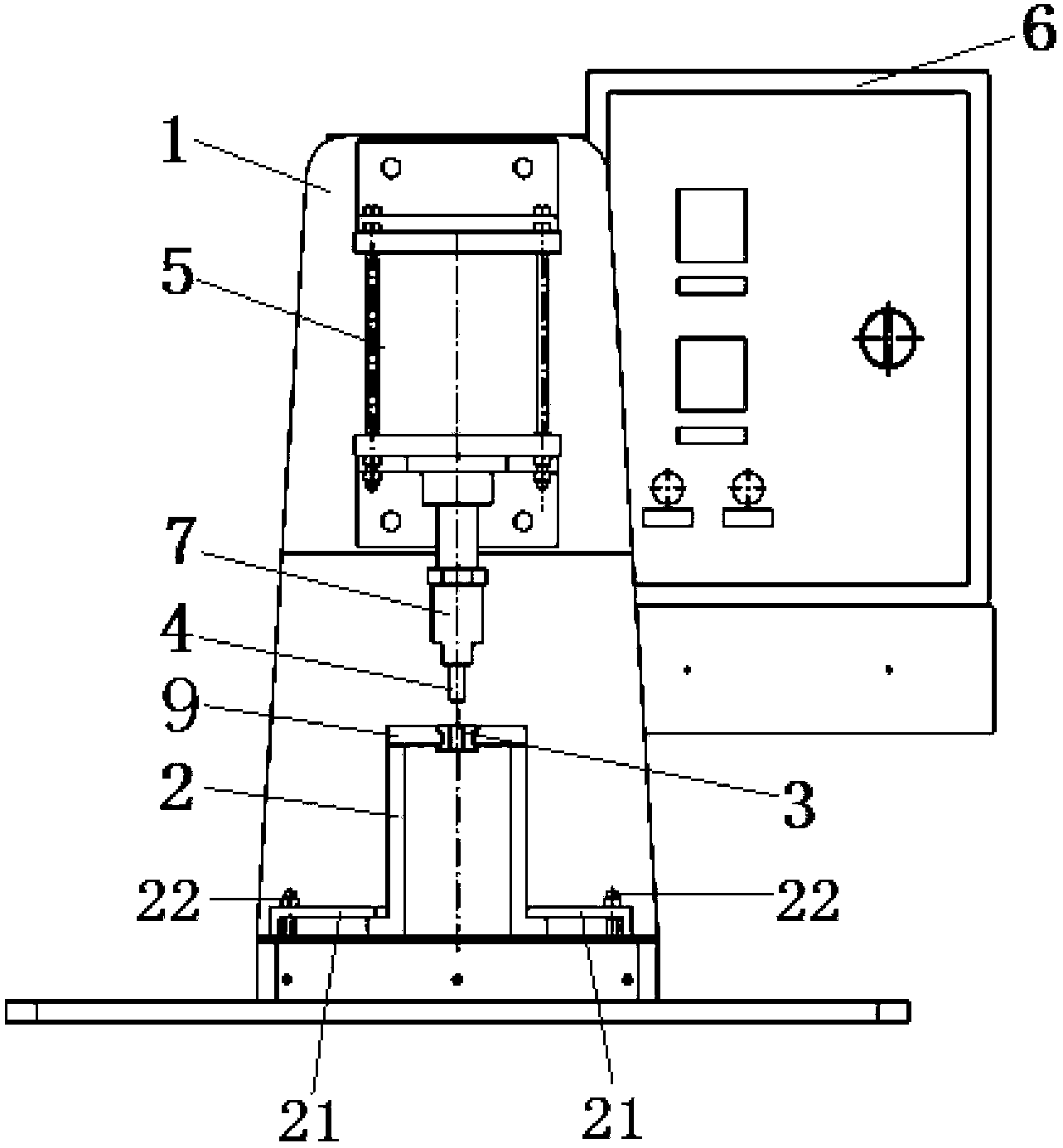

[0033] figure 2 and image 3 All shown are structural schematic diagrams of the press packing machine provided by the present invention. Such as figure 2 , image 3 As shown, the press-fitting machine in this embodiment includes a frame 1 , a support 2 , a bottom mold 3 , a closing mold 4 , a pneumatic cylinder 5 and a controller 6 .

[0034] Wherein: the frame 1 is in an inverted T shape, and the bracket 2 is installed on the bottom plate. The bracket 2 is in the shape of a hollow cylinder, and the cylinder is truncated in half along its axis. The bracket 2 is not limited to the shape of a cylinder, and may also be in other shapes such as a square cylinder. The bracket 2 is fixed on the frame 1 through a pressing plate 21 and screws 22 .

[0035] Bottom mold 3 is the product that can be purchased directly on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com