Winter tire of truck and passenger car

A technology for trucks, buses and tires, applied to tire parts, tire tread/tread pattern, vehicle components, etc., can solve problems affecting tire handling stability, etc., to increase longitudinal rigidity, improve vertical and lateral rigidity, and control tires sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

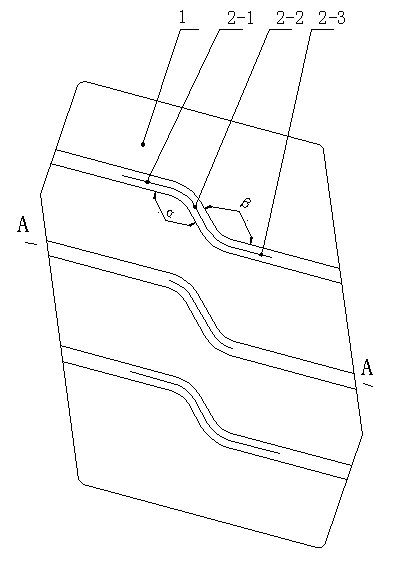

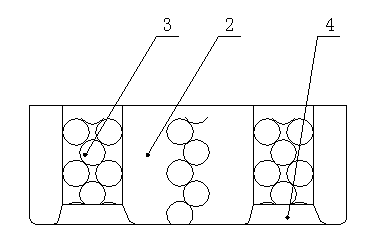

[0012] As shown in the accompanying drawings, a winter truck and bus tire includes a carcass 1, on which a tread ring block 2 is provided, and a tread ring block 2 is provided with a protrusion 3, and the tread ring block 2 Including the first fine pattern 2-1, the middle fine pattern 2-2 and the second fine pattern 2-3 of an integrated structure, the angle between the first fine pattern 2-1 and the middle fine pattern 2-2 is 12° ~140°, the angle between the second fine pattern 2-3 and the middle fine pattern 2-2 is 120~140°, for example: 120, 125, 130, 135 or 140°.

[0013] The structure of the tread pattern block of the present invention can make the tire have a greater bite force on the road surface, and the obtained tire has the stability of longitudinal and lateral rigidity when driving on dry road surface, and can ensure that the tire rolls in the axial direction. The pattern block sipe can be opened freely.

[0014] In the present invention, the protrusion 2 is prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com